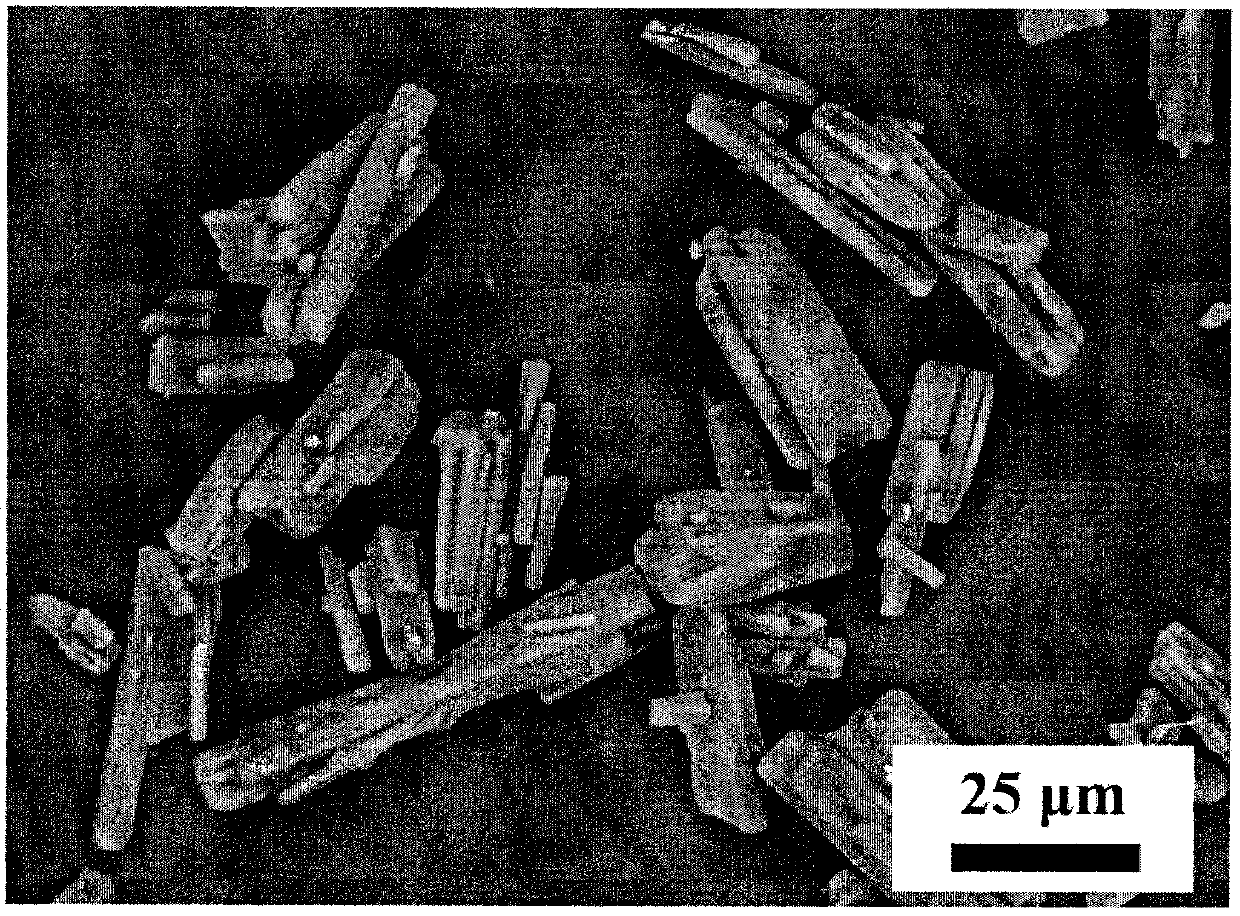

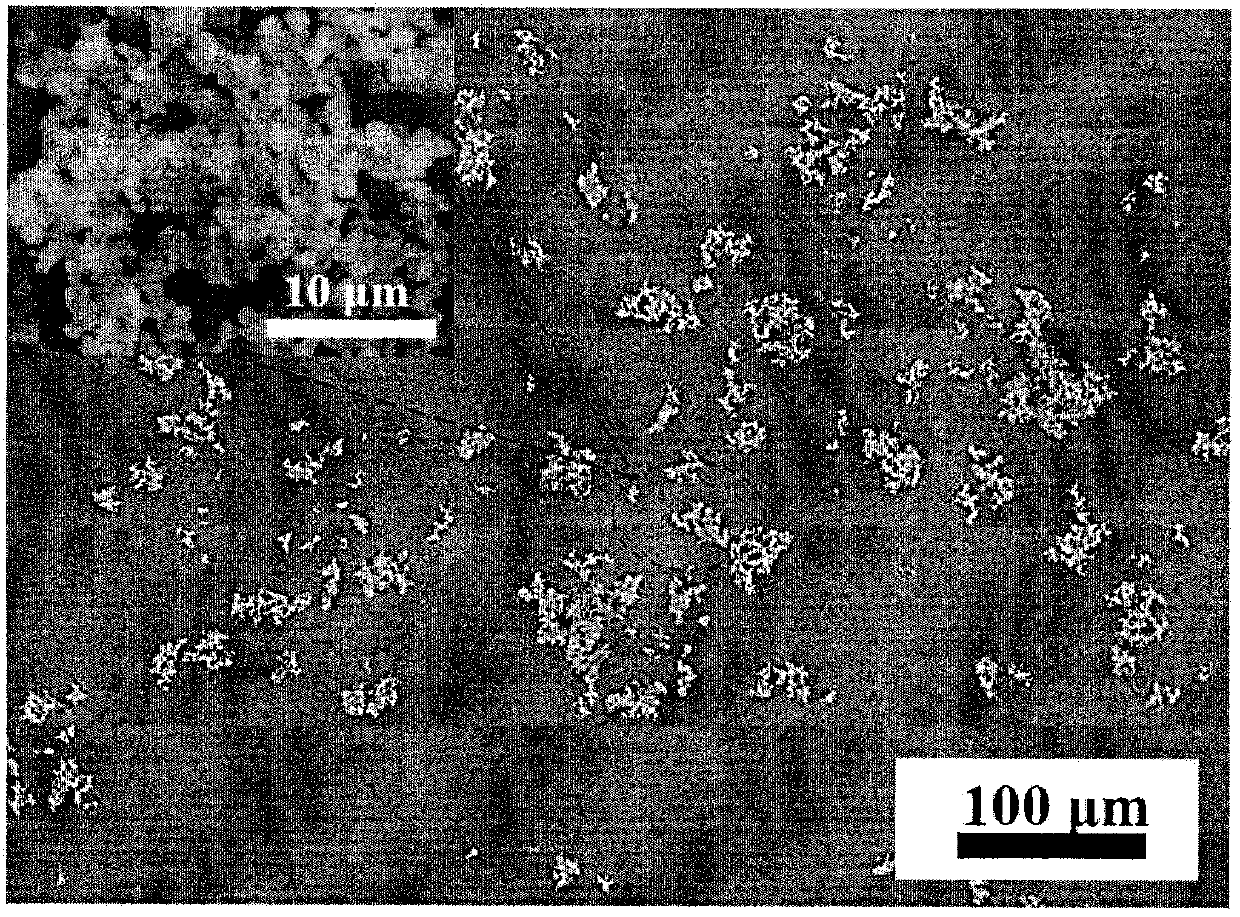

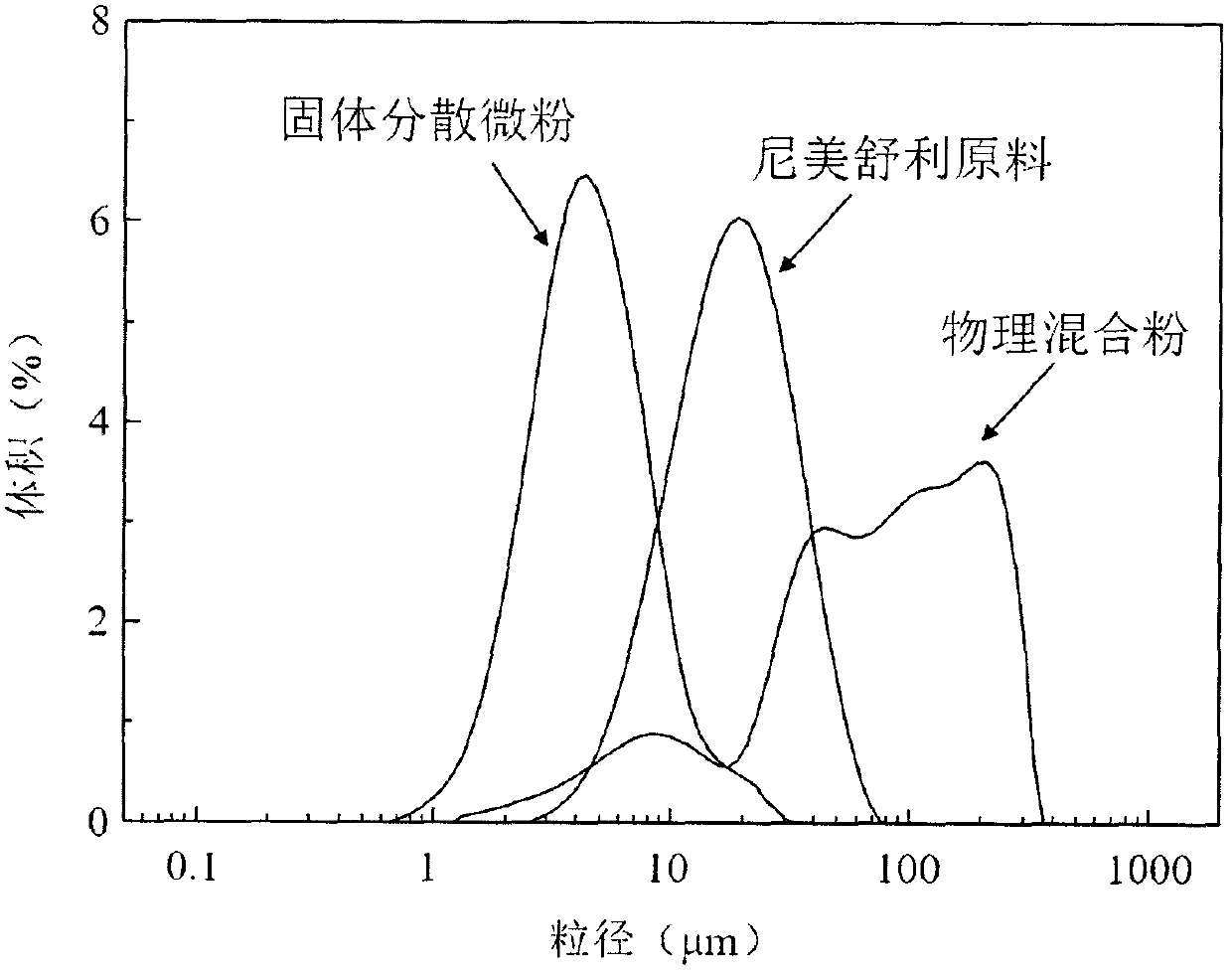

Nimesulide solid dispersion micro-powder and preparation method thereof

A technology of solid dispersion and micropowder, which is applied in the field of solid dispersion micropowder of nimesulide and its preparation, which can solve the problems of low bioavailability, poor solubility of active ingredients, slow dissolution rate, etc., and achieve good dispersion and good stability , the effect of mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] prescription:

[0029] Material composition Prescription ratio (%) Nimesulide 20 PVPK30 40 HPMC 40

[0030] Preparation:

[0031] 1) Preparation of mixed solution: Accurately weigh the mixture of 2.0g nimesulide, 4.0g PVPK30 and 4.0g HPMC and place it in a 500mL conical flask, add 200mL of dichloromethane and methanol mixed solvent (volume ratio 3:1, Containing 0.1% analytically pure hydrochloric acid by volume) to dissolve completely;

[0032] 2) CO 2 Feed: as figure 1 shown, open the CO 2 Cylinder valve, liquefied CO 2 The high-pressure pump is continuously introduced into the high-pressure crystallization kettle of the supercritical fluid crystallization equipment system through the two symmetrical channels of the kettle head (at 60° to the intermediate solution channel), and the flow rate is controlled at 100mL / min, and the inside of the kettle is regulated by the heating device and the pressure regulating valve. The temperatu...

Embodiment 2

[0036] prescription:

[0037] Material composition Prescription ratio (%) Nimesulide 20 PVPK30 30 HPMC 50

[0038] Preparation:

[0039] 1) Preparation of mixed solution: Accurately weigh the mixture of 2.0g nimesulide, 3.0g PVPK30 and 5.0g HPMC and place it in a 500mL conical flask, add 200mL of dichloromethane and methanol mixed solvent (volume ratio 1:1, Containing 0.1% analytically pure hydrochloric acid by volume) to dissolve completely;

[0040] 2) CO 2 Feed: as figure 1 shown, open the CO 2 Cylinder valve, liquefied CO 2 The high-pressure pump is continuously introduced into the high-pressure crystallization kettle of the supercritical fluid crystallization equipment system through the two symmetrical channels of the kettle head (at 60° to the intermediate solution channel), and the flow rate is controlled at 100mL / min, and the inside of the kettle is regulated by the heating device and the pressure regulating valve. The temperatu...

Embodiment 3

[0044] prescription:

[0045] Material composition Prescription ratio (%) Nimesulide 20 PVPK30 20 HPMC 60

[0046] Preparation:

[0047] 1) Preparation of mixed solution: Accurately weigh the mixture of 2.0g nimesulide, 2.0g PVPK30 and 6.0g HPMC and place it in a 500mL conical flask, add 200mL of dichloromethane and methanol mixed solvent (volume ratio 1:1, Containing 0.1% analytically pure hydrochloric acid by volume) to dissolve completely;

[0048] 2) CO 2 Feed: as figure 1 shown, open the CO 2 Cylinder valve, liquefied CO 2 The high-pressure pump is continuously introduced into the high-pressure crystallization kettle of the supercritical fluid crystallization equipment system through the two symmetrical channels of the kettle head (at 60° to the intermediate solution channel), and the flow rate is controlled at 100mL / min, and the inside of the kettle is regulated by the heating device and the pressure regulating valve. The temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com