Pine needle-shaped nickel-cobalt-copper basic carbonate nano composite material as well as preparation method and application thereof

A nanocomposite material, carbonate technology, applied in nanotechnology, nanotechnology, hybrid/electric double layer capacitor manufacturing and other directions, can solve problems such as poor conductivity, structural instability, etc. The effect of high charge transfer rate and charge transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

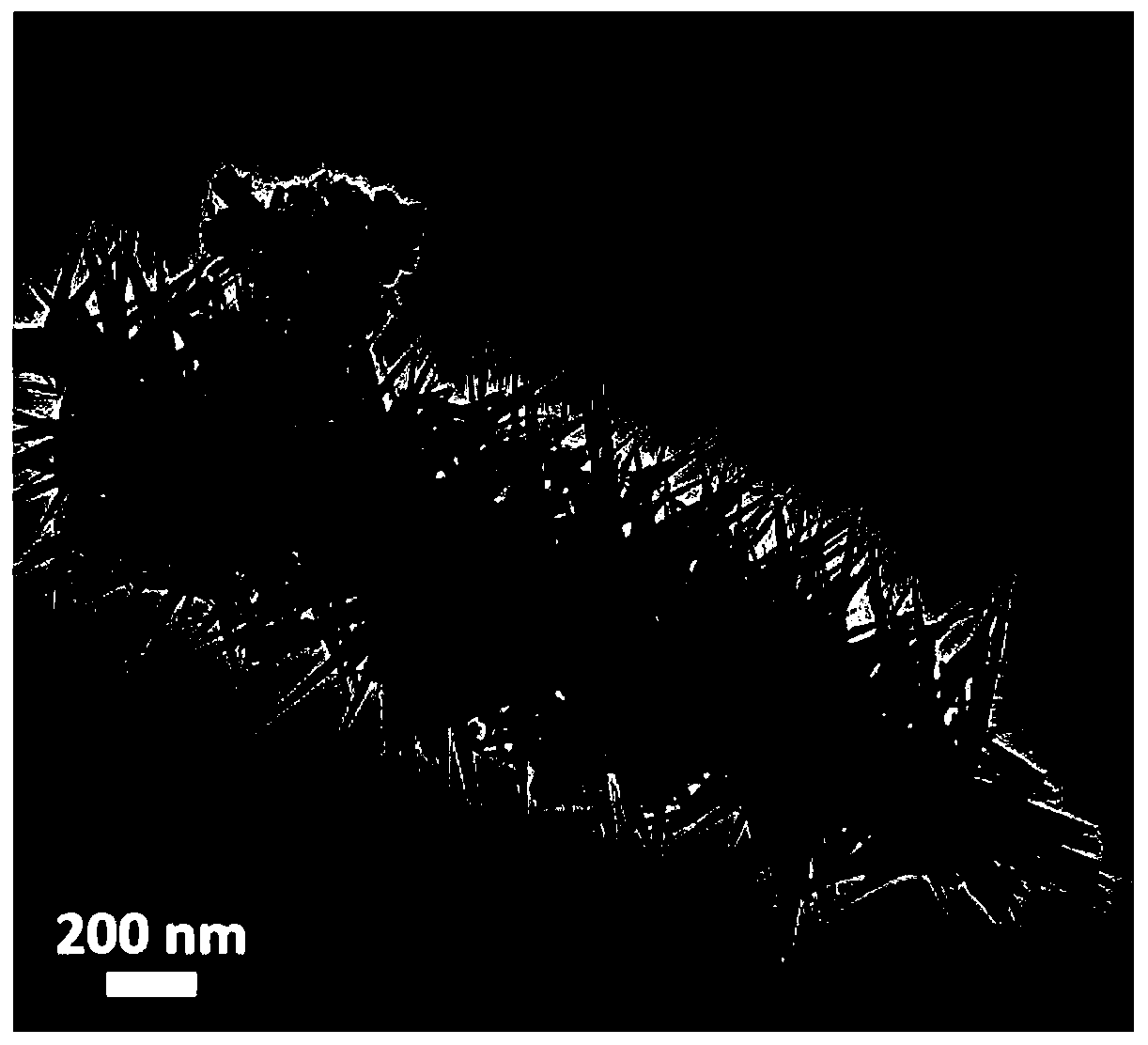

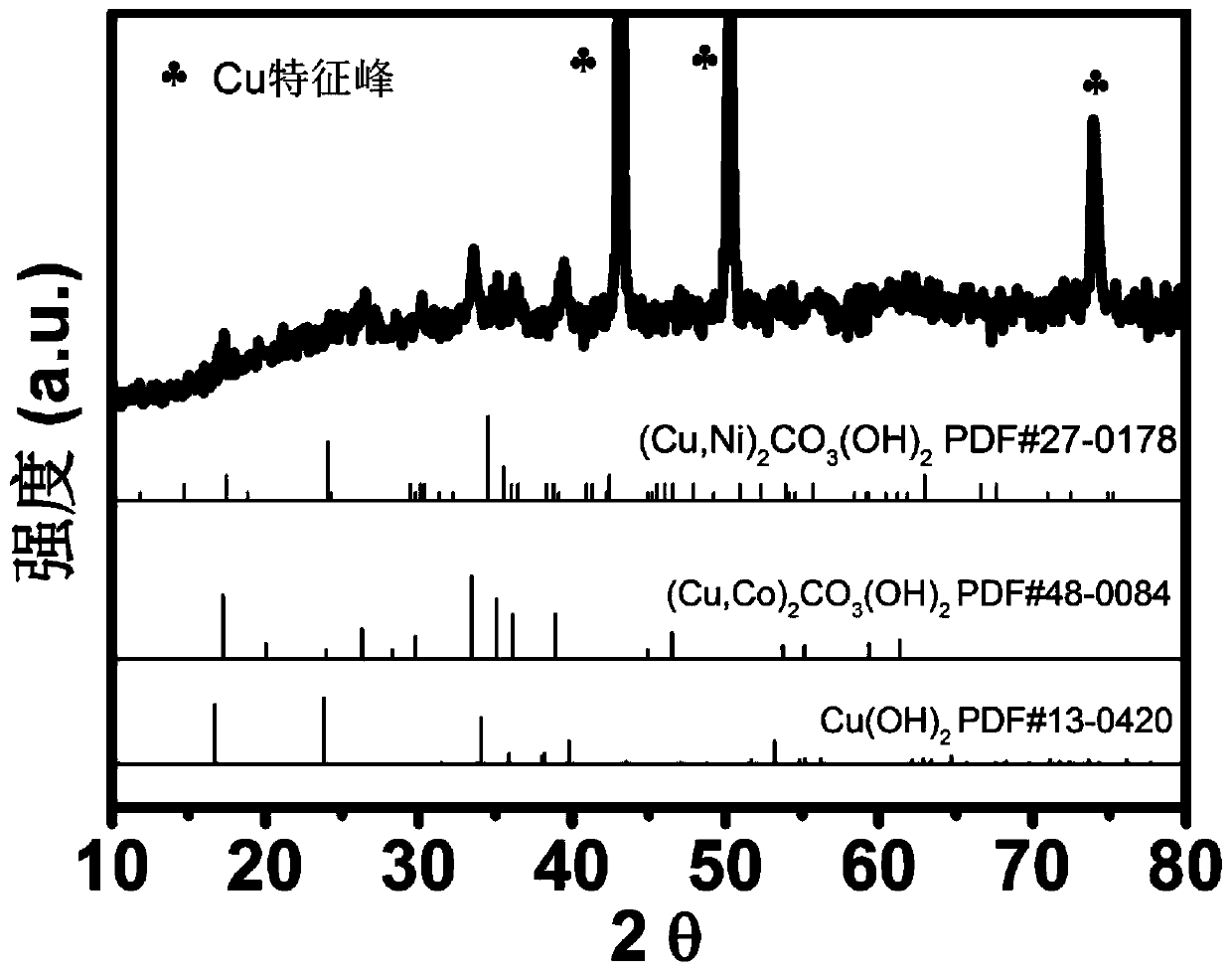

[0039] A preparation method of pine needle-shaped nickel-cobalt-copper basic carbonate nanocomposite material activated by cyclic voltammetry, specifically comprising the following steps:

[0040] 1) Dissolve 1.8g of ammonium persulfate and 2.4g of sodium hydroxide in 40ml of deionized water and stir continuously for 20 minutes to form a uniform transparent mixed alkaline etching solution with a surface area of 4cm 2 , soak copper foam with a thickness of 1mm in the above mixture, chemically etch at 25°C for 20 minutes, wash with deionized water three times, and dry at 80°C to obtain foamed copper sheets with copper hydroxide nanorods grown;

[0041] 2) 0.58g cobalt nitrate, 0.29g nickel nitrate, 0.9g urea and 0.46g ammonium acetate were dissolved in deionized water, and stirred continuously for 20 minutes to form a uniform transparent mixed solution, and the grown copper hydroxide nanorod obtained in 1) was The foamed copper sheet was placed in the solution under hydrotherm...

Embodiment 2

[0057] A preparation method of pine needle-shaped nickel-cobalt-copper basic carbonate nanocomposite material activated by cyclic voltammetry, specifically comprising the following steps:

[0058] 1) Dissolve 1.8g of ammonium persulfate and 1.5g of sodium hydroxide in 40ml of deionized water and stir continuously for 20 minutes to form a uniform transparent mixed alkaline etching solution with a surface area of 4cm 2 , soak copper foam with a thickness of 3mm in the above mixed solution, chemically etch at 25°C for 5 minutes, wash with deionized water three times, and dry at 80°C to obtain foamed copper sheets with copper hydroxide nanorods grown;

[0059] 2) Dissolve 0.58g of cobalt nitrate, 0.29g of nickel nitrate, 1.8g of urea and 0.46g of ammonium acetate in deionized water, and stir continuously for 20 minutes to form a uniform transparent mixed solution. The grown copper hydroxide obtained by chemical etching in 1) The foamed copper sheets of nanorods were placed in th...

Embodiment 3

[0064] A preparation method of pine needle-shaped nickel-cobalt-copper basic carbonate nanocomposite material activated by cyclic voltammetry, specifically comprising the following steps:

[0065] 1) Dissolve 1.8g of ammonium persulfate and 2.8g of sodium hydroxide in 40ml of deionized water and stir continuously for 20 minutes to form a uniform transparent mixed alkaline etching solution with a surface area of 4cm 2 , foamed copper with a thickness of 1mm is immersed in the above mixture, chemically etched at 25°C for 10 minutes, washed with deionized water three times, and dried at 80°C to obtain foamed copper sheets with copper hydroxide nanorods grown;

[0066]2) Dissolve 0.29g cobalt nitrate, 0.58g nickel nitrate, 0.9g urea and 0.46g ammonium acetate in deionized water, stir continuously for 20 minutes to form a uniform and transparent mixed solution, and chemically etch the grown copper hydroxide obtained in 1) The foamed copper sheets of the nanorods are placed in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com