Water-absorbing rubber composite material and preparation method thereof

A composite material and rubber technology, which is applied in the field of water-absorbing rubber composite materials and its preparation, can solve the problems that it is difficult to satisfy water-absorbing rubber composite materials, it is difficult to quickly reach the state of water absorption balance, and the water absorption effect is not very ideal, so as to achieve good water absorption ratio and good Excellent water absorption rate and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

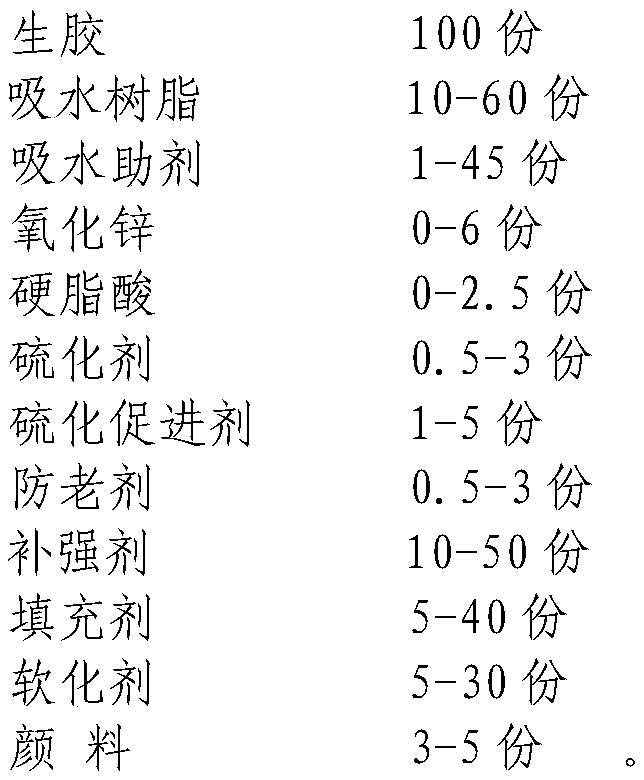

[0040] A water-absorbing rubber composite material, the composite material components include, in parts by mass:

[0041]

[0042] Concrete preparation steps are as follows:

[0043]Preparation of water-absorbing additives: first place glycerin fatty acid ester in an oven at 20°C for 2 hours, select 375g of white carbon black, 750g of bentonite, 250g of PEG1500, 125g of superfine talc powder and 1000g of baked glycerin fatty acid ester into Mix and stir in a high-speed mixer for 8 seconds, control the stirring speed of the mixer to 15000r / min, then discharge to obtain a water-absorbing aid, and set aside;

[0044] Rubber mixing: masticate the raw rubber for 1.5 minutes in a double-roller mixer, then add zinc oxide, stearic acid, vulcanization accelerator, anti-aging agent, and pigment in sequence, cut left and right three times, and then add reinforcing agent and softener , filler, water-absorbing agent, and polyacrylamide water-absorbing resin are added in sequence, the l...

Embodiment 2

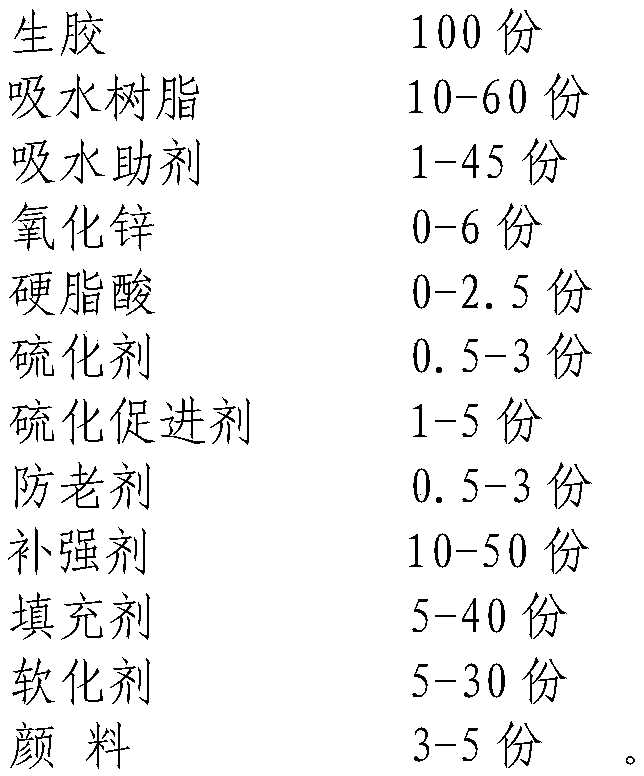

[0047] A water-absorbing rubber composite material, the composite material components include, in parts by mass:

[0048]

[0049] Concrete preparation steps are as follows:

[0050] Preparation of water-absorbing aid: After placing propylene glycol fatty acid ester in an oven at 25°C for 1 hour, take 625g of white carbon black, 500g of bentonite, 200g of PEG4000, 100g of superfine talcum powder and 625g of baked propylene glycol fatty acid ester and send them into high-speed mixing Mix and stir in the machine for 3 seconds, control the stirring speed of the mixer to 25000r / min, and then discharge the material to obtain the water-absorbing aid, which is set aside.

[0051] Rubber mixing: masticate the raw rubber for 1.5 minutes in a double-roller mixer, then add zinc oxide, stearic acid, vulcanization accelerator, anti-aging agent, and pigment in sequence, cut left and right three times, and then add reinforcing agent and softener , fillers, water-absorbing additives, and ...

Embodiment 3

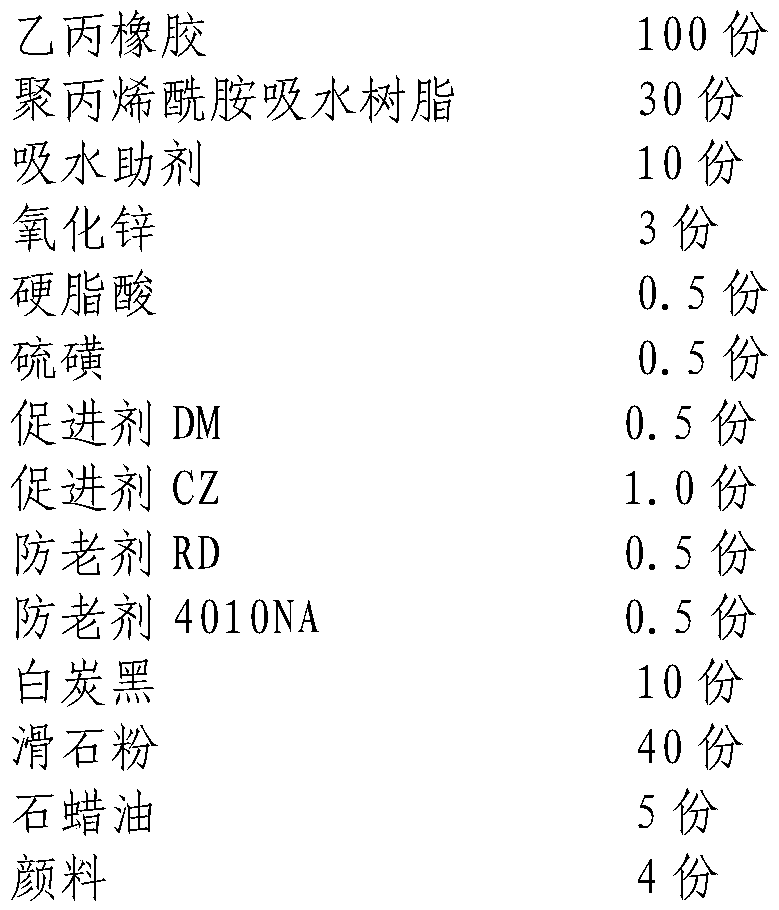

[0054] A water-absorbing rubber composite material, the composite material components include, in parts by mass:

[0055]

[0056] Concrete preparation steps are as follows:

[0057] Preparation of water-absorbing aid: After placing sucrose fatty acid ester in an oven at 25°C for 1.5 hours, take 1000g of white carbon black, 125g of bentonite, 50g of PEG6000, 60g of superfine talcum powder and 375g of baked sucrose fatty acid ester and send it into a high-speed Mix and stir in the mixer for 5s, control the stirring speed of the mixer to 20000r / min, and then discharge to obtain a multi-functional water-absorbing aid, which is set aside;

[0058] Rubber mixing: masticate the raw rubber for 1.5 minutes in a double-roller mixer, then add zinc oxide, stearic acid, vulcanization accelerator, anti-aging agent, and pigment in sequence, cut left and right three times, and then add reinforcing agent and softener , fillers, water-absorbing additives, acrylic acid / acrylamide copolymer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com