PTP packaging machine

A packaging machine and packaging technology, applied in packaging, transportation and packaging, packaging/bundling items, etc., can solve problems such as unclear printing content, dangerous bad conditions, scratches on the printing part, etc., to suppress the occurrence of bad tablets, Easy and simple recycling, seeking the effect of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

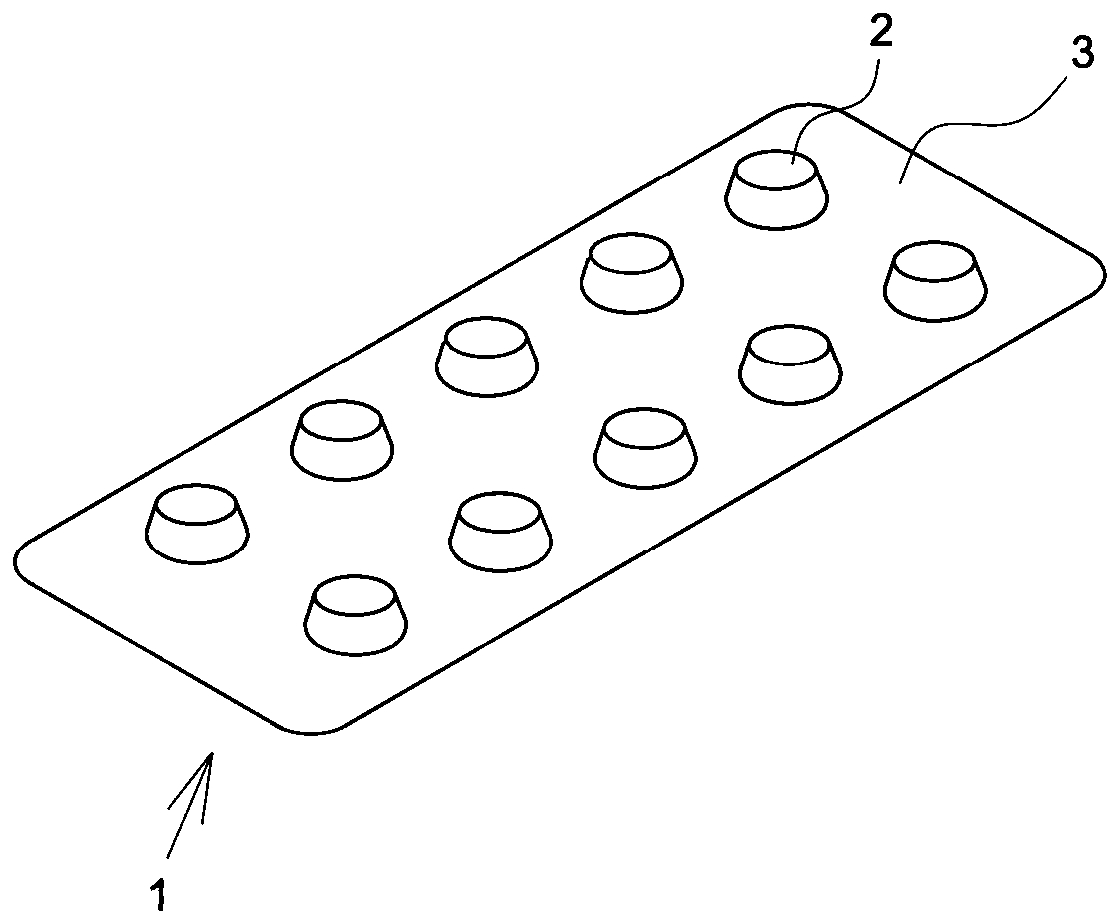

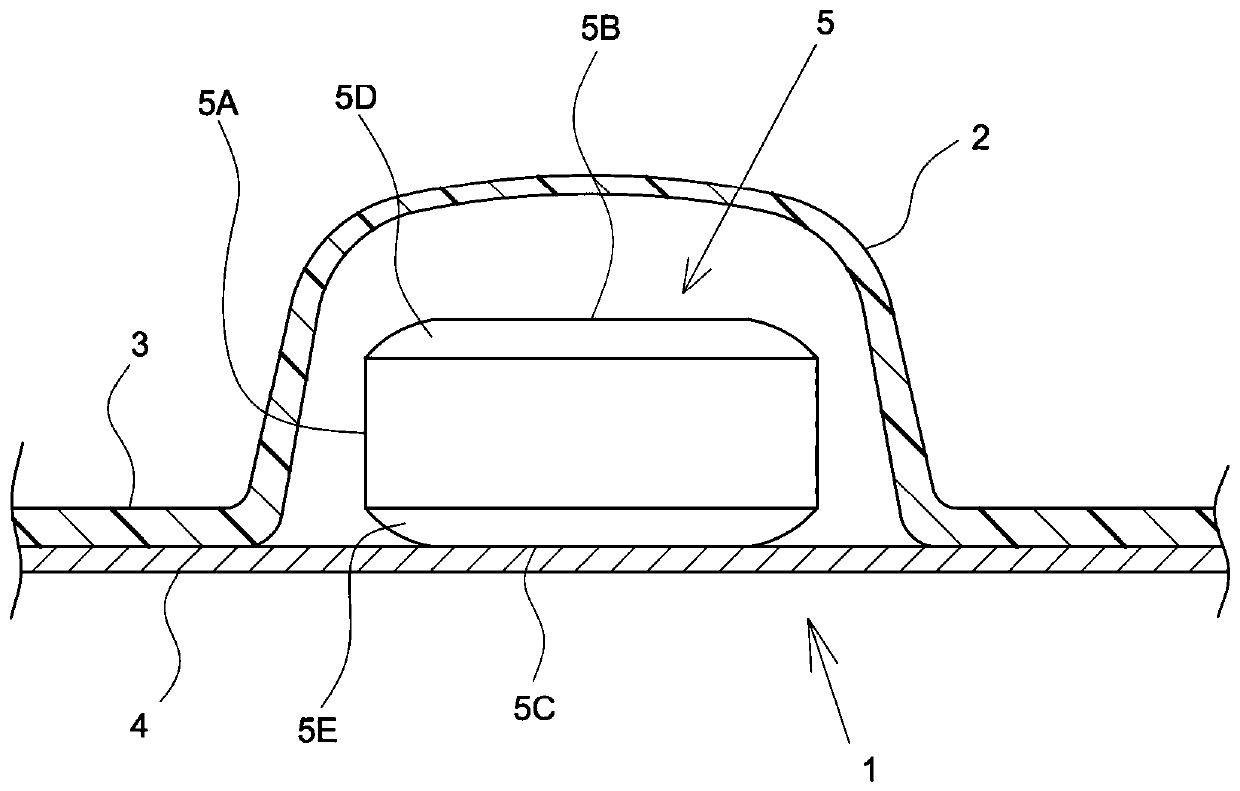

[0056] Hereinafter, one embodiment will be described with reference to the drawings. First, the structure of the PTP sheet will be specifically described.

[0057] picture figure 1 , figure 2 As shown, the PTP sheet 1 includes a container film 3 having a plurality of pockets 2 and a cover film 4 attached to the container film 3 so as to close the pockets 2 .

[0058] The container film 3 of the present embodiment is formed of a transparent thermoplastic resin material such as PP (polypropylene) and PVC (polyvinyl chloride), and has light transmittance. On the other hand, the cover film 4 is formed of an opaque material (such as aluminum foil or the like) provided on the outer surface with a sealant made of polypropylene resin or the like, for example. Obviously, the material of each film 3 and 4 is not limited to this, and other materials can also be used.

[0059] The PTP sheet 1 is produced by a tape-shaped PTP film 6 formed of a tape-shaped container film 3 and a tape-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com