Manufacturing method of back contact heterojunction solar cell with double-sided power generation

A technology of a solar cell and a manufacturing method, which is applied in the field of solar cells, can solve the problems of power generation without any advantage and can only generate electricity from one side, and achieves the effects of increasing the power generation of modules, improving quality and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

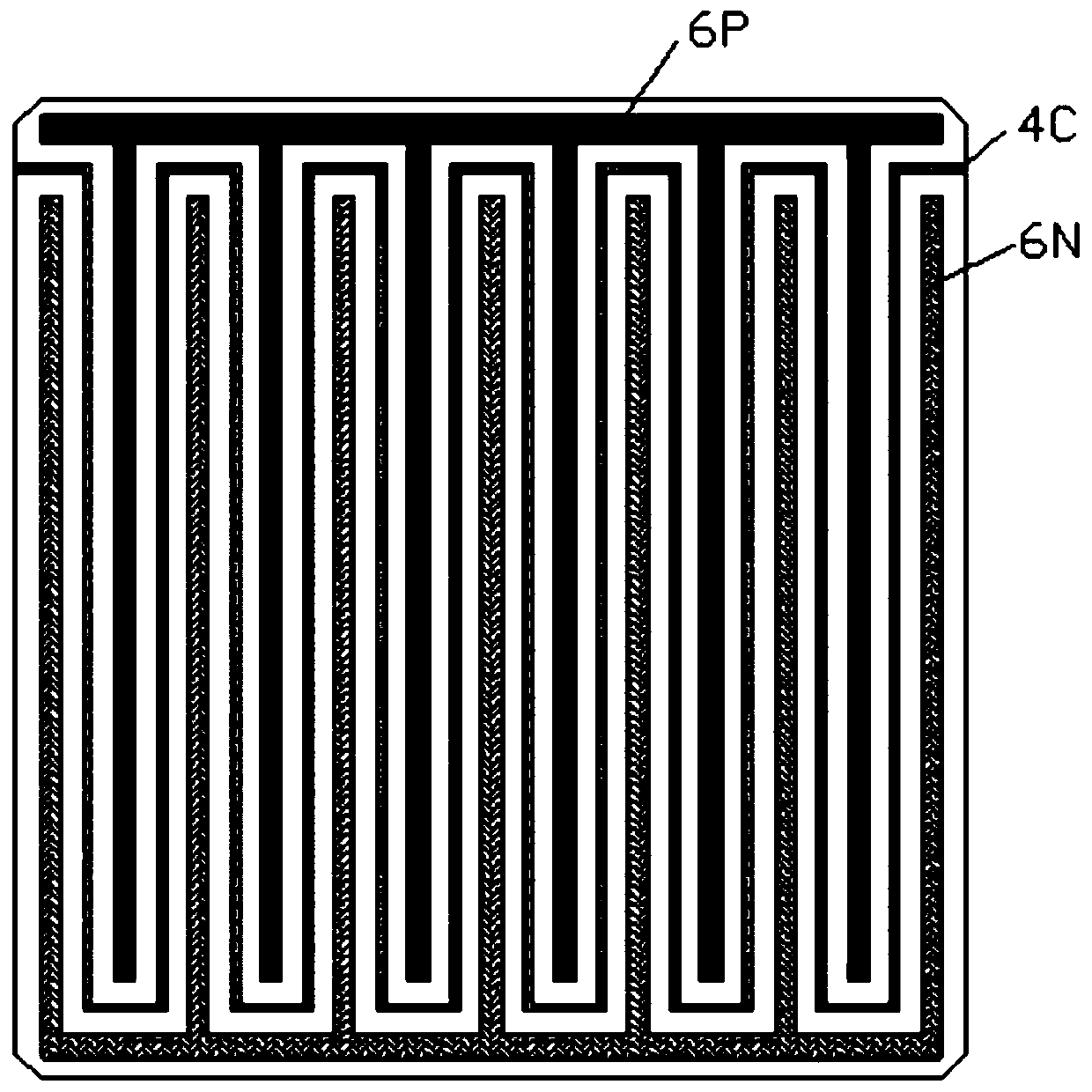

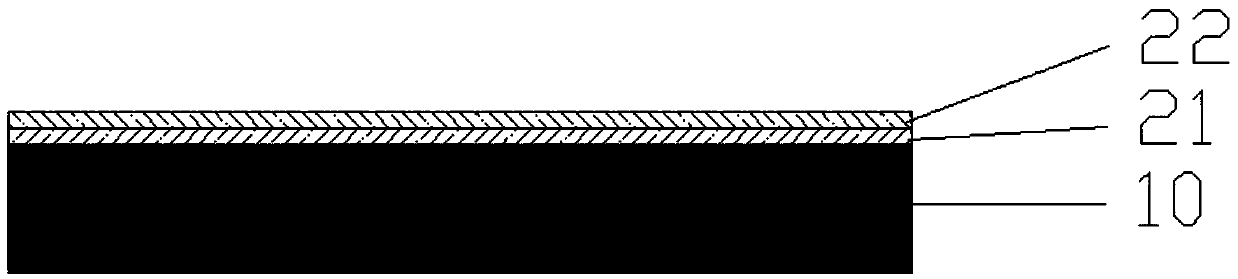

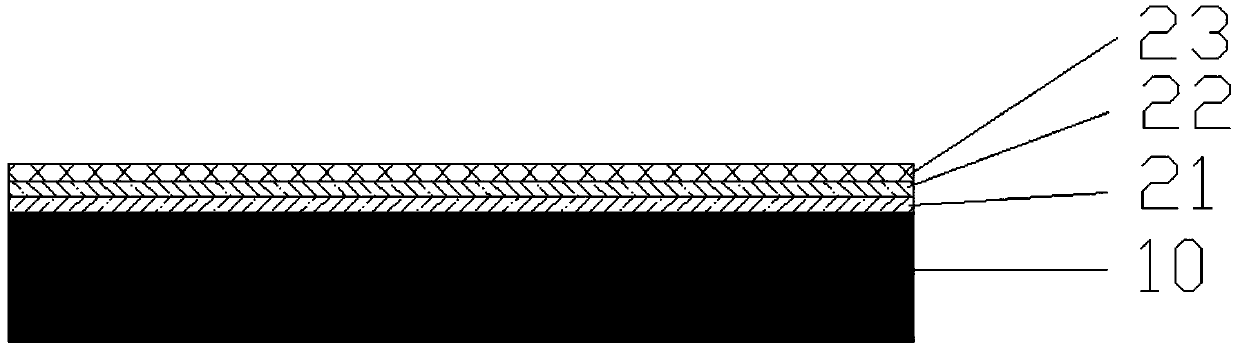

[0040] Such as figure 2 As shown, an N-type silicon wafer 10 that is textured and cleaned to form a textured surface is provided; a first intrinsic amorphous silicon layer 21 and an N-type amorphous silicon layer 22 are sequentially plated on the back side of the silicon wafer 10 to form a first semiconductor layer, The thickness of the first intrinsic amorphous silicon layer 21 and the N-type amorphous silicon layer 22 is 7nm, and the amorphous silicon film layer is deposited and formed by PECVD; as image 3 As shown, an insulating layer 23 is coated on the back side of the silicon wafer 10. The insulating layer 23 is silicon nitride with a thickness of 800nm. The insulating layer 23 is formed by PECVD deposition; Figure 4As shown, the insulating layer 23, the N-type amorphous silicon layer 22, and the first intrinsic amorphous silicon layer 21 in the corresponding area are etched and removed by printing etching paste on the local area of the back side of the silicon wafe...

Embodiment 2

[0042] The difference from Example 1 is that, as Figure 13 As shown, the formation of the negative electrode lead-out groove 2N adopts the method of wet etching after printing the protective ink 3B on the back side of the silicon wafer 10. The protective ink 3B is an acid-resistant and not alkali-resistant ink. The curing temperature of the ink is 120°C, and the curing time is 10M. The wet etching solution is an HF solution containing a metal catalyst, and the protective ink 3B is removed by alkaline solution.

Embodiment 3

[0044] The difference from Example 1 is that, as Figure 14 As shown, the insulating groove 4C is formed by printing the protective ink 4B on the back side of the silicon wafer and then wet etching. The protective ink 4B is an acid-resistant and not alkali-resistant ink. The curing temperature of the ink is 120°C and the curing time is 10M. The wet etching solution is a mixed solution of hydrochloric acid and hydrogen peroxide, the etching time is 1 minute, and the protective ink 4B is removed by alkaline solution.

[0045] The present invention adopts the above-mentioned technical scheme, aiming at the characteristics of heterojunction thermal attenuation, the fabrication of the second semiconductor (i.e., the hole collector) occurs after the first semiconductor (i.e., the electron collector), so as to ensure that the thin film produced before has a higher High thermal stability and better quality, improve the quality of the produced products; by forming the insulating groove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com