Active digital printing paste composition and preparation method thereof

A technology of digital printing and composition, which is applied in dyeing, textiles and papermaking, etc. It can solve the problems of complex preparation process of modified sodium alginate, insignificant advantages of printing performance, and insufficient persuasion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

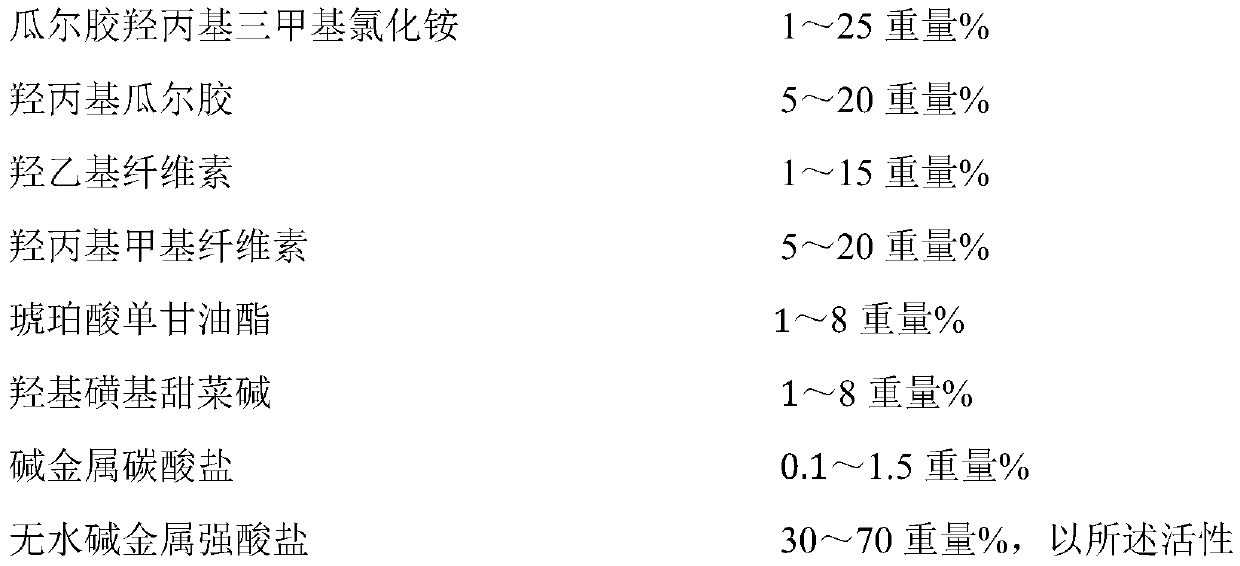

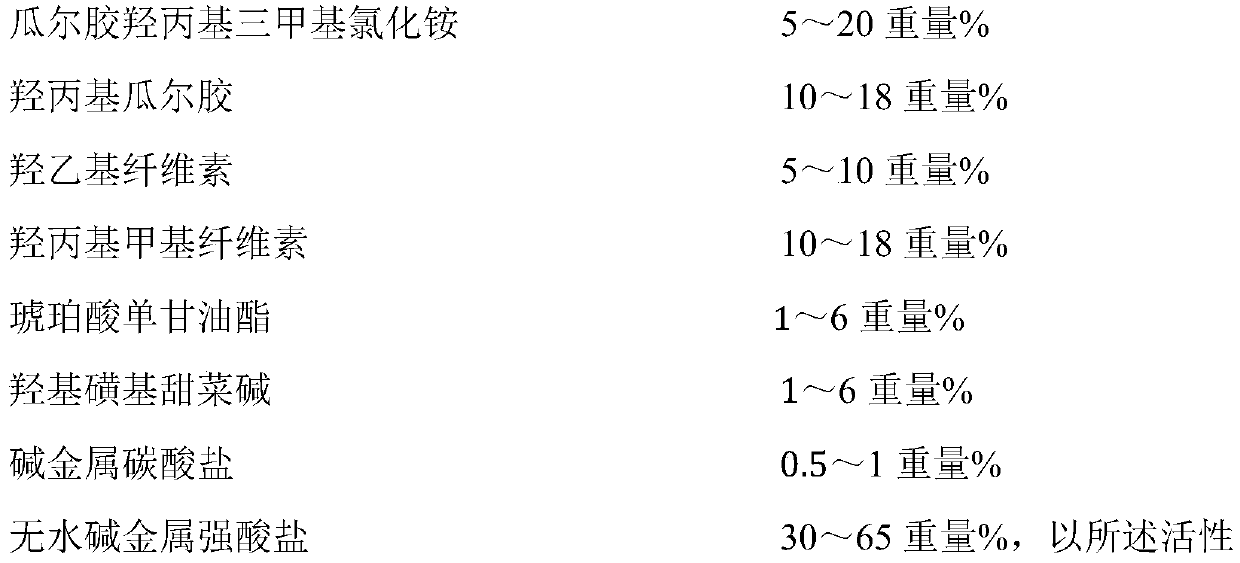

[0022] In a preferred embodiment, the preparation method of active digital printing paste composition of the present invention it comprises:

[0023] At a temperature of 15-35°C, 1-25 parts by weight of guar gum hydroxypropyltrimethylammonium chloride, 5-20 parts by weight of hydroxypropyl guar gum, and 1-15 parts by weight of hydroxyethyl cellulose Mix with 5-20 parts by weight of hydroxypropyl methylcellulose, then add 1-8 parts by weight of monoglyceride succinate, 1-8 parts by weight of anhydrous alkali metal strong acid salt and 0.1-1.5 parts by weight of alkali metal carbonate salt, and finally add 30-70 parts by weight of hydroxysultaine, and stir evenly.

[0024] In a more preferred embodiment, the preparation method of active digital printing paste composition of the present invention it comprises:

[0025] At a temperature of 20-30°C, 5 to 20 parts by weight of guar gum hydroxypropyltrimethylammonium chloride, 10 to 18 parts by weight of hydroxypropyl guar gum, and ...

Embodiment 1

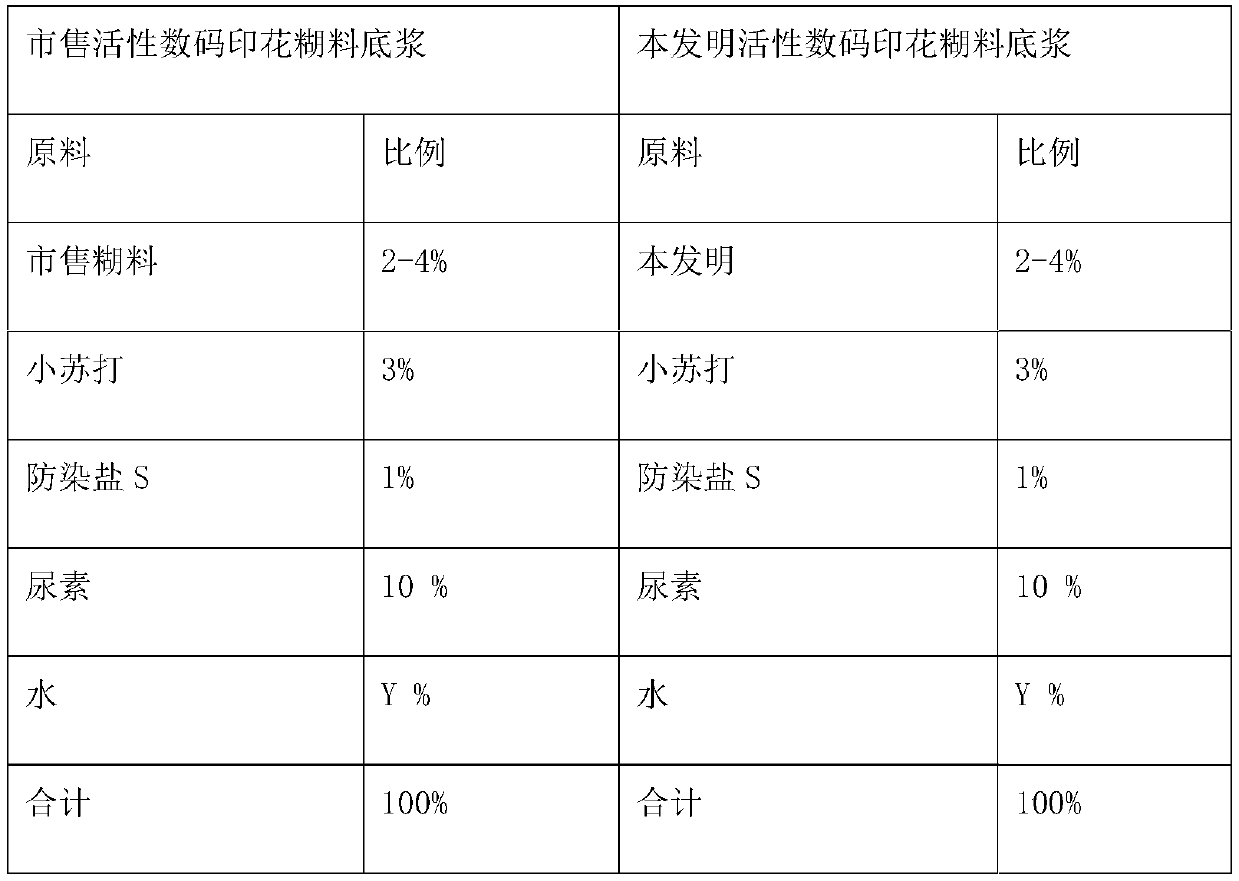

[0050]The formula that present embodiment adopts comprises following raw material:

[0051]

[0052] At about 25°C, mix 6 parts by weight of guar gum hydroxypropyltrimethylammonium chloride and 10 parts by weight of hydroxypropyl guar gum, add 5 parts by weight of hydroxyethyl cellulose and 10 parts by weight of hydroxypropyl Methyl cellulose, then add 2 parts by weight of monoglyceride succinate, 64.2 parts by weight of anhydrous sodium sulfate and 0.8 parts by weight of potassium carbonate, and finally add 2 parts by weight of cocoyl propyl betaine, stir evenly to obtain final product.

Embodiment 2

[0054] The formula that present embodiment adopts comprises following raw material:

[0055]

[0056] At about 25°C, mix 10 parts by weight of guar gum hydroxypropyltrimethylammonium chloride and 15 parts by weight of hydroxypropyl guar gum, add 8 parts by weight of hydroxyethyl cellulose and 16 parts by weight of hydroxypropyl Methyl cellulose, then add 5 parts by weight of monoglyceride succinate, 42 parts by weight of anhydrous sodium sulfate and 1 part by weight of sodium carbonate, and finally add 3 parts by weight of cocamide sulfobetaine, stir evenly to obtain final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com