Boron-nitrogen co-doped carbon nanotube film and preparation method and application thereof

A technology of carbon nanotube film and carbon nanotube, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of inability to achieve large-scale, complex and cumbersome synthesis process, etc., and achieve the goal of improving electrical Chemical properties and structural stability, simple process, good self-supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

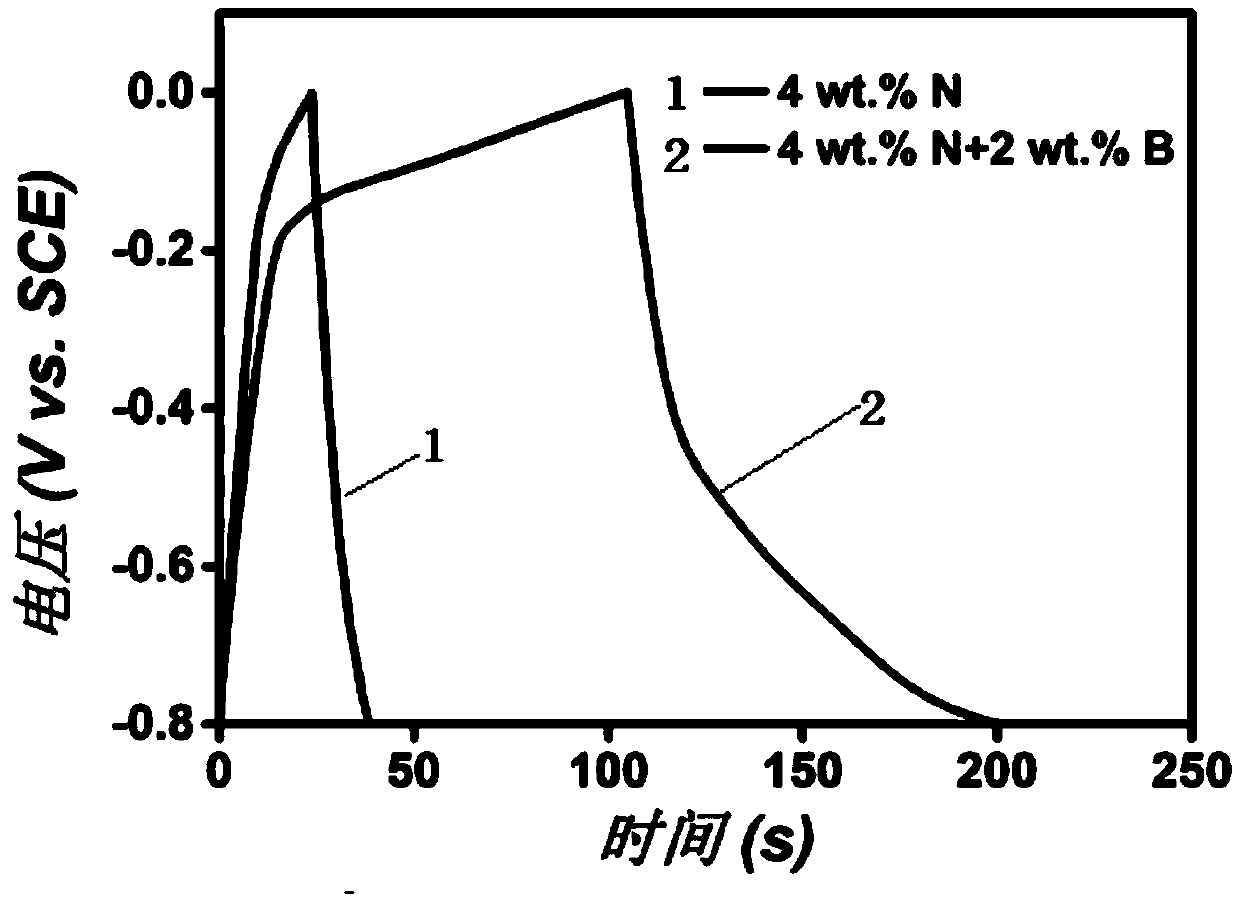

Embodiment 1

[0033] (1) Completely seal the vertical CVD furnace, continuously feed 100 sccm of Ar to remove the air in the furnace, then raise the temperature of the vertical CVD furnace to 1150°C through the temperature controller, and keep it warm for 3 hours to prepare the subsequent carbon nanotube film The growth provides a constant temperature environment;

[0034] (2) Weigh ethanol, ferrocene, thiophene according to the mass ratio of 95:1.5:1, be mixed into solution, wherein ethanol is as carbon source, ferrocene is as catalyst, and thiophene is as promotor; Then on the basis of above-mentioned mixed solution Add 4wt.% pyridine as the nitrogen source for the reaction, and disperse the above solution by ultrasonic for 30 minutes at a temperature of 50°C to obtain a uniform dispersion and transfer it to a syringe as a precursor solution;

[0035] (3) After steps (1) and (2) are completed, turn off the inert gas and continuously feed 800 sccm of H 2 As a reagent gas up to H 2 Fill t...

Embodiment 2

[0038] (1) Completely seal the vertical CVD furnace, continuously feed 100 sccm of Ar to remove the air in the furnace, then raise the temperature of the vertical CVD furnace to 1150°C through the temperature controller, and keep it warm for 3 hours to prepare the subsequent carbon nanotube film The growth provides a constant temperature environment;

[0039] (2) Weigh ethanol, ferrocene, thiophene according to the mass ratio of 95:1.5:1, be mixed into solution, wherein ethanol is as carbon source, ferrocene is as catalyst, and thiophene is as promotor; Then on the basis of above-mentioned mixed solution Add 4wt.% of pyridine and 2wt.% of boric acid as the nitrogen source and boron source of the reaction respectively, and disperse the above solution by ultrasonic for 30min at a temperature of 50°C to obtain a uniform dispersion and transfer it to a syringe as a pre- body solution;

[0040] (3) After steps (1) and (2) are completed, turn off the inert gas and continuously feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com