Shock absorption and heat dissipation LED lamp

A technology for LED lights and shock-absorbing strips, applied in lighting and heating equipment, cooling/heating devices for lighting devices, cleaning methods and appliances, etc., can solve the risks brought by LED lights, reduce the working efficiency of LED lights, and reduce LED lights Service life and other issues, to achieve the effect of easy heat dissipation, easy cleaning, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

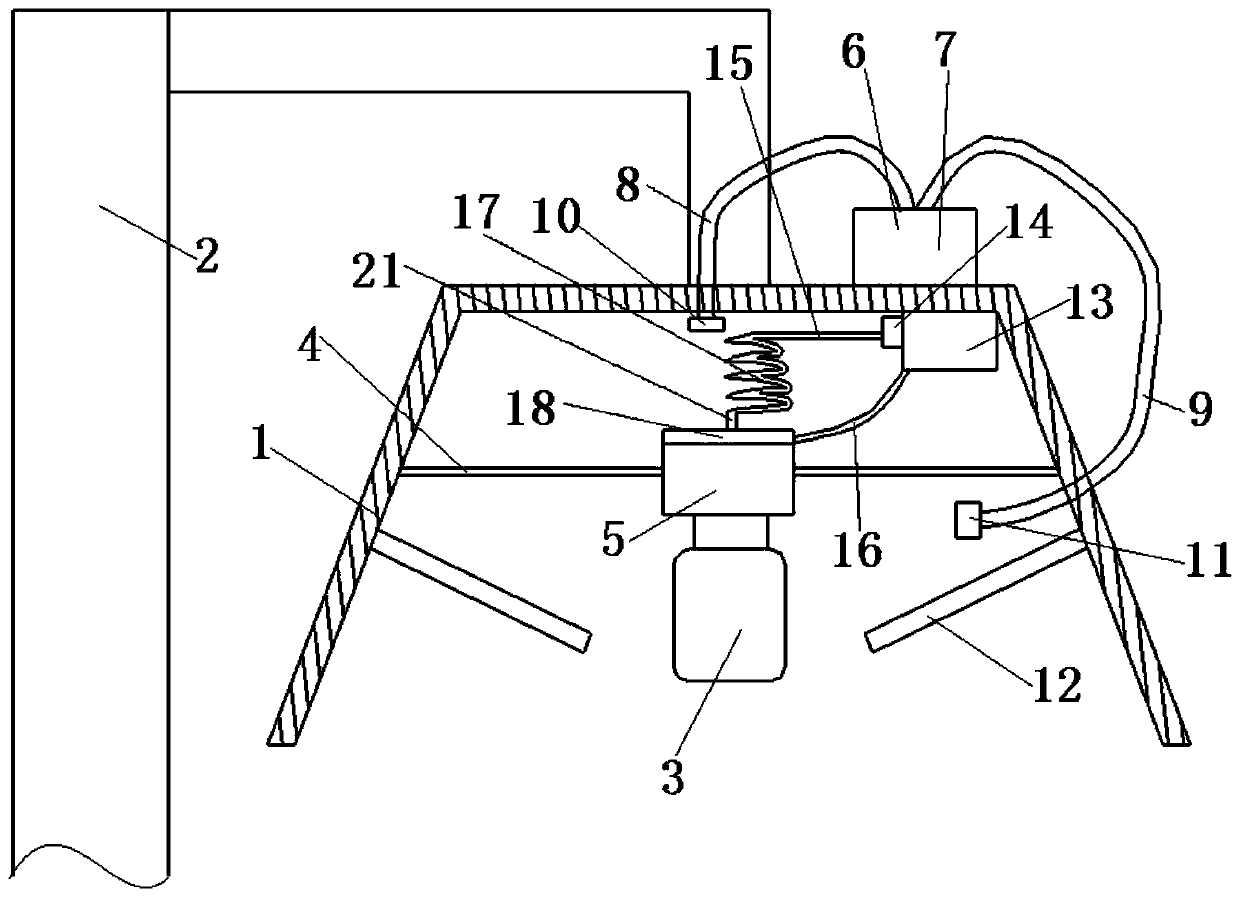

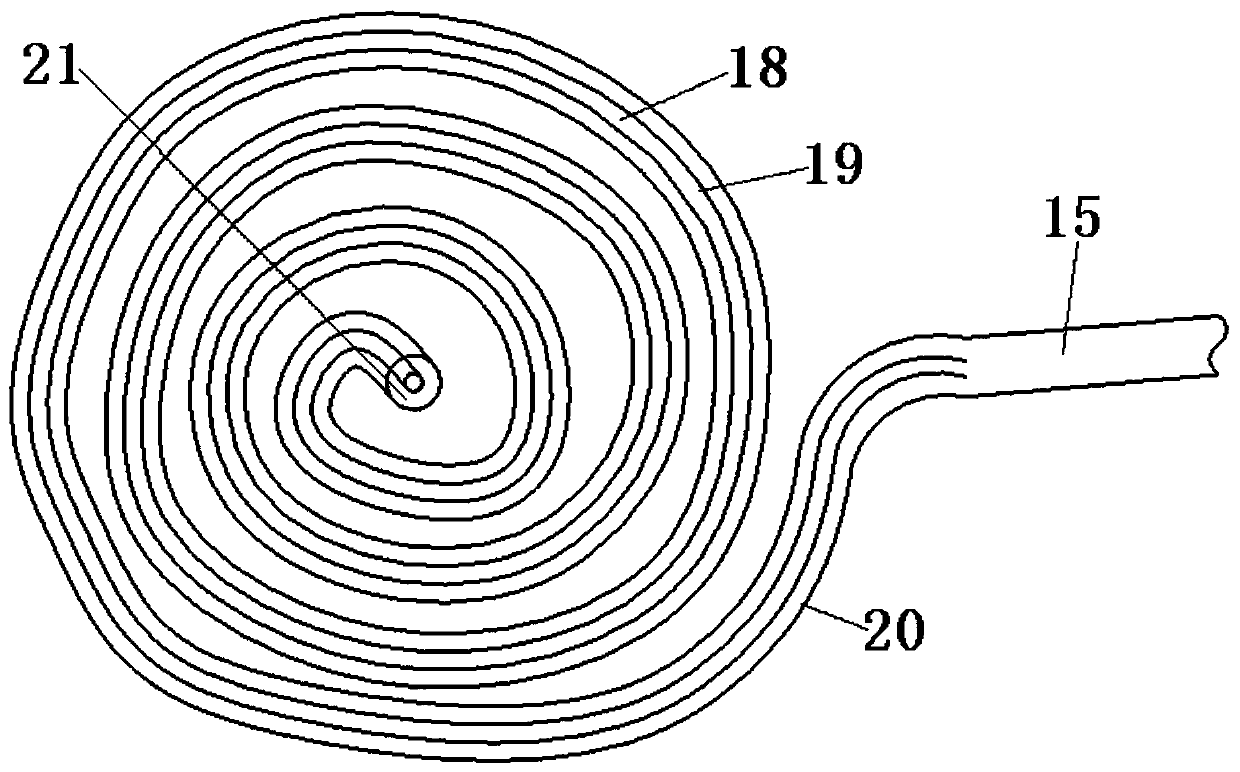

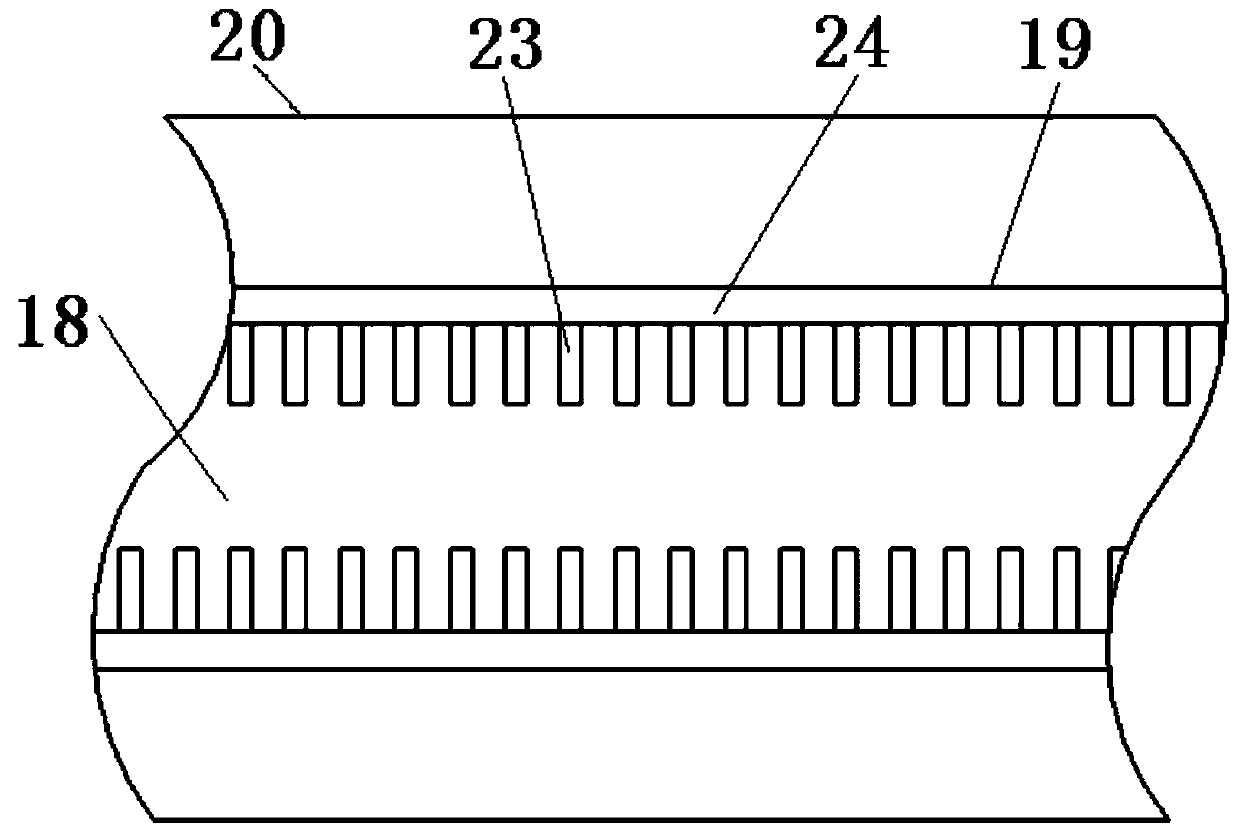

[0029] A shock-absorbing and heat-dissipating LED lamp, comprising a lampshade 1, a support column 2 is provided on one side of the lampshade 1, the lampshade 1 and the support column 2 are connected by a connecting frame, and a central position of the lampshade 1 is provided with The installation platform 5 is connected to the inner wall of the lampshade 1 through a plurality of connecting rods 4, the lower end of the installation platform 5 is detachably connected to the lamp body 3, and the upper end of the lamp body 3 is connected to a snake-shaped double-layer heat dissipation pipe 18. The serpentine double-layer heat dissipation pipe 18 includes a first inner tube 19 and a first outer tube 20, and a first flexible attachment layer 24 is arranged on the inner wall of the first inner tube 19, and the first flexible A plurality of first water-absorbing and shock-absorbing strips 23 are evenly arranged on the attachment layer 24, and a double-layer connection pipe 21 is commu...

no. 2 example

[0039] In order to facilitate the heat dissipation of the lamp body, the lampshade 1 is provided with a first heat dissipation assembly 6, and the first heat dissipation assembly 6 includes a fan and a rotating blade arranged on the first heat dissipation assembly 6, and the fan is arranged on the On the side wall of the lampshade 1, the rotating fan blade is connected with a connecting plate, the upper end of the connecting plate is connected with a rotating shaft, and the upper end of the rotating shaft is connected with the top of the lampshade 1 through a bearing. The connecting plate is a cross section of It is streamlined, and the wind power of the fan is fully utilized to dissipate heat from the lamp body, and at the same time effectively improve the dust removal effect. At the same time, the dust removal effect of the lamp body is enhanced. The cross-section of the connecting plate is streamlined. When the horizontal wind continues to flow at high speed, the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com