Preparation method of NiMnGaCoCu memory alloy thin strip

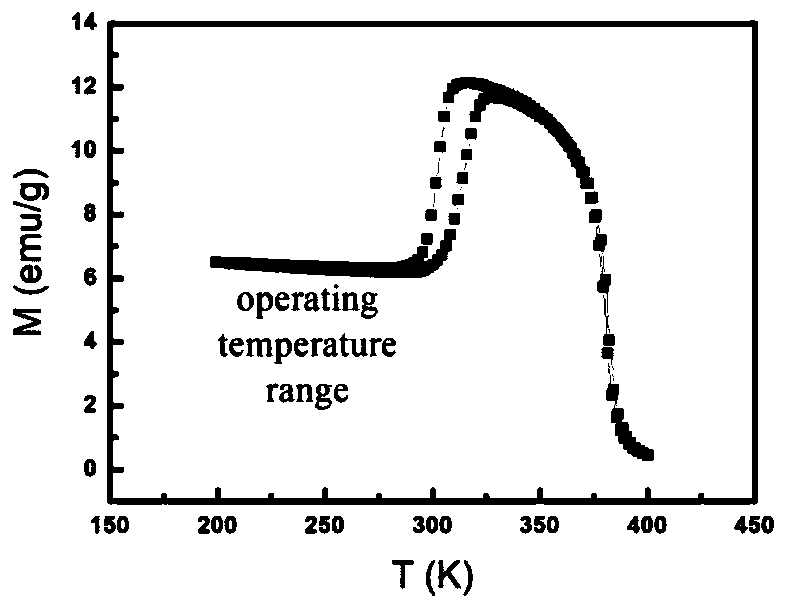

A memory alloy and strip technology, which is applied in the field of preparation of NiMnGaCoCu memory alloy thin strips, can solve problems such as volatility and material composition changes, and achieve adjustable lattice distortion, wide temperature control range, and magnetically controlled shape memory good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of Ni 45 mn 24 Ga 23 co 4 Cu 4 A method for preparing memory alloy thin strips, comprising the steps of:

[0035] 1) Melting: Select pure Ni, Mn, Ga, Co, Cu metal raw materials and place them in a vacuum melting furnace, fill in an inert gas after vacuuming, turn over and melt 3 times under the protection of an inert gas, and the uniform alloy solution after stirring is cooled in water Obtain NiMnGaCoCu alloy ingot after fully cooling in the copper mold;

[0036] 2) The first heat treatment;

[0037] 3) Rapid quenching: the heat-treated NiMnGaCoCu alloy ingot is melted and rapidly quenched in a smelting and spinning furnace with a rotation speed of 20m / s to make alloy thin strips;

[0038] 4) second heat treatment to obtain NiMnGaCoCu memory alloy thin strips;

[0039] Further, the first heat treatment in step 2) is to raise the temperature of the NiMnGaCoCu alloy ingot obtained in step 1) to 900°C at a rate of 5°C / min, heat preservation treatment for 24h,...

Embodiment 2

[0054] A kind of Ni 45 mn 24 Ga 23 co 4 Cu 4 A method for preparing memory alloy thin strips, comprising the steps of:

[0055] 1) Melting: Select pure Ni, Mn, Ga, Co, Cu metal raw materials and place them in a vacuum melting furnace, fill in an inert gas after vacuuming, turn over and melt 3 times under the protection of an inert gas, and the uniform alloy solution after stirring is cooled in water Obtain NiMnGaCoCu alloy ingot after fully cooling in the copper mold;

[0056] 2) The first heat treatment;

[0057] 3) Rapid quenching: the heat-treated NiMnGaCoCu alloy ingot is melted and rapidly quenched in a smelting and spinning furnace with a rotation speed of 20m / s to make alloy thin strips;

[0058] 4) second heat treatment to obtain NiMnGaCoCu memory alloy thin strips;

[0059] Further, the first heat treatment in step 2) is to raise the temperature of the NiMnGaCoCu alloy ingot obtained in step 1) to 900°C at a rate of 5°C / min, heat it for 24 hours, and then cool ...

Embodiment 3

[0065] A kind of Ni 46 mn 27 Ga 22 co 4 Cu 3.4 A method for preparing memory alloy thin strips, comprising the steps of:

[0066] 1) Melting: Select pure Ni, Mn, Ga, Co, Cu metal raw materials and place them in a vacuum melting furnace, fill in an inert gas after vacuuming, turn over and melt 4 times under the protection of an inert gas, and stir the uniform alloy solution in water cooling Obtain NiMnGaCoCu alloy ingot after fully cooling in the copper mold;

[0067] 2) The first heat treatment;

[0068] 3) Rapid quenching: the heat-treated NiMnGaCoCu alloy ingot is melted and rapidly quenched in a smelting and spinning furnace with a rotation speed of 20m / s to make alloy thin strips;

[0069] 4) second heat treatment to obtain NiMnGaCoCu memory alloy thin strips;

[0070] Further, the first heat treatment in step 2) is to raise the temperature of the NiMnGaCoCu alloy ingot obtained in step 1) to 900°C at a rate of 5°C / min, heat preservation treatment for 24h, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com