Mask pack sheet

A technology of facial mask stickers and non-woven fibers, which is applied in the field of facial mask stickers. It can solve the problems of cosmetic compositions such as reduced wettability, no hydrophilicity, and poor stretchability, so as to improve skin adhesion, reduce appearance, and improve moisture and transparency. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

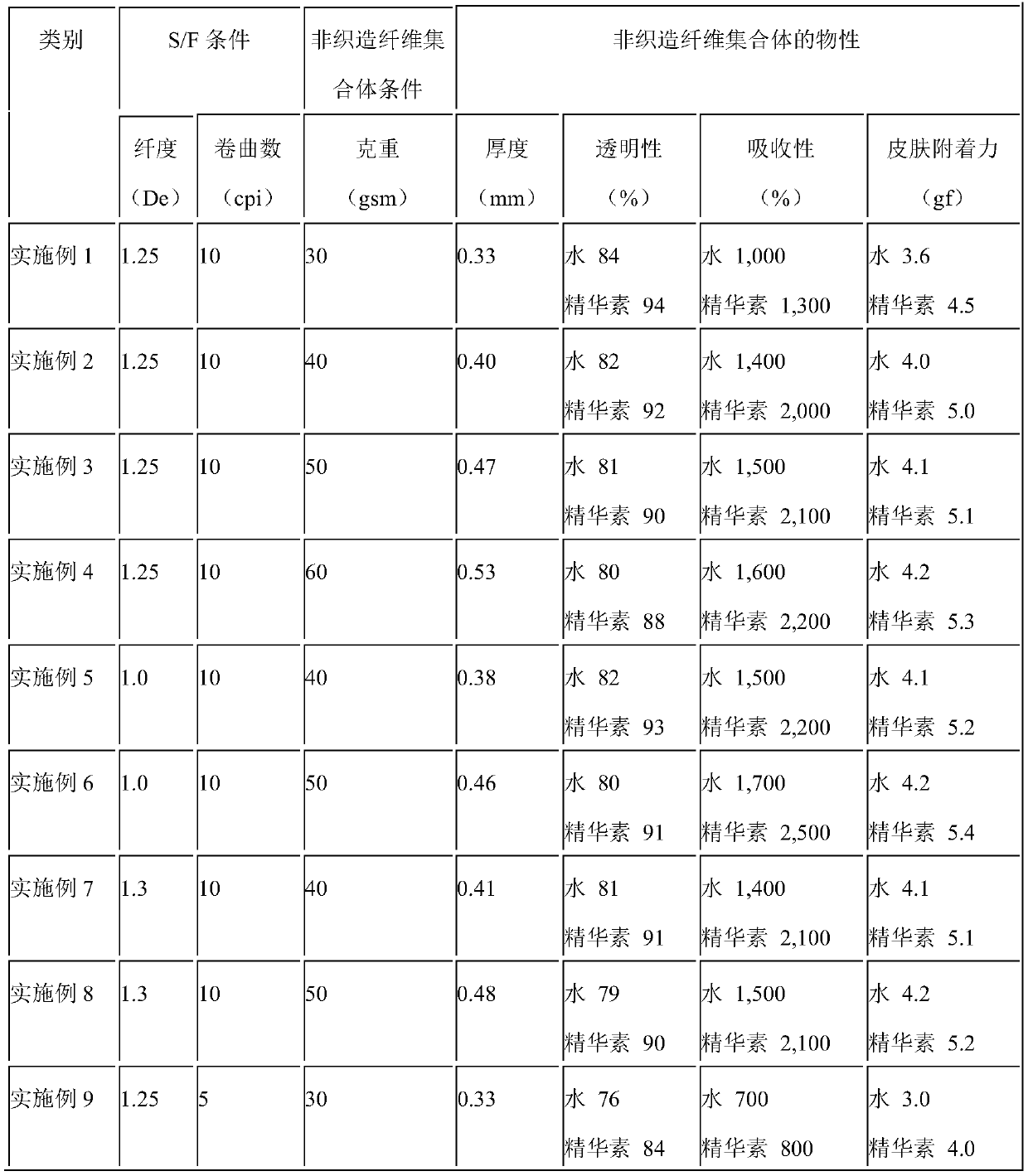

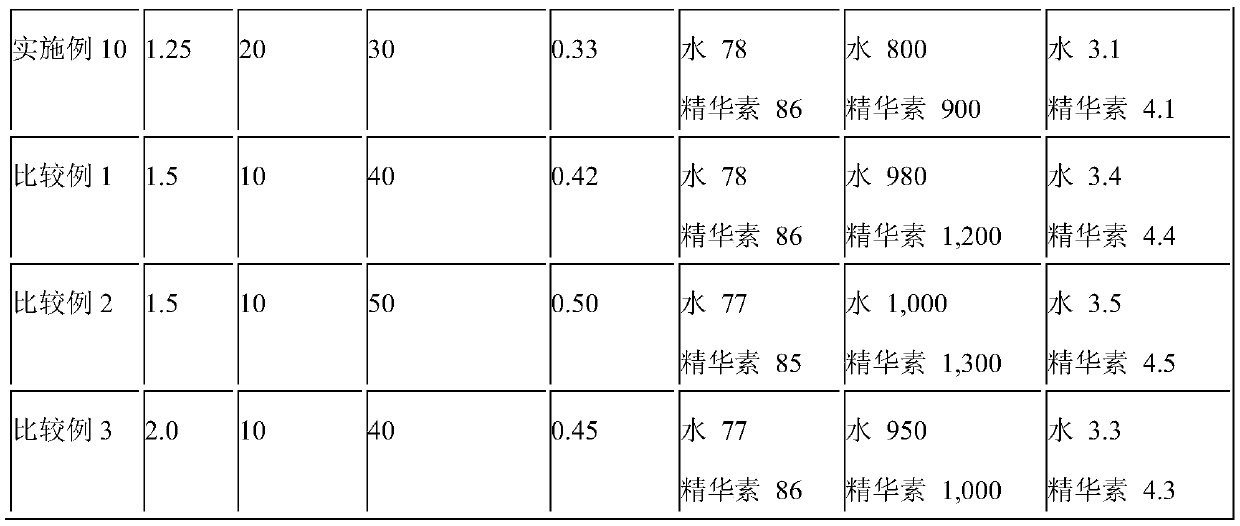

Embodiment 1

[0082] By combining cellulose pulp with a degree of polymerization (DPw) of 820 and an α-cellulose content of 93.9% with NMMO / H with a propyl gallate content of 0.01% by weight 2 O mixed solvents (weight ratio 90 / 10) are mixed to make lyocell fibers with a spinning stock solution whose cellulose pulp content accounts for 10% by weight (spinning stock solution concentration 10%) of the total weight of the mixture.

[0083] First, in the spinning nozzle, while maintaining the spinning temperature of the spinning stock solution at 110°C, the discharge amount of the spinning stock solution and the spinning speed are adjusted to spin so that the single fineness of the filament becomes 1.25 denier you. The filamentous spinning dope discharged from the spinning nozzle continuously passes through the air gap section and is supplied to the coagulation liquid in the coagulation tank. At this time, in the air gap section, the cooling air coagulates the spinning dope for the first time a...

Embodiment 2

[0089] A nonwoven fiber assembly having a single fineness of 1.25 denier was produced in the same manner as in Example 1 except that the basis weight of the nonwoven fiber assembly was adjusted to 40 gsm.

Embodiment 3

[0091] A nonwoven fiber assembly having a single fineness of 1.25 denier was produced in the same manner as in Example 1 except that the basis weight of the nonwoven fiber assembly was adjusted to 50 gsm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com