An enhanced ammonia injection denitrification method based on the surface catalytic performance of iron ore pellets

A technology of surface catalysis and iron ore ball, which is applied in the field of iron and steel metallurgy pelletizing process and iron ore pellet flue gas denitration field, which can solve the problems of low efficiency of ammonia spraying and denitration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

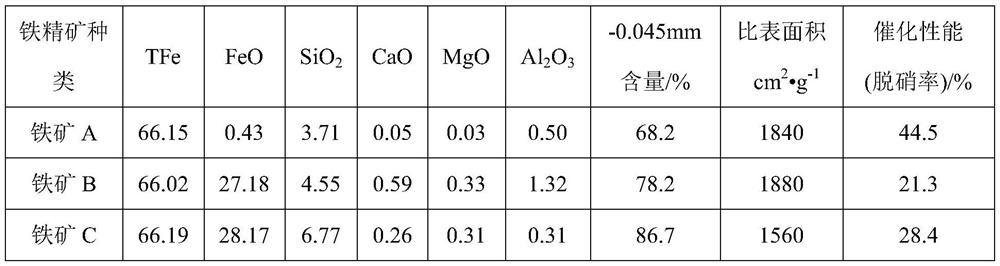

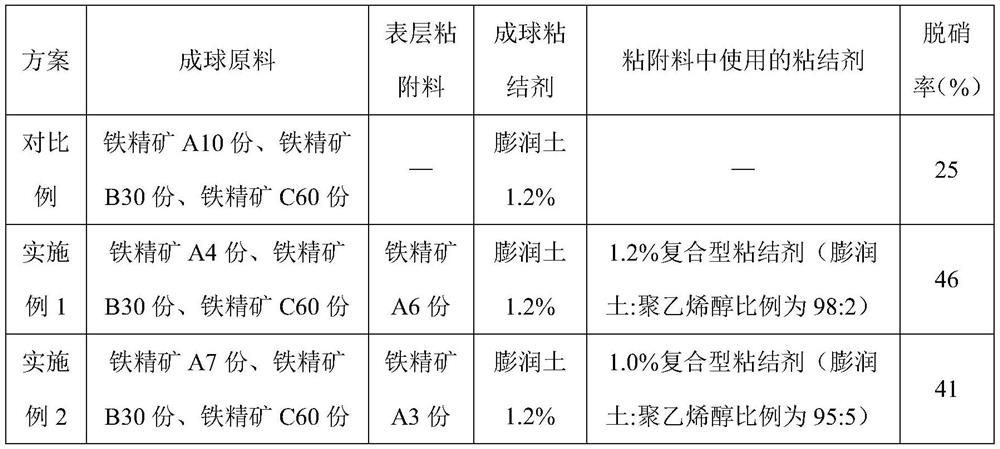

Embodiment 1

[0045] The proportioning scheme of pelletizing raw materials of the present invention is that the ratio of iron concentrate A: iron concentrate B: iron concentrate C is 10:30:60, and iron concentrate A is a strong catalytic iron concentrate, and 6% of it is separated Iron concentrate A is used for pellet surface adhesion, and the remaining iron concentrate is prepared by adding 1.2% bentonite to the mixed iron concentrate after blending to prepare 12-16mm pellets, and then blended into the separated iron concentrate A Add 1.2% composite binder, the ratio of bentonite to polyvinyl alcohol in the composite binder is 98:2, add it to the large ball growth area of the pelletizing disk, and adhere it to the pellet surface of 12-16mm , to form green pellets with a strong catalytic iron concentrate surface layer containing a composite binder; the grate machine-rotary kiln pellet production process is adopted, and the pipeline is set in the hood of the exhaust drying section at a temp...

Embodiment 2

[0047] The ratio of pellet raw materials is iron concentrate A: iron concentrate B: iron concentrate C ratio is 10:30:60, iron concentrate A is a strong catalytic iron concentrate, and 3% of the iron concentrate is separated Ore A is used for the adhesion of the surface layer of the pellets. After the remaining iron concentrate is blended, 1.2% bentonite is added to the mixed iron concentrate to prepare a 12-16mm pellet, and then 1.0% bentonite is added to the separated iron concentrate A. % Composite binder, the ratio of bentonite and polyvinyl alcohol in the composite binder is 95:5, and after mixing, add it to the large ball growth area of the pelletizing disc to make it adhere to 12 -16mm pellet surface, forming green pellets with a strong catalytic iron concentrate surface layer containing a composite binder; the chain grate-rotary kiln pellet production process is adopted, and the smoke is smoked in the ventilation drying section at a temperature of 350°C A pipeline is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com