A kind of asymmetric microchip supercapacitor and preparation method thereof

A microchip, asymmetric technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, multiple hybrid/electric double layer capacitors, etc., can solve the problem of high cost and difficult to achieve precision assembly of asymmetric microchip devices, etc. problems, to achieve the effect of improving efficiency, excellent electrochemical performance, and huge application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

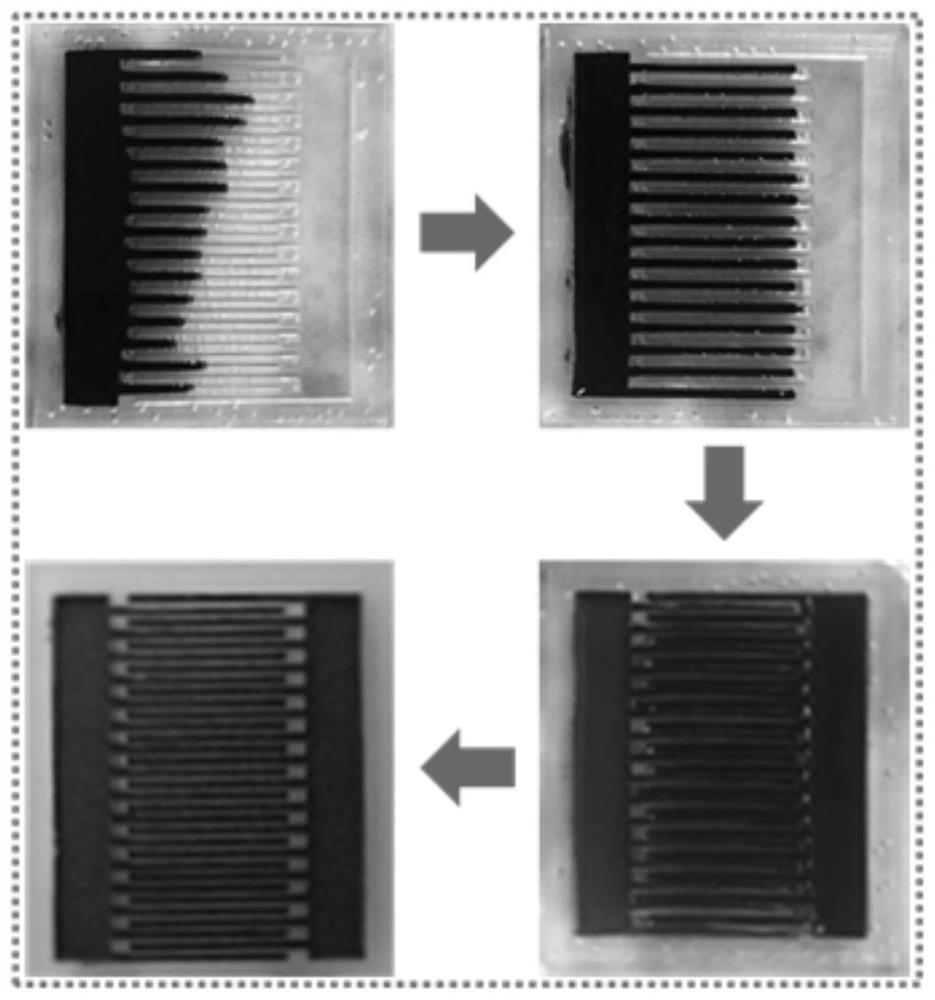

[0033] Laser engraving was used to prepare the template of the microchip structure on the PMMA plate, and then PDMS was poured onto the PMMA template to make a PDMS template with groove and gap widths of 500 microns, and the number of interdigitation pairs was 16. Using SWCNTs / PEDOT:PSS / CuHCF slurry as the cathode material precursor, SWCNTs / PEDOT:PSS / Fe 2 o 3 The slurry is used as the precursor of the negative electrode material to assemble the asymmetric microchip supercapacitor. Before assembly, the PDMS substrate was treated in oxygen plasma for 5min (power 50W) to make its surface hydrophilic. Fill 20 μL of SWCNTs / PEDOT:PSS / CuHCF slurry into one of the grooves of the PDMS substrate, and the slurry will spontaneously enter into the interdigitated grooves under the action of capillary force. After drying at room temperature to the state of no flowing water but not completely dry, add 20 μL of SWCNTs / PEDOT:PSS / CuHCF slurry and dry completely at room temperature. 20 μL SWCN...

Embodiment 2

[0036] Laser engraving was used to prepare the template of the microchip structure on the PMMA plate, and then PDMS was poured onto the PMMA template to make a PDMS template with groove and gap widths of 50 microns, and the number of interdigitation pairs was 20. Using SWCNTs / PEDOT:PSS / CuHCF slurry as the cathode material precursor, SWCNTs / PEDOT:PSS / Fe 2 o 3 The slurry is used as the precursor of the negative electrode material to assemble the asymmetric microchip supercapacitor. Before assembly, the PDMS substrate was treated in oxygen plasma for 1 min (power 50W) to make its surface hydrophilic. Fill 20 μL of SWCNTs / PEDOT:PSS / CuHCF slurry into one of the grooves of the PDMS substrate, and the slurry will spontaneously enter into the interdigitated grooves under the action of capillary force. SWCNTs / PEDOT:PSS / Fe 2 o 3 The slurry was filled into the groove on the other side, and repeated 3 times for the self-assembly of the negative interdigitated film. After the device w...

Embodiment 3

[0039] Laser engraving was used to prepare the template of the microchip structure on the PMMA plate, and then PDMS was poured onto the PMMA template to make a PDMS template with groove and gap widths of 100 microns, and the number of interdigitation pairs was 5. Using SWCNTs / PEDOT:PSS / CuHCF slurry as the cathode material precursor, SWCNTs / PEDOT:PSS / Fe 2 o 3 The slurry is used as the precursor of the negative electrode material to assemble the asymmetric microchip supercapacitor. Before assembly, the PDMS substrate was treated in oxygen plasma for 1 min (power 80W) to make its surface hydrophilic. Fill 30 μL of SWCNTs / PEDOT:PSS / CuHCF slurry into one of the large grooves of the PDMS substrate, and the slurry will spontaneously enter into the interdigitated grooves under the action of capillary force. SWCNTs / PEDOT:PSS / Fe 2 o 3 The slurry was filled into the groove on the other side, and repeated 5 times for self-assembly of the negative electrode interdigitated film. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com