A kind of preparation method of wooden fireproof door and wooden fireproof door

A fire door and wood technology, applied in the field of fire doors, can solve the problems of perlite particles falling off, scattered and accumulated in the space of the door frame, collision, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

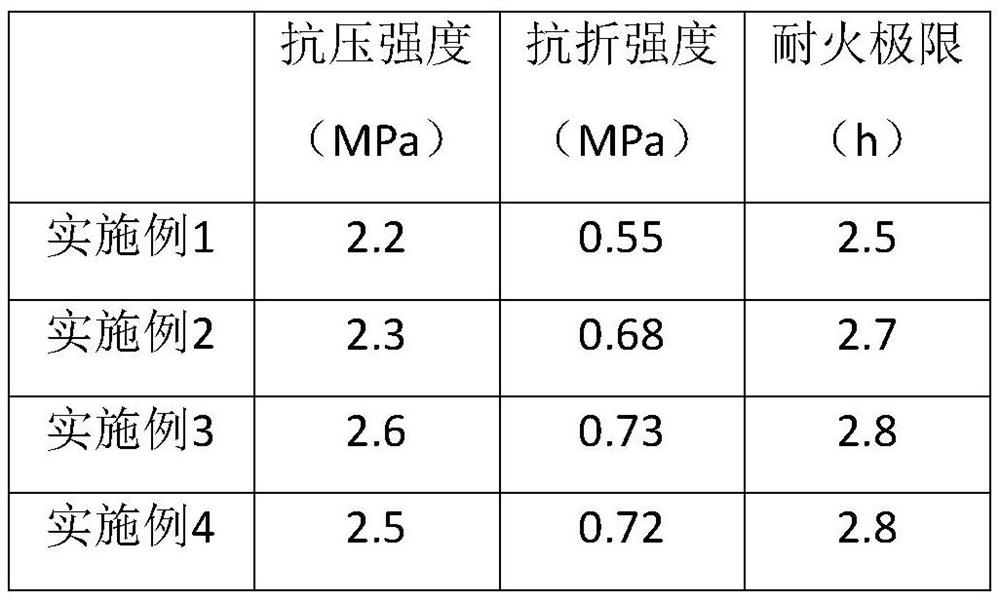

Examples

Embodiment 1

[0040] The preparation method of the wooden fireproof door of the present embodiment comprises the steps:

[0041] 1) Use pine blanks to prepare a wooden skeleton. The wooden skeleton is a "mesh"-shaped frame, including two longitudinal beams and four cross beams. Evenly spaced in the extension direction. The length of the wooden skeleton is 225cm and the width is 91cm.

[0042] 2) Mix and stir alumina powder, aluminum phosphate, and phosphoric acid with a mass fraction of 10% in a mass ratio of 1:1:10, then add water to dilute it by 3 times and pour it into the dipping tank, and immerse the wooden skeleton in the dipping tank for 30 minutes. Take it out, and dry it with hot air at 80°C for 2 hours to prepare a flame-retardant wooden skeleton.

[0043] 3) Take a fireproof decorative board, which is a rectangular board with a length of 230cm and a width of 95cm. The size of the fire-resistant decorative board is slightly larger than the flame-retardant wooden skeleton, so th...

Embodiment 2

[0052] The preparation method of the wooden fireproof door of the present embodiment comprises the steps:

[0053] 1) Use pine blanks to prepare a wooden skeleton. The wooden skeleton is a "mesh"-shaped frame, including two longitudinal beams and four cross beams. Evenly spaced in the extension direction. The length of the wooden skeleton is 225cm and the width is 91cm.

[0054] 2) Mix and stir alumina powder, aluminum phosphate, and phosphoric acid with a mass fraction of 5% in a mass ratio of 1:2:25, add water to dilute it by 2 times, pour it into the dipping tank, and immerse the wooden skeleton in the dipping tank for 20 minutes. Then take it out and dry it with hot air at 100°C for 15 minutes.

[0055] Stir and mix the ammonium polyphosphate with a mass ratio of 1:3 and water evenly, and then pour it into another dipping tank. Immerse the above-mentioned hot-air-dried wooden skeleton in the dipping tank for 30 minutes, then take it out, and dry it with hot air at 100°C ...

Embodiment 3

[0065] The preparation method of the wooden fireproof door of the present embodiment comprises the steps:

[0066] 1) Use pine blanks to prepare a wooden skeleton. The wooden skeleton is a "mesh"-shaped frame, including two longitudinal beams and four cross beams. Evenly spaced in the extension direction. The length of the wooden skeleton is 225cm and the width is 91cm.

[0067] 2) Mix and stir alumina powder, aluminum phosphate, and phosphoric acid with a mass fraction of 5% in a mass ratio of 1:2:15, then add water to dilute it by 3 times and pour it into the dipping tank, and immerse the wooden skeleton in the dipping tank for 10 minutes. Then take it out and dry it with hot air at 120°C for 8 minutes.

[0068] Stir and mix the ammonium polyphosphate and water with a mass ratio of 1:2, and then inject it into another dipping tank. Immerse the above-mentioned hot-air-dried wooden skeleton in the dipping tank for 20 minutes, then take it out, and dry it with hot air at 80°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com