Stepped composite reaming and rock waste removal tool

A removal tool, stepped technology, used in drilling equipment, earthwork drilling, drill bits, etc., can solve problems such as affecting the reaming effect, forming mud bags with reaming tools, and well wall collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

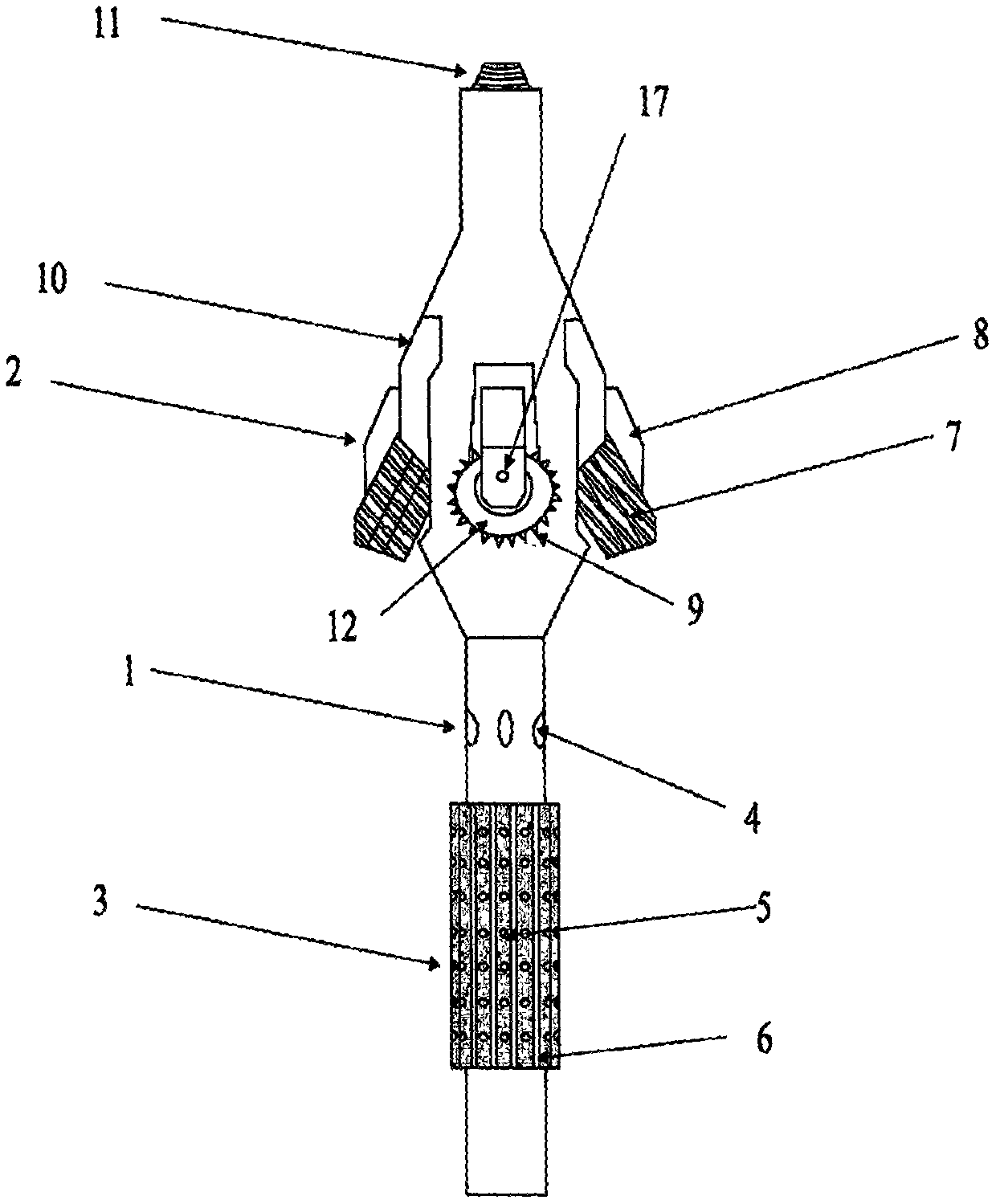

[0019] The following is a clear and complete description of the stepped compound reaming and cuttings removal tool in conjunction with the three accompanying drawings of the present invention.

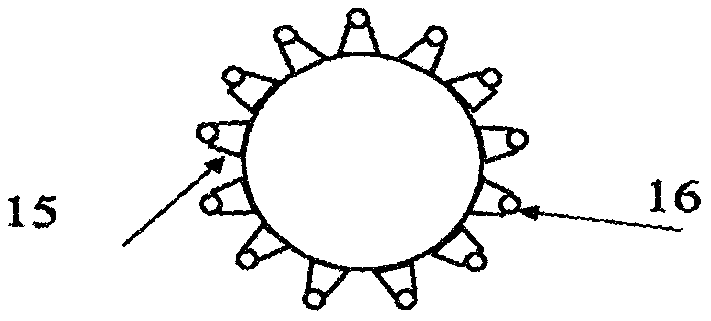

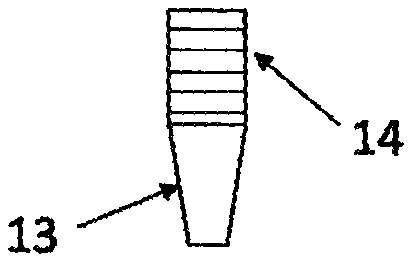

[0020] refer to figure 1 .The step-type compound hole reaming and debris removal tool of the present invention mainly includes (1) water eye, (2) cone reamer, (3) reamer; the (2) cone reamer is located in the tool The upper part is composed of 4 (7) reaming tools, which are evenly distributed around the pipe string, and fixed on the (8) tool holder by (17) bolts. The (7) reaming tools are made of tungsten carbide material, The bolts can be loosened and replaced; during the rotation of the drill string, the 4 (7) reaming tools are constantly rotating to cut and break the formation, and 4 evenly distributed can slow down the wear of each (9) cutting teeth degree, increase the service life, and can play the role of a centralizer to prevent the well deviation, and the use of the roller re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com