High-hardness nodular cast iron roller sheet and casting method thereof

A technology of nodular cast iron and high hardness, which is applied in the field of mechanical casting, can solve the problems of high manufacturing cost, the hardness and service strength of the toothed roller sheet cannot meet the use requirements, and the difficulty of processing, so as to improve the service performance and service life, Effects of improving hardness and uniform distribution of crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

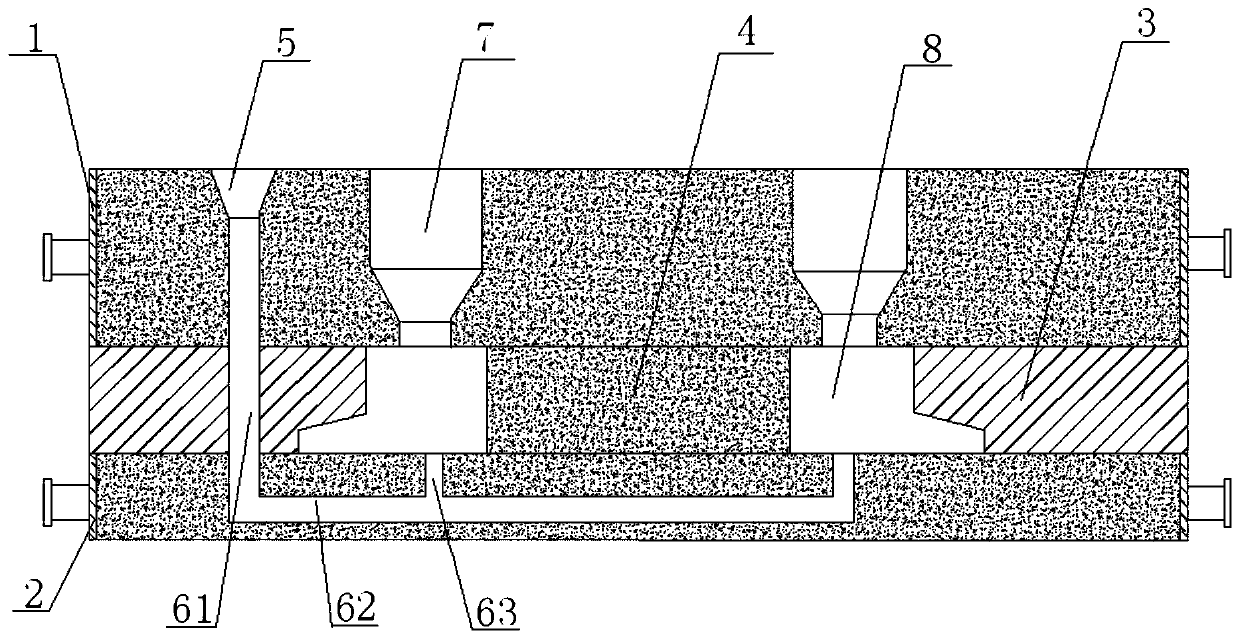

Image

Examples

Embodiment 1

[0043] A high-hardness ductile iron material, including the following chemical composition in mass percentage:

[0044] C 2.9%, Si 1.35%, Mn 0.55%, P0.04%, S0.01%, Cr 0.35%, Mo 0.25%, Ni0.3%, Ba 0.02%, Mg 0.04%, RE 0.01%, the balance is Fe and unavoidable impurities.

[0045] The casting method of the straightener roll sheet with the chemical composition of the above-mentioned high-hardness ductile iron material is:

[0046] a. Add steel scrap, pig iron, carburizer and ferrochrome with a mass ratio of 60:25:1:0.5 into an intermediate frequency electric furnace for smelting to obtain alloy molten iron;

[0047] b. After continuing to heat the alloy molten iron until the temperature reaches 1350°C, add 0.5% ferromolybdenum, 0.3% metallic nickel and 0.5% ferromanganese respectively to obtain the basic pouring solution;

[0048] c. Put 1.1% rare-earth magnesium-silicon alloy in the quality of the basic pouring liquid in the groove at the bottom of the dam bag for casting, cover ...

Embodiment 2

[0054] A high-hardness ductile iron material, including the following chemical composition in mass percentage:

[0055] C 3.2%, Si 1.5%, Mn0.7%, P0.05%, S0.01%, Cr 0.5%, Mo 0.5%, Ni 0.5%, Ba 0.01%, Mg 0.06%, RE 0.02%, the balance is Fe and unavoidable impurities.

[0056] The casting method of the straightener roll sheet with the chemical composition of the above-mentioned high-hardness ductile iron material is:

[0057] a. Add steel scrap, pig iron, recarburizer and ferrochrome with a mass ratio of 65:30:2:1 into an intermediate frequency electric furnace for smelting to obtain alloyed molten iron;

[0058] b. After continuing to heat the alloy molten iron until the temperature reaches 1380°C, add 1% ferromolybdenum, 0.5% metallic nickel and 0.6% ferromanganese respectively to obtain the basic pouring solution;

[0059] c. Put 1.1% rare earth magnesium-silicon alloy in the quality of the basic pouring liquid in the groove at the bottom of the dam bag for casting, cover the ...

Embodiment 3

[0063] A high-hardness ductile iron material, including the following chemical composition in mass percentage:

[0064] C3.4%, Si 1.7%, Mn 0.85%, P0.05%, S0.02%, Cr 0.85%, Mo 0.25%, Ni0.7%, Ba0.02%, Mg 0.07%, RE0.03%, The balance is Fe and unavoidable impurities.

[0065] The casting method of the straightener roll sheet comprising the above-mentioned high-hardness ductile iron material is:

[0066] a. Add steel scrap, pig iron, recarburizer and ferrochrome with a mass ratio of 70:35:3:1.2 into an intermediate frequency electric furnace for smelting to obtain alloy molten iron;

[0067] b. After continuing to heat the alloy molten iron until the temperature reaches 1390°C, add 0.5% ferromolybdenum, 0.7% metallic nickel and 0.8% ferromanganese respectively to obtain the base pouring solution;

[0068] c. Put 1.2% rare-earth magnesium-silicon alloy in the quality of the basic pouring liquid in the groove at the bottom of the dam bag for casting, cover the surface of the rare-e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com