Flexible grinding robot for track grinding machining assembly line

An industrial robot and assembly line technology, applied in metal processing equipment, grinding machines, manipulators, etc., can solve problems such as damage to the track body and incomplete welding seam grinding, achieve consistent wear, avoid track damage, and improve grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

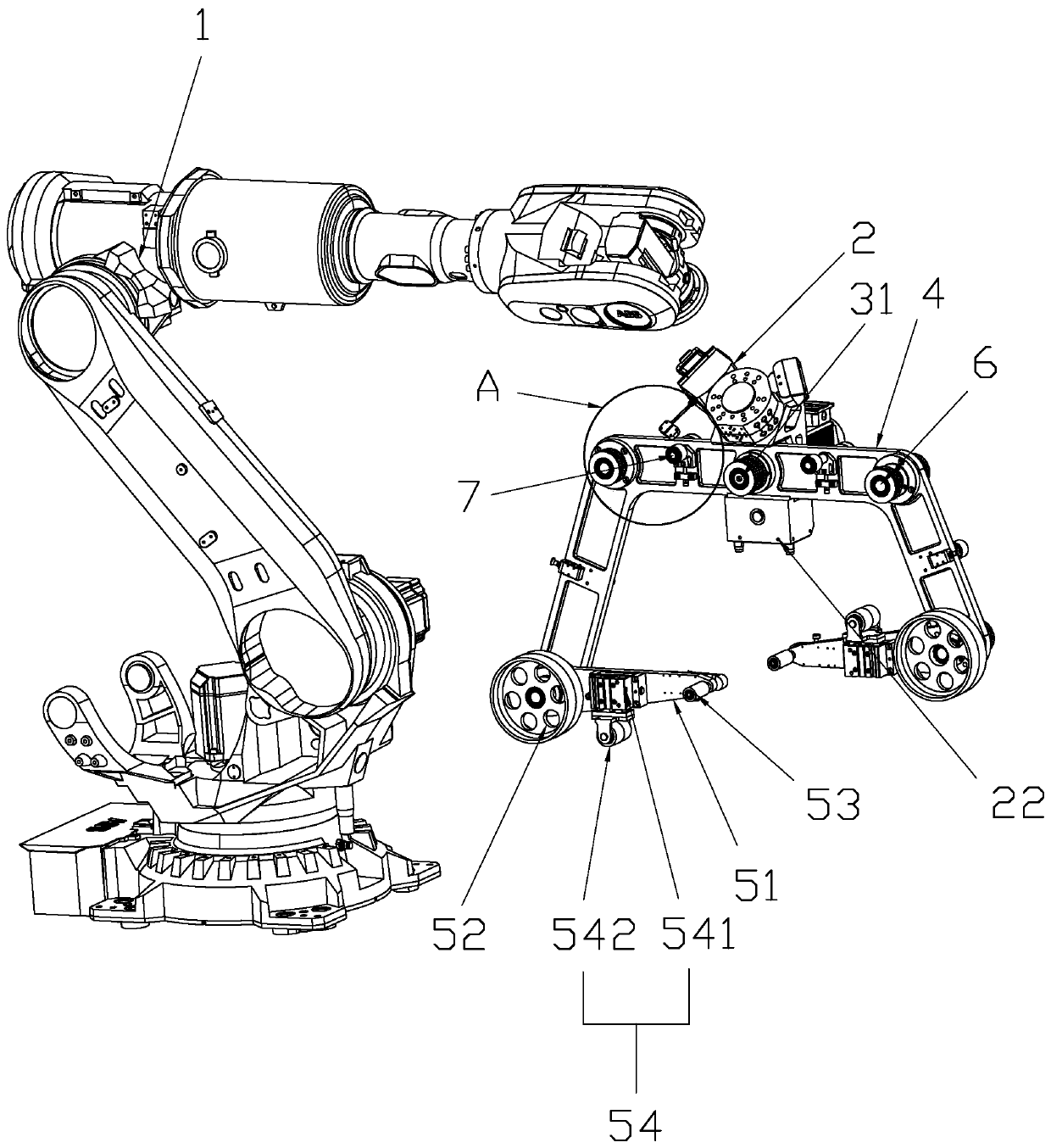

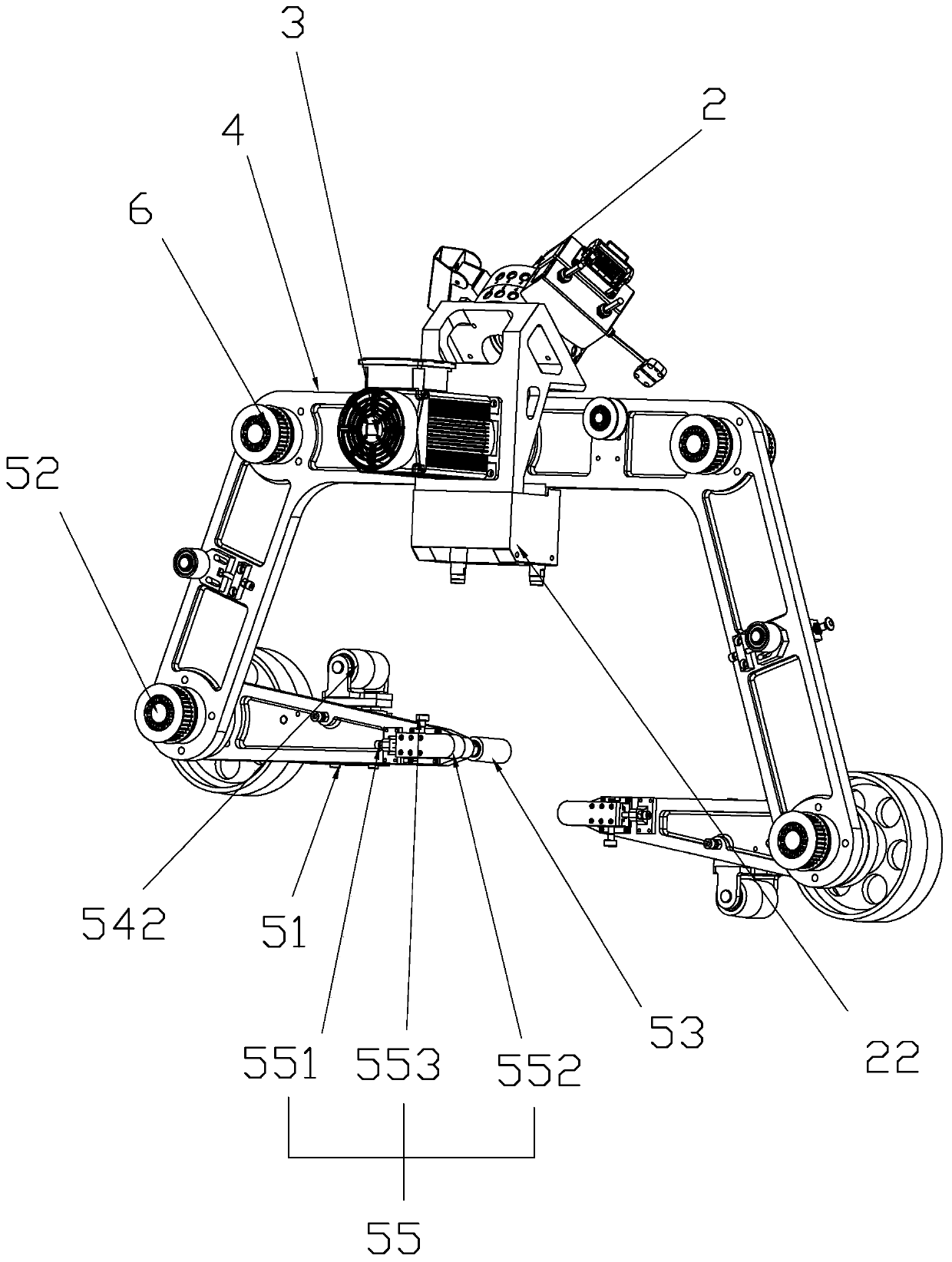

[0028] Such as Figure 1-Figure 6As shown, a flexible grinding robot for a track grinding processing line includes an industrial robot 1 and a flexible grinding device detachably connected to the industrial robot 1. The flexible grinding device includes a connector 2 connected to the end of the industrial robot 1, fixed on The drive motor 3 on the connector, the movable support 4 that is movably connected with the drive motor 3, the abrasive belt wheel assembly 5 that is used to polish the track at the two ends of the movable support 4 and is arranged between the abrasive belt wheel assembly 5 and the drive motor 3 The driving wheel 6, the output end of the driving motor 3 passes through the movable support 4 and the driving wheel 31 is set, and the driving wheel 31 drives the driving wheel 6 to drive the abrasive belt wheel assembly 5 at both ends to operate, and the connecting head 2 corresponds to one end of the movable support 4 There is a flexible grinding space 21 for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com