Zirconium-free mutton fat glaze and positioning crystal pattern ceramic tile prepared from the same

A technology of zirconium suet and ceramic tiles, applied in the field of zirconium-free suet glaze, can solve the problems such as the decline of the whitening effect, and achieve the effect of improving the texture and grade, and the texture is delicate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

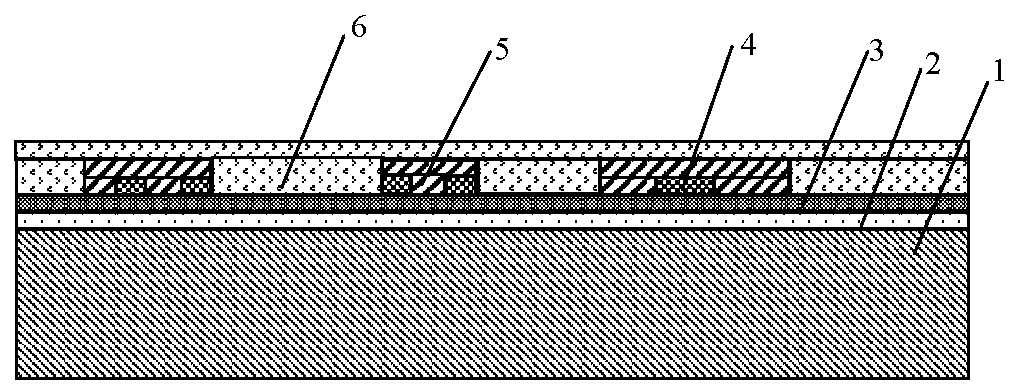

Method used

Image

Examples

Embodiment 1

[0071]Step 1: Press the adobe. The green body is obtained by pressing the ceramic base material commonly used in the field.

[0072] Step 2: Dry the green body, the drying time is 60 minutes, and the moisture content of the dried green body is controlled within 0.5%.

[0073] Step 3: Spray zirconium-free suet glaze on the dried brick by spraying glaze. The mineral composition of zirconium-free suet glaze is: 50% washed ultra-white potassium feldspar, 20% washed ultra-white albite, washed Ultra white kaolin 25%, calcined alumina 5%. The chemical composition of zirconium-free suet glaze is: SiO 2 : 60.92%, Al 2 o 3 : 26.08%, Fe 2 o 3 : 0.11%, TiO 2 : 0.01%, CaO: 0.21%, MgO: 0.09%, K 2 O: 5.03%, Na 2 O: 3.59%, loss on ignition: 3.96%. The specific gravity of the glaze is 1.45, and the amount of glaze is 480g / m 2 .

[0074] Step 4: Print the inkjet design pattern with a digital inkjet machine.

[0075] Step 5: Print the colored primer glaze with a roller engraved with...

Embodiment 2

[0085] The difference from Example 1 is that the mineral composition of zirconium-free suet glaze is: 55% washed ultra-white potassium feldspar, 15% washed ultra-white albite, 27% washed ultra-white kaolin, and 3% calcined alumina . The chemical composition of zirconium-free suet glaze is: SiO 2 : 61.92%, Al 2 o 3 : 24.72%, Fe 2 o 3 : 0.11%, TiO 2 : 0.01%, CaO: 0.23%, MgO: 0.07%, K 2 O: 5.50%, Na 2 O: 3.28%, loss on ignition: 4.14%.

[0086] Figure 4 The photo of the brick surface of the ceramic brick prepared in Example 2 shows that the brick surface not only has brightly colored stone texture patterns, but also has some white fixed-point positioning three-dimensional crystal flower effect pattern layers, and the white crystal flower pattern There are also colored crystal flowers in it.

[0087] Use the test method in GB / T 3810.7-2016 "Determination of Abrasion Resistance of Glazed Tile Surface" to test the abrasion resistance of the glazed surface, and use the tes...

Embodiment 3

[0090] The difference from Example 1 is that the mineral composition of the zirconium-free suet glaze is: 45% washed ultra-white potassium feldspar, 25% washed ultra-white albite, 23% washed ultra-white kaolin, and 7% calcined alumina . The chemical composition of zirconium-free suet glaze is: SiO 2 : 59.91%, Al 2 o 3 : 27.44%, Fe 2 o 3 : 0.11%, TiO 2 : 0.01%, CaO: 0.18%, MgO: 0.1%, K 2 O: 4.57%, Na 2 O: 3.89%, loss on ignition: 3.77%.

[0091] Figure 5 The photo of the brick surface of the ceramic brick made in Example 3 shows that the brick surface not only has a brightly colored stone texture pattern, but also has some white fixed-point positioning three-dimensional crystal flower effect pattern layers, and the white crystal flower pattern There are also colored crystal flowers in it.

[0092] Use the test method in GB / T 3810.7-2016 "Determination of Abrasion Resistance of Glazed Tile Surface" to test the abrasion resistance of the glazed surface, and use the tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com