Rapid calculation method for PWM harmonic loss of permanent magnet motor

A permanent magnet motor and harmonic loss technology, which is applied in the control of generators, motor generators, electronically commutated motors, etc., can solve time-consuming problems and achieve the effect of increasing calculation speed and shortening calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0048] This embodiment takes the embedded permanent magnet synchronous motor applied in Prius2010 as an example for calculation.

[0049] The method for quickly calculating the PWM harmonic iron loss in its silicon steel sheet includes the following specific steps:

[0050] Step 1, with i d0 =-64.9A, i q0 =76.04A is the input, and the rotor electrical angle θ e From 0 to 360° static finite element calculation, the magnetic density of each mesh is obtained.

[0051] Step 2, according to the calculation results of the previous step, use the frozen tensor incremental permeability method to construct θ e A linear AC small-signal model of a permanent magnet motor at different rotor positions.

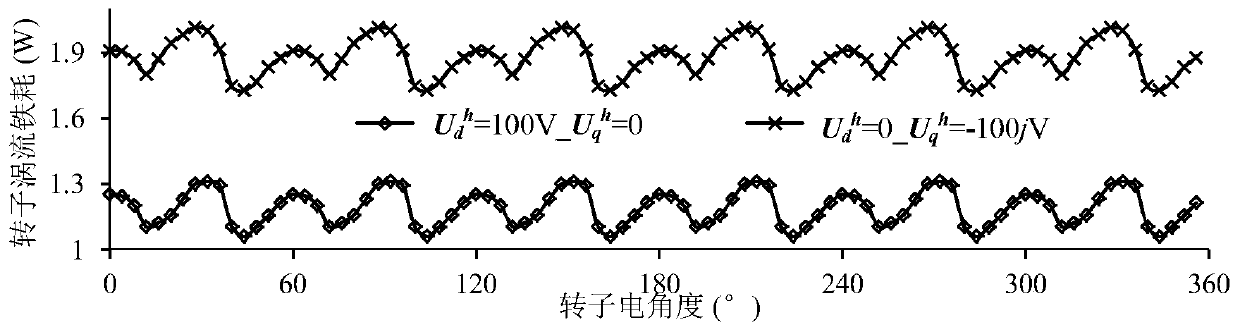

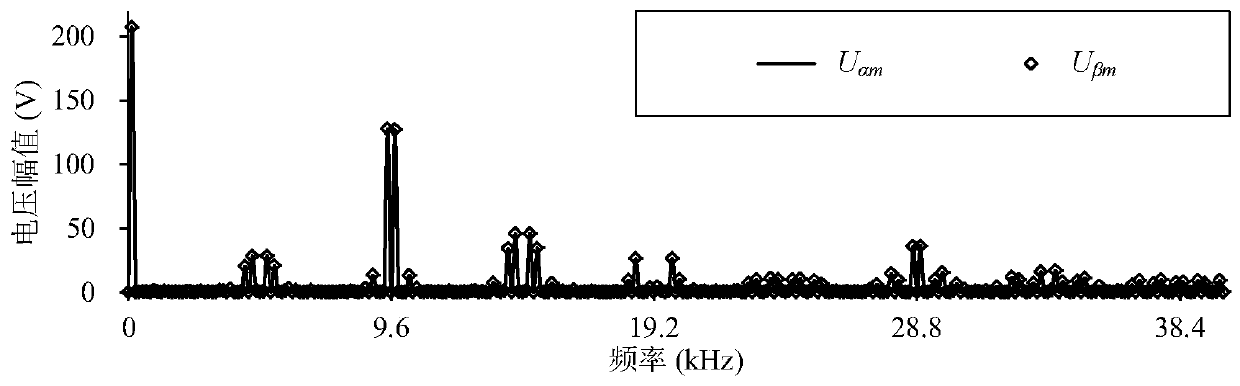

[0052] Step 3, using the constructed linear AC small-signal model of the permanent magnet motor, use the linear frequency domain finite element meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com