Rotating printing unit for a machine of the tobacco processing industry

A technology for processing industry and tobacco, which is applied in the field of rotary printing devices for tobacco processing machines, can solve the problems of cigarette rod manufacturing limitations, reduced quality of printed words, unacceptable and other problems, and achieves compact structure, space saving, and uniform printing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

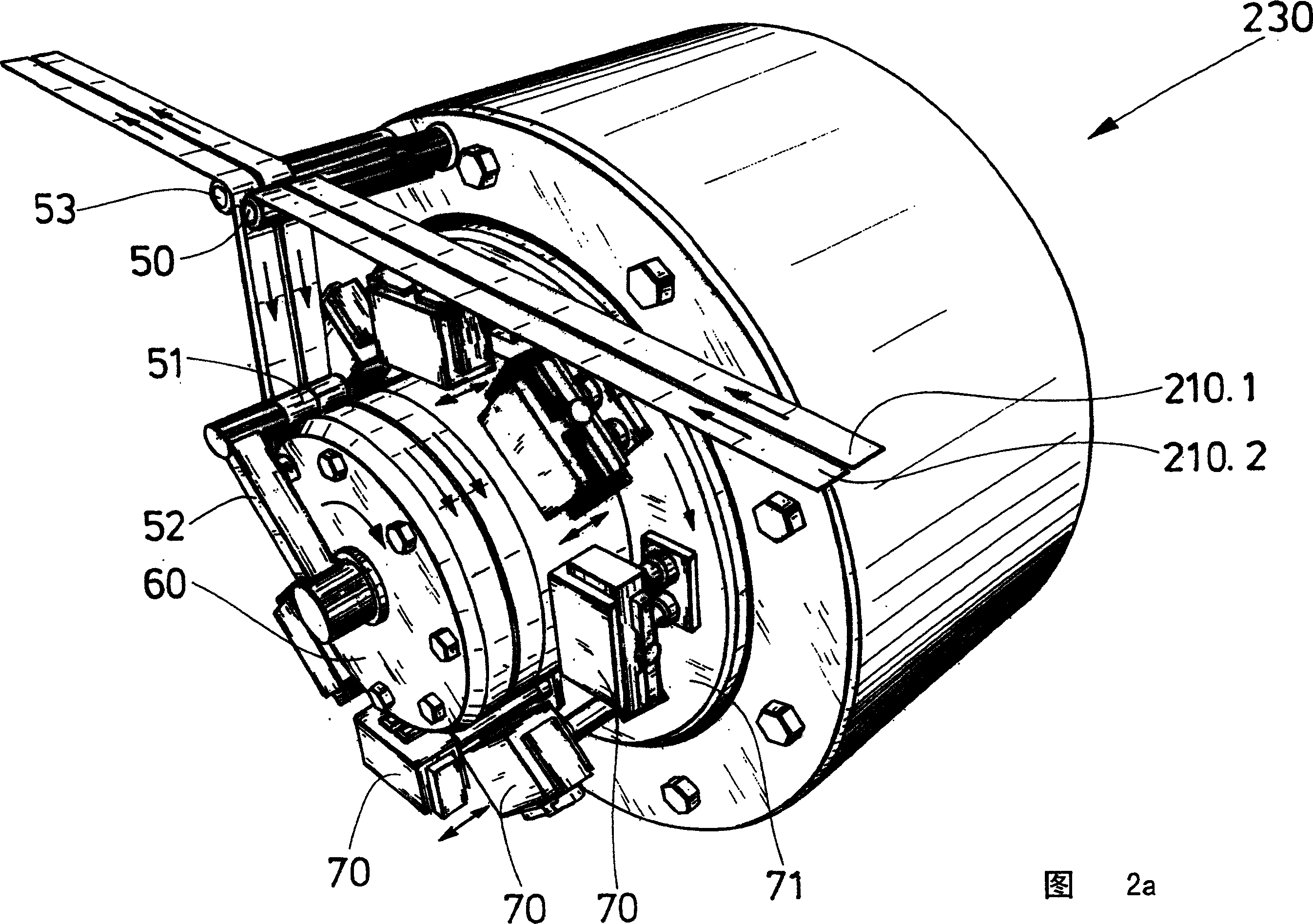

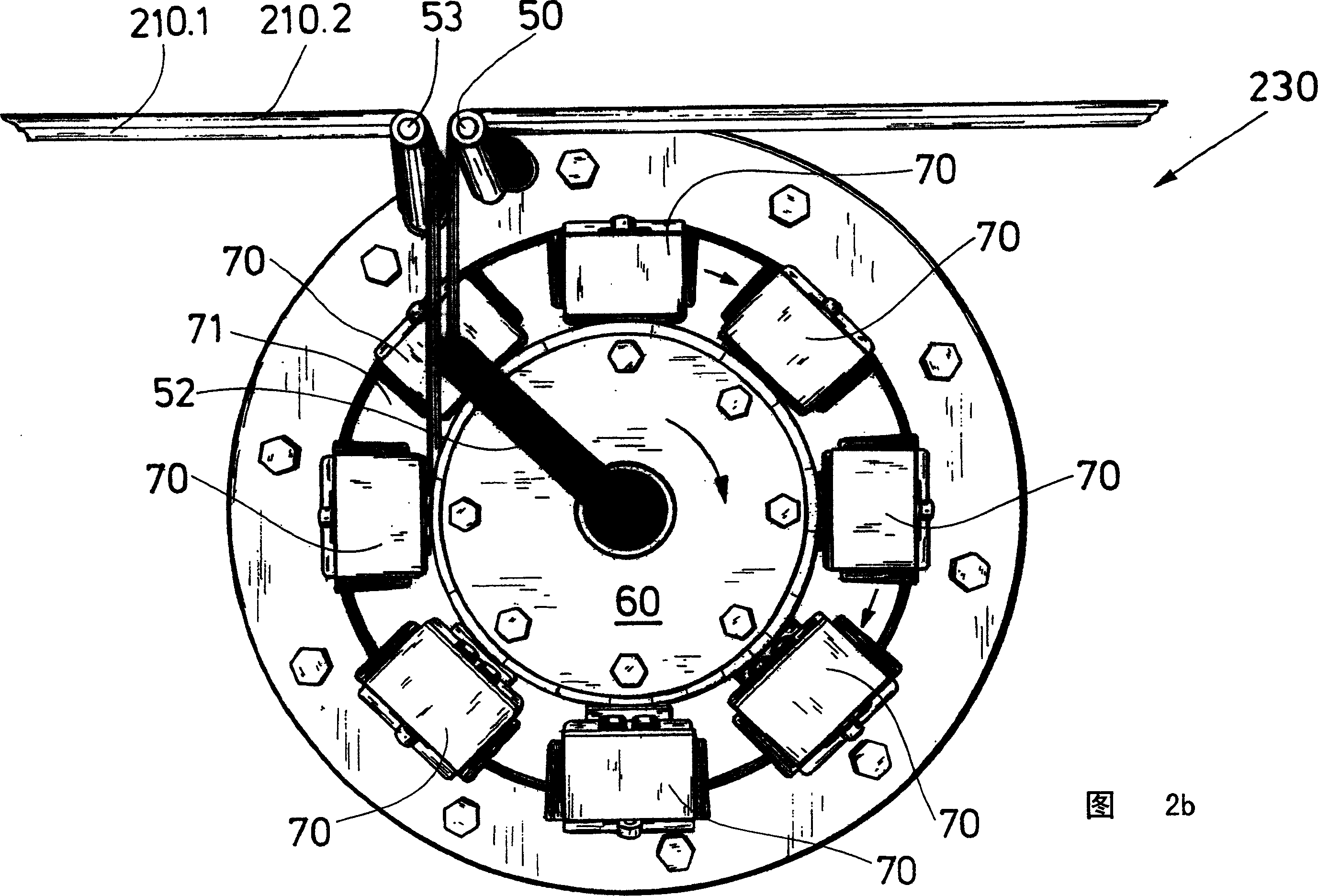

[0037] In the drawings, the same or similar components and corresponding parts use the same reference signs, so the corresponding repeated description will not be made, and only the parts of the embodiment shown in the drawings that are different from the first embodiment will be described.

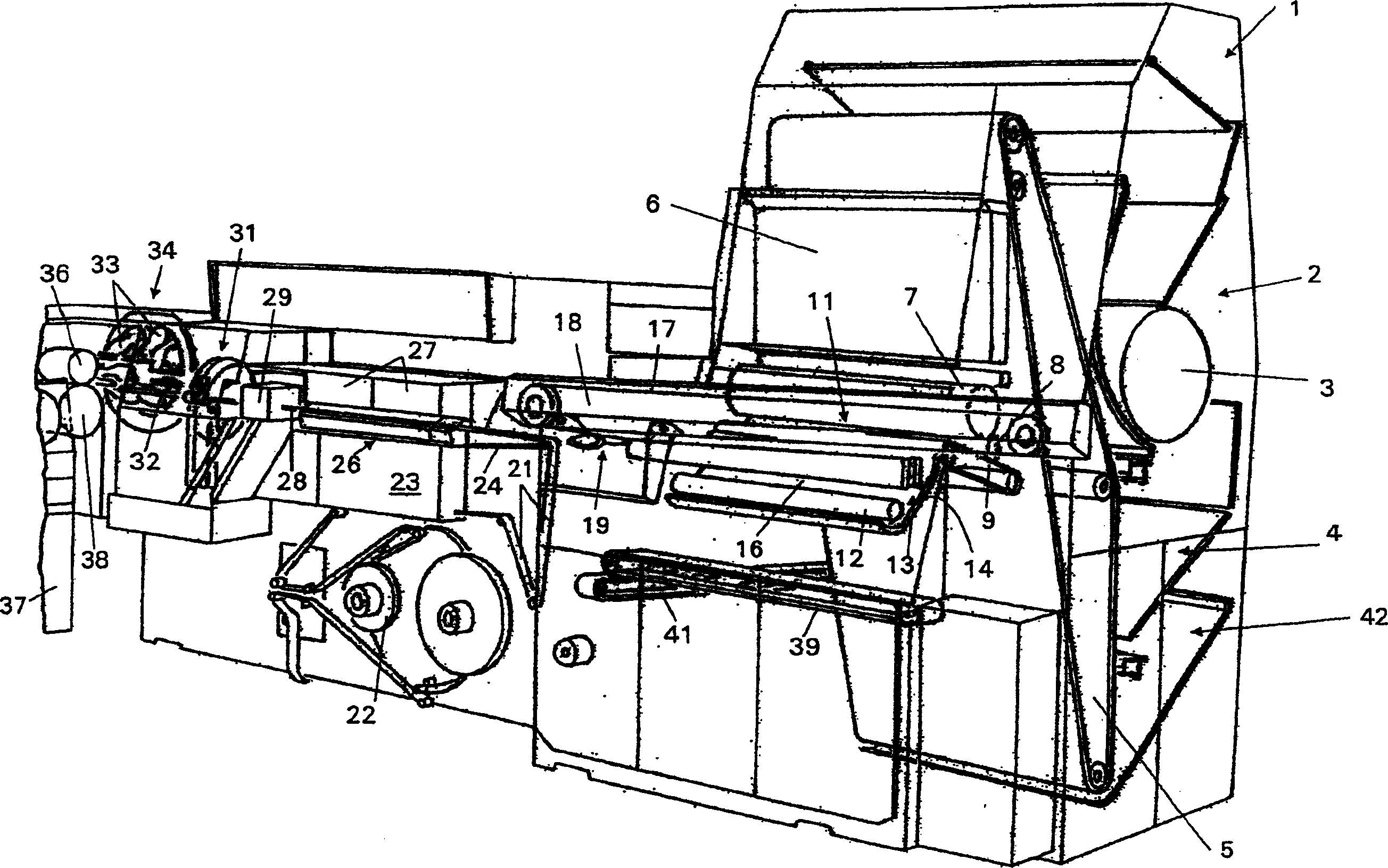

[0038] exist figure 1 In the shown cigarette rod making machine, the gate 1 supplies the predistributor 2 with tobacco portion by portion. The pick-up roller 3 of the pre-distributor 2 is controlled to fill the material preparation container 4 with tobacco, and the high-inclination conveyor 5 takes out the tobacco from the material preparation container 4 and supplies the tobacco to the accumulation well 6 in a controllable manner.

[0039] A pin roll 7 draws a uniformly shaped stream of tobacco from the accumulation well 6, which is driven out of the pins of the pin roll 7 by a beating roll 8 and thrown onto a spreading cloth 9 rotating at a constant speed. The tobacco web formed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com