A Vibration Actively Controlled Axial Piston Pump with Magnetic Bearings

An axial piston pump and active control technology, applied in the field of axial piston pumps, can solve problems such as cylinder overturning, affecting the reliability and life of axial piston pumps, reduce vibration and noise, and improve instability resistance Ability to improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further illustrated and described below through specific embodiments in conjunction with the accompanying drawings.

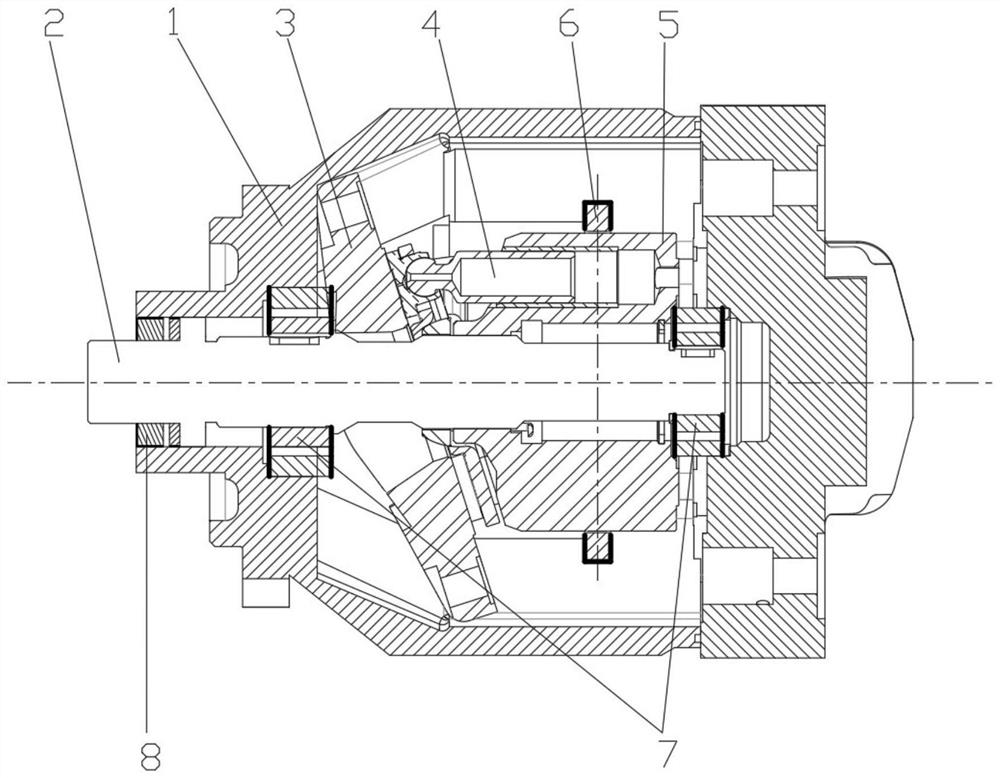

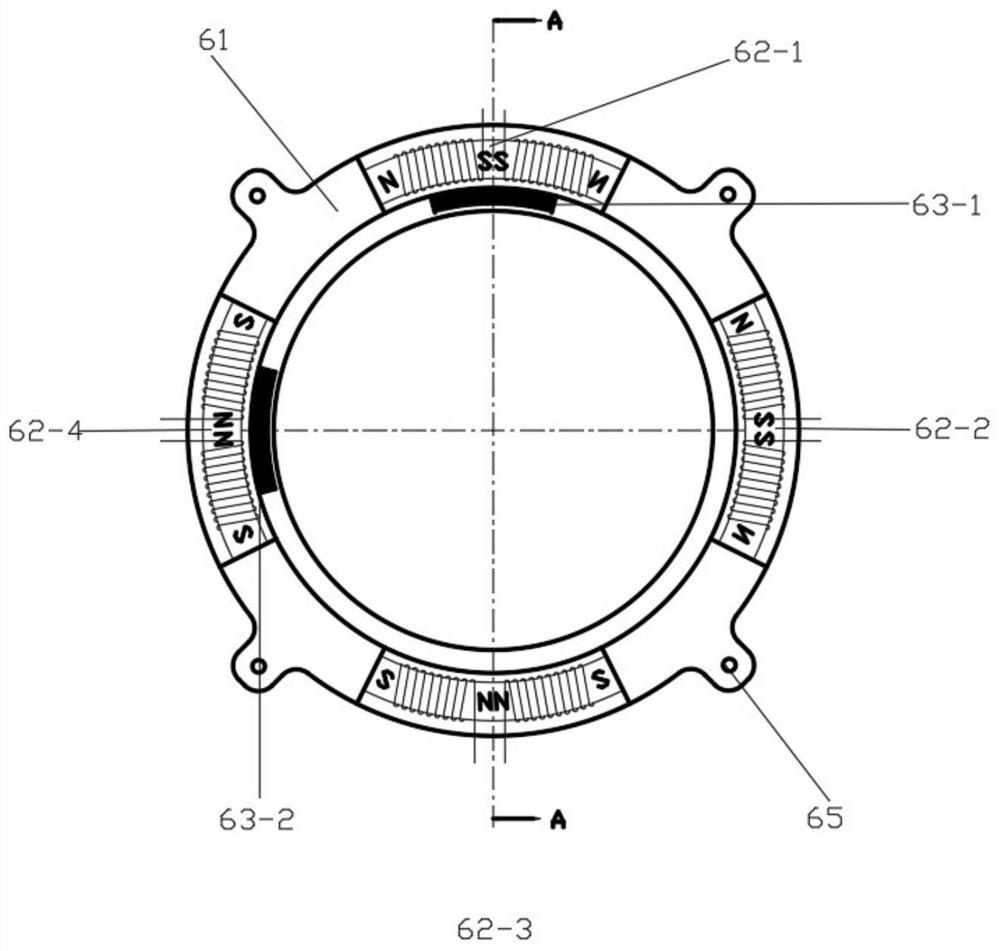

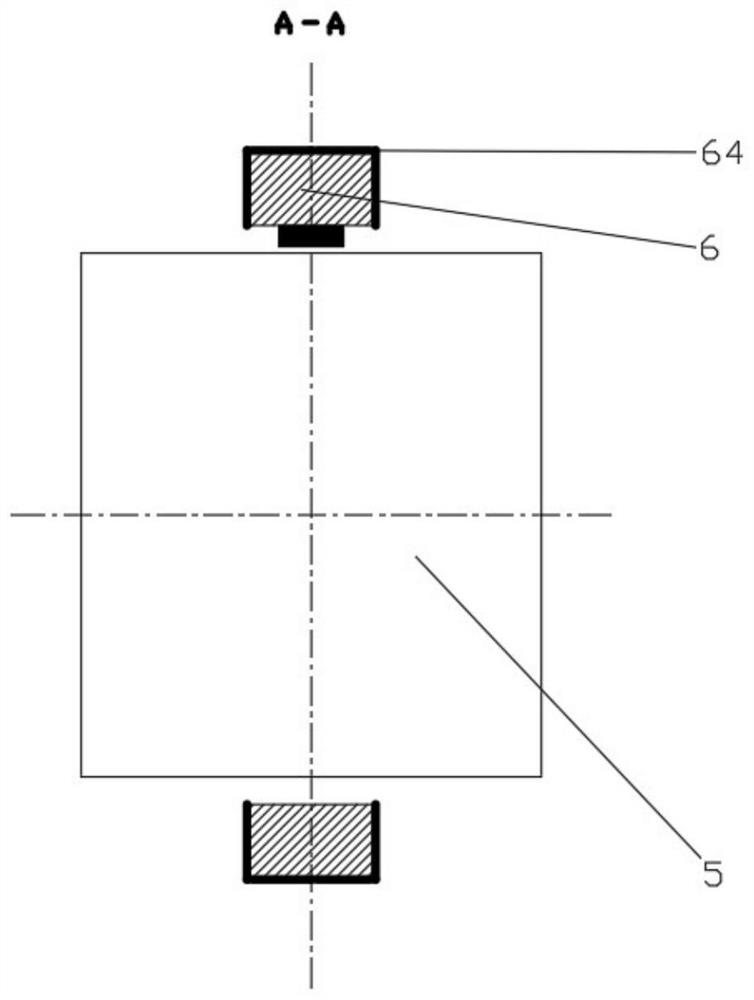

[0037] Such as figure 1 As shown, a vibration active control axial piston pump with magnetic bearing and its control method, including a housing 1, a stepped drive shaft 2, a swash plate 3, a plunger movement assembly 4, a cylinder body 5, a radial Magnetically controlled outer ring 6, first and second radial permanent magnetic bearings 7, and axially positioned magnetically controlled bearings 8. The radial magnetic control outer ring 6 is installed concentrically at the center of the cylinder body, and is connected with the housing 1 through a bolt assembly; They are connected by bolt components; the first and second radial permanent magnetic bearings 7 are installed on the left and right sides of the stepped drive shaft 2 .

[0038] The stepped drive shaft 2 passes through the swash plate 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com