A kind of nanometer gold micelle catalyst and its preparation method and application

A nano-gold and catalyst technology, applied in the field of nano-gold micelle catalyst and its preparation, can solve the problem of lack of efficient catalysts for fatty acid esters, and achieve the effects of good catalytic oxidation performance, high ester yield and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1. Preparation method of nano-gold micelle catalyst.

[0024] (1) HAuCl 4 Aqueous solution (20mL, 0.79mg, 2.0mmol) and mPEG-SH aqueous solution (20mL, 0.56g, 4.8mmol) were mixed, and stirred at 800rpm for 40min at 25°C to obtain a mixed solution;

[0025] (2) To the mixed solution obtained in step (1), add NaBH dropwise 4 Aqueous solution (100mM, 0.4mL) was added dropwise while stirring, and reacted for 18h to obtain a wine red mPEGylated Au-NPs solution;

[0026] (3) The mPEGylated Au-NPs solution obtained in step (2) was centrifuged at 8000 r / min for 30 min to remove any unbound thiol, and the obtained supernatant was the nano-gold micelle catalyst.

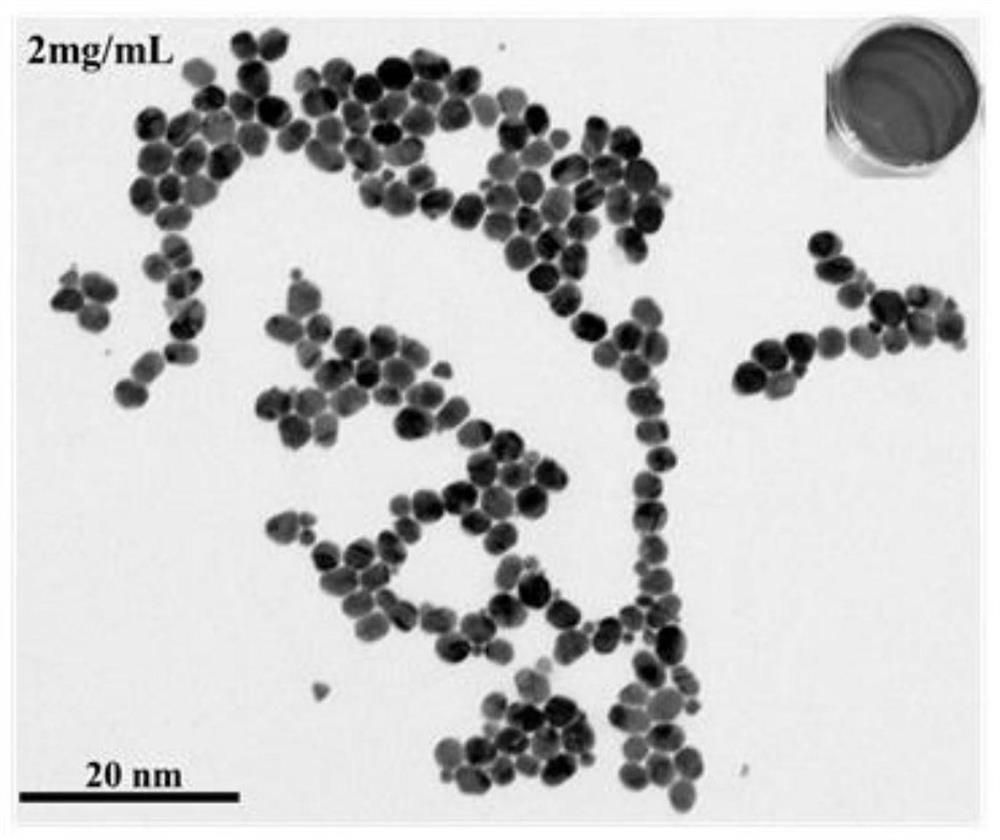

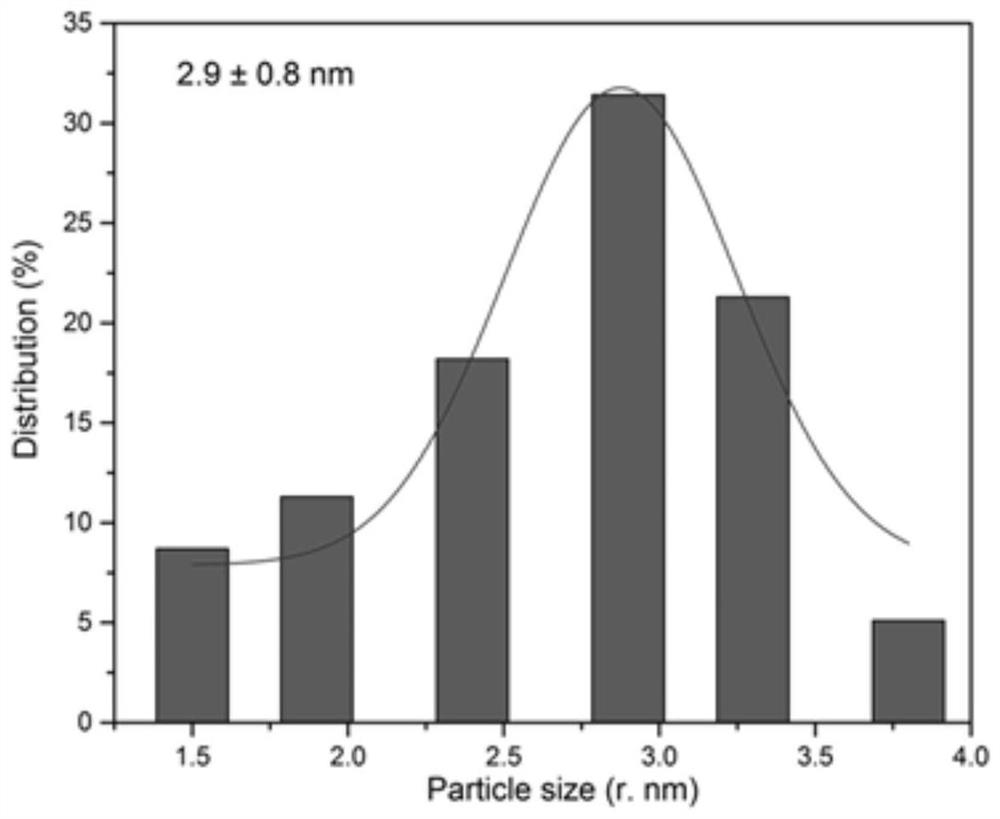

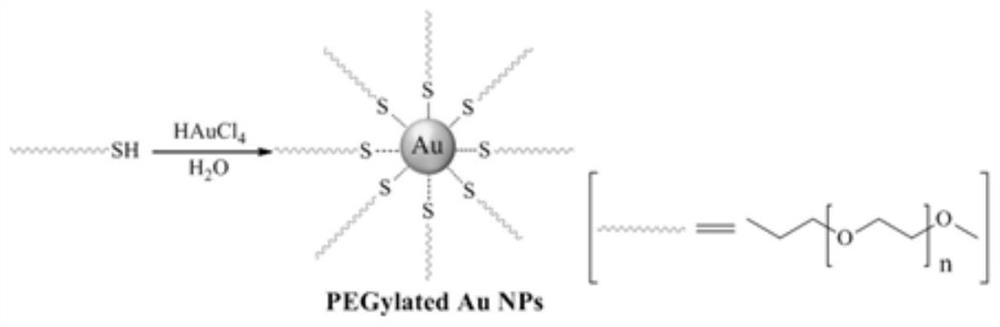

[0027] The schematic diagram of the synthesis of mPEGylated Au-NPs is shown in Fig. image 3 shown. The mPEGylated Au-NPs prepared in Example 1 was subjected to a SEM scanning test, and the test results were as follows figure 1 shown. Depend on figure 1 It can be seen that the catalyst has uniform micellar...

Embodiment 2

[0029] Example 2. Preparation method of nano-gold micelle catalyst.

[0030] (1) HAuCl 4 Aqueous solution (20mL, 0.40mg, 1.0mmol) and mPEG-SH aqueous solution (20mL, 0.23g, 2.0mmol) were mixed, and stirred at 1000rpm for 50min at 30°C to obtain a mixed solution;

[0031] (2) To the mixed solution obtained in step (1), add NaBH dropwise 4 Aqueous solution (200mM, 0.4mL) was added dropwise while stirring, and reacted for 12h to obtain a wine red mPEGylated Au-NPs solution;

[0032] (3) The mPEGylated Au-NPs solution obtained in step (2) was centrifuged at 10,000 r / min for 40 min to remove any unbound thiol, and the obtained supernatant was the nano-gold micelle catalyst.

Embodiment 3

[0033] Example 3. Preparation method of nano-gold micelle catalyst.

[0034] (1) HAuCl 4 Aqueous solution (20mL, 3.95mg, 10.0mmol) and mPEG-SH aqueous solution (20mL, 1.15g, 10.0mmol) were mixed, and stirred at 500rpm for 30min at 20°C to obtain a mixed solution;

[0035] (2) To the mixed solution obtained in step (1), add NaBH dropwise 4 Aqueous solution (300mM, 0.4mL) was added dropwise while stirring, and reacted for 24h to obtain a wine red mPEGylated Au-NPs solution;

[0036] (3) The mPEGylated Au-NPs solution obtained in step (2) was centrifuged at 12000 r / min for 60 min to remove any unbound thiol, and the obtained supernatant was the nano-gold micelle catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com