Cross-flow belt type sludge dryer

A sludge belt type, dryer technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of low thermal efficiency, unfavorable sludge heat absorption, unreasonable air supply of the dryer, etc. The effect of smooth material and unblocked material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

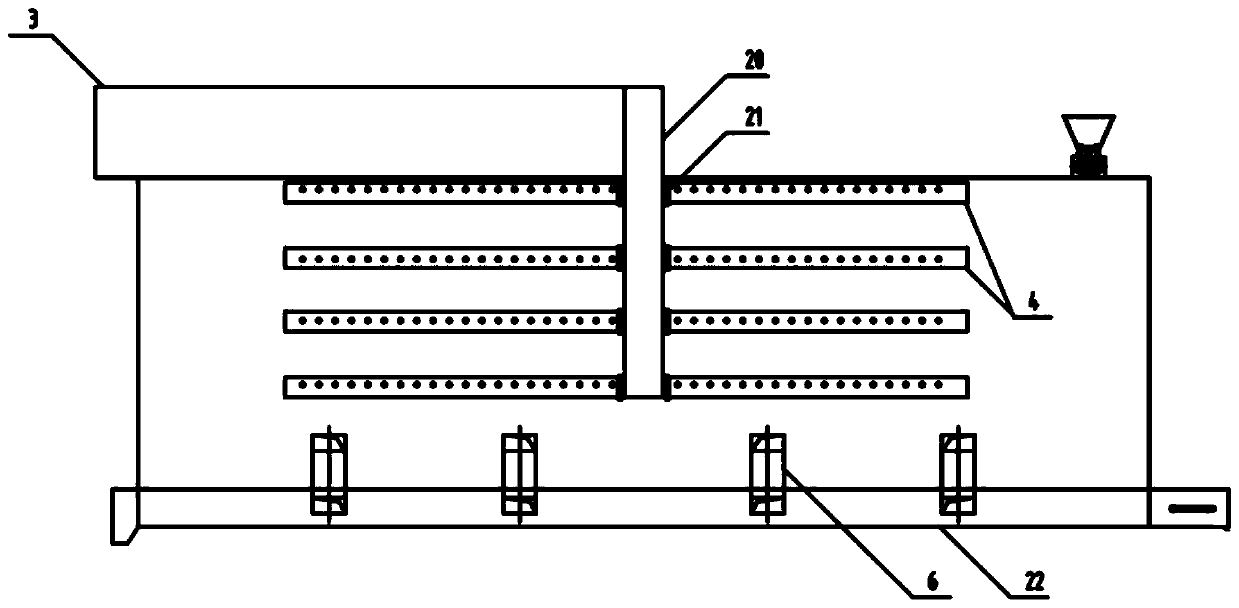

[0026] The illustrated legend is a schematic diagram of an embodiment of the through-flow sludge belt dryer of the present invention, which is used in the sludge treatment industry. The present invention provides a semi-dry dryer with a moisture content of 68-72%. The sludge is dried to a dry sludge with a moisture content of 10-20%, and the heat of the incinerated and dried sludge can meet the heat required by the dryer. It is a belt dryer with high thermal efficiency.

[0027] Such as Figure 1-3 A through-flow sludge belt dryer is shown. The through-flow sludge belt dryer includes a box-type body 1, and there are several drying layers 2 arranged in parallel in the box-type body from top to bottom. , The drying layer 2 is a metal mesh conveyor belt, and the mesh belts of each drying layer 2 run in opposite directions, and the materials are transferred from the upper drying layer to the lower drying layer sequentially by gravity. The drying air enters the air inlet channel 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com