Welding method for relieving residual stress of ceramic and metal brazed joint

A technology of metal brazing and residual stress, which is applied in the direction of welding/welding/cutting articles, welding equipment, metal processing equipment, etc., can solve the problems of poor reliability, large residual stress, and low mechanical properties, so as to reduce the coefficient of thermal expansion, The effect of large modulus of elasticity and low coefficient of thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

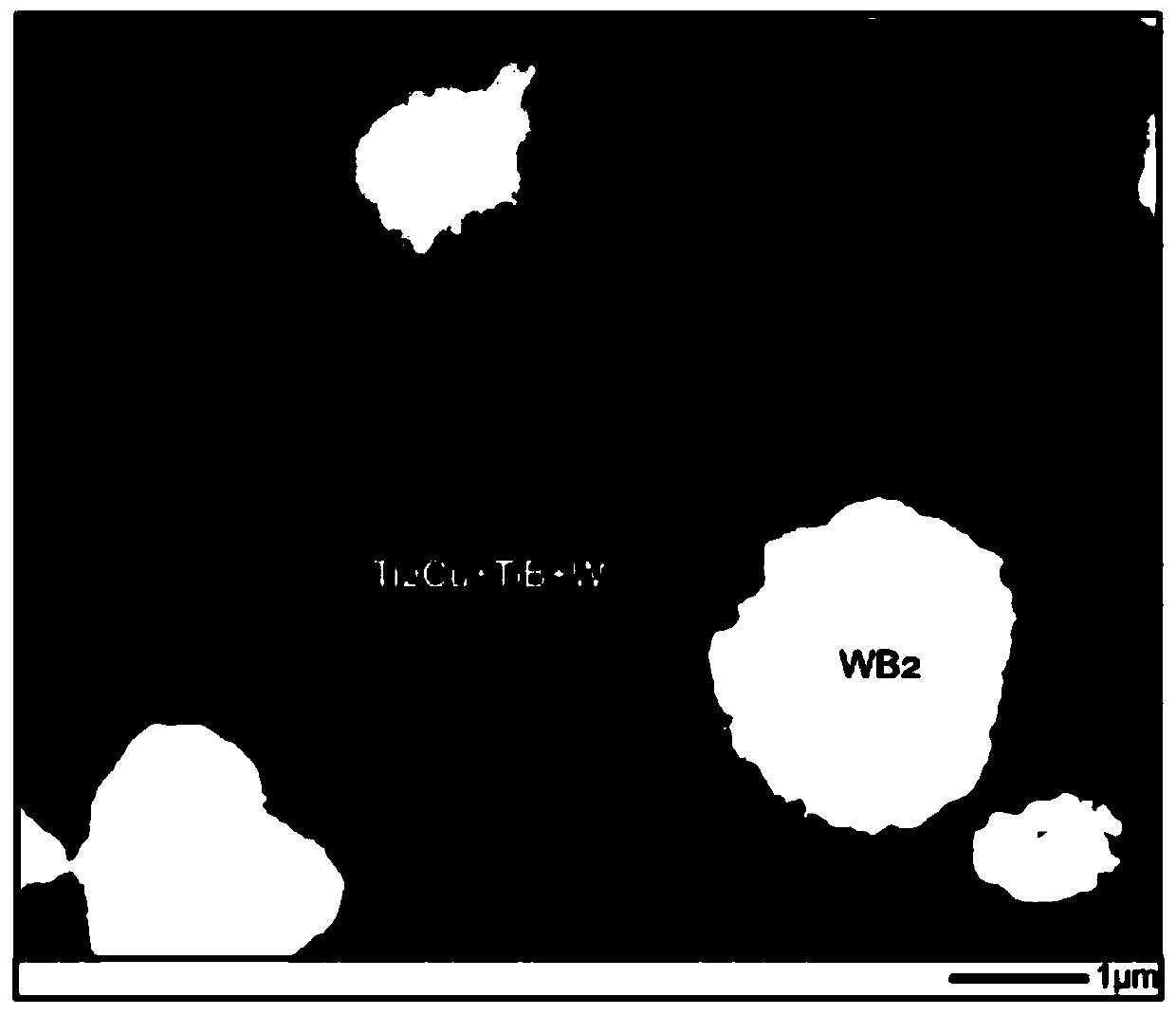

Method used

Image

Examples

Embodiment 1

[0087] This embodiment provides a welding method for alleviating the residual stress of ceramic and metal brazing joints, which specifically includes:

[0088] S1, select Al 2 o 3 For ceramics, first use 800#~2000# diamond sand discs to Al 2 o 3 The surface to be connected of the ceramics is polished, and secondly, the surface to be connected is polished with 1000#~7000# SiC water sandpaper in sequence, and then mechanically polished until the surface to be connected is a mirror surface, and the Al 2 o 3 Surface to be joined of ceramics.

[0089] Select titanium-based material Ti-6Al-4V, use 1000#~7000# water sandpaper to polish the surface to be connected of Ti-6Al-4V in sequence, and then perform mechanical polishing until the surface to be connected is a mirror surface, to obtain Ti-6Al Modified surface of -4V.

[0090] The polished ZrC-SiC ceramics and Ti-6Al-4V were ultrasonically cleaned 4 times with acetone, each time for 10 minutes, and then dried to obtain the Z...

Embodiment 2

[0099] The difference between this embodiment 2 and embodiment 1 is that this embodiment uses Al 2 o 3 Ceramics and Ti-6Al-4V are directly brazed, and no surface modification layer is set on the titanium-based material Ti-6Al-4V.

[0100] In the specific preparation process, the main difference between embodiment 2 and embodiment 1 is that embodiment 2 does not include steps S2 and step S3 described in embodiment 1, and in the brazing process of step S4, it is in direct contact with the solder Al 2 o 3 Ceramic surface to be connected and Ti-6Al-4V surface to be connected.

[0101] Comparing Example 1 and Example 2, using the brazing joint 1 obtained by the welding method described in Example 1 to relieve the residual stress of ceramic and metal brazing joints, the joint 1 has a shear strength of 242MPa. However, for the brazed joint 2 obtained by the direct brazing method described in Comparative Example 2, the measured shear strength of the brazed joint 2 is only 60 MPa. ...

Embodiment 3

[0104] This embodiment provides a welding method for alleviating the residual stress of ceramic and metal brazing joints, which specifically includes:

[0105] S1. Select ZrC-SiC ceramics. First, use 800#~2000# diamond sand discs to polish the surface to be connected of ZrC-SiC ceramics. Secondly, use 1000#~7000# SiC water sandpaper to polish the surface to be connected. Afterwards, mechanical polishing is carried out until the surface to be connected is a mirror surface, and the surface to be connected of ZrC-SiC ceramics is obtained.

[0106] Select titanium-based material Ti-6Al-4V, use 1000#~7000# water sandpaper to polish the surface to be connected of Ti-6Al-4V in sequence, and then perform mechanical polishing until the surface to be connected is a mirror surface, to obtain Ti-6Al Modified surface of -4V.

[0107] The polished ZrC-SiC ceramics and Ti-6Al-4V were ultrasonically cleaned 4 times with acetone, each time for 10 minutes, and then dried to obtain the ZrC-SiC ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com