Electrochemical-biological coupling closed-circuit treatment method and device for surplus sludge/digestive liquid

A technology for excess sludge and treatment equipment, which is applied in the direction of electrochemical-biological combination treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of increasing system load, affecting the operation of sewage treatment system, and high cost , to achieve the effect of efficient coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

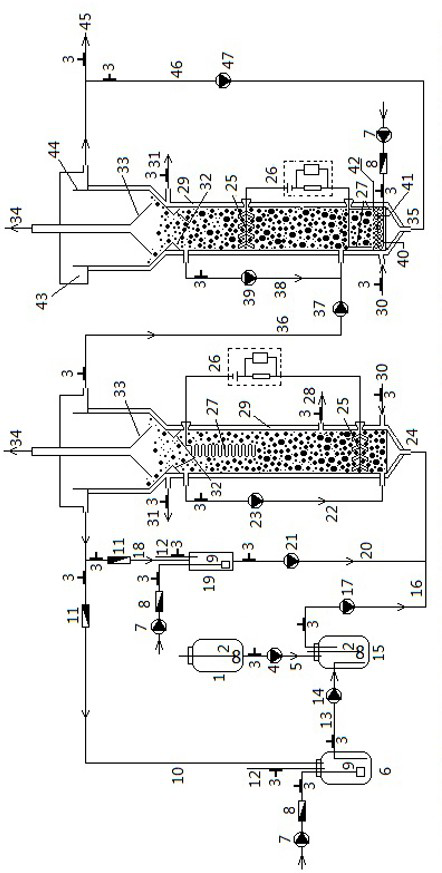

[0086] figure 1 The specific structure of the electrochemical-biological coupling excess sludge / digestive liquid closed-circuit treatment device of the present invention is given, consisting of FNA in-situ generation pool 6, excess sludge FNA pretreatment pool 15, excess sludge treatment reactor 24 and digestive liquid The treatment reactor 35 is formed and equipped with a sludge storage tank 1 and an aeration return column 19 .

[0087] Wherein, the excess sludge treatment reactor 24 and the digestive liquid treatment reactor 35 are both made of plexiglass.

[0088] The excess sludge treatment reactor 24 includes two parts: a reaction zone and a sedimentation zone, and the digestive liquid treatment reactor 35 includes three parts: an aeration distribution chamber 41 , a reaction zone and a sedimentation zone. Among them, the inner diameter of the aeration distribution chamber 41 is 100mm, the height is 0.2m, and the volume is 1.5L; the inner diameter of the reaction zone is...

Embodiment 2

[0108] Take the excess sludge from the former Taiyuan Yangjiabao Sewage Treatment Plant as the excess sludge to be treated. The solid content of the excess sludge is 16%, TS=176.6g∙L -1 , VS=122.8g∙L -1 , VS / TS=0.69.

[0109] The granular sludge is taken from the highly efficient and stable granular sludge reactor (EGSB reactor) for treating urban domestic sewage, and is used to fill the excess sludge treatment reactor and the digestive liquid treatment reactor.

[0110] Micro-aerobic aeration to ensure FNA in-situ production of 0.06mg∙L in the tank -1 FNA (25°C, pH 6.8), the effluent from the FNA in-situ generation pool and the remaining sludge to be treated enter the excess sludge FNA pretreatment tank at the same time, and the pretreatment reaction is 4 hours (FNA pretreats the excess sludge). After pretreatment The excess sludge enters the excess sludge treatment reactor (at this time, the electrode is still in the state of acclimating and cultivating electricity-produci...

Embodiment 3

[0121] Take the excess sludge from the former Taiyuan Yangjiabao Sewage Treatment Plant as the excess sludge to be treated. The solid content of the excess sludge is 16%, TS=176.6g∙L -1 , VS=122.8g∙L -1 , VS / TS=0.69.

[0122] Granular sludge is taken from the highly efficient and stable granular sludge reactor (EGSB reactor) for treating urban domestic sewage to fill the remaining sludge treatment reactor and digestive liquid treatment reactor.

[0123] Micro-aerobic aeration to ensure FNA in-situ production of 0.15mg∙L in the tank -1 FNA (25°C, pH 6.8), the effluent from the FNA in-situ generation pool and the remaining sludge to be treated enter the excess sludge FNA pretreatment tank at the same time, and the pretreatment reaction is 4 hours (FNA pretreats the excess sludge). After pretreatment The excess sludge enters the excess sludge treatment reactor (the electrode is in the state of acclimating and cultivating electricity-producing functional bacteria externally (dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com