Fluorinated polyurethane coating and preparation method of super-hydrophobic coating

A technology of fluorinated polyurethane and superhydrophobic coatings, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of unsatisfactory adhesion strength between coatings and substrates, limited mobility of low surface energy segments, and difficulty in blending and dispersing To achieve efficient preparation and other issues, to achieve the effects of good self-cleaning performance, excellent self-healing performance, and high surface migration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

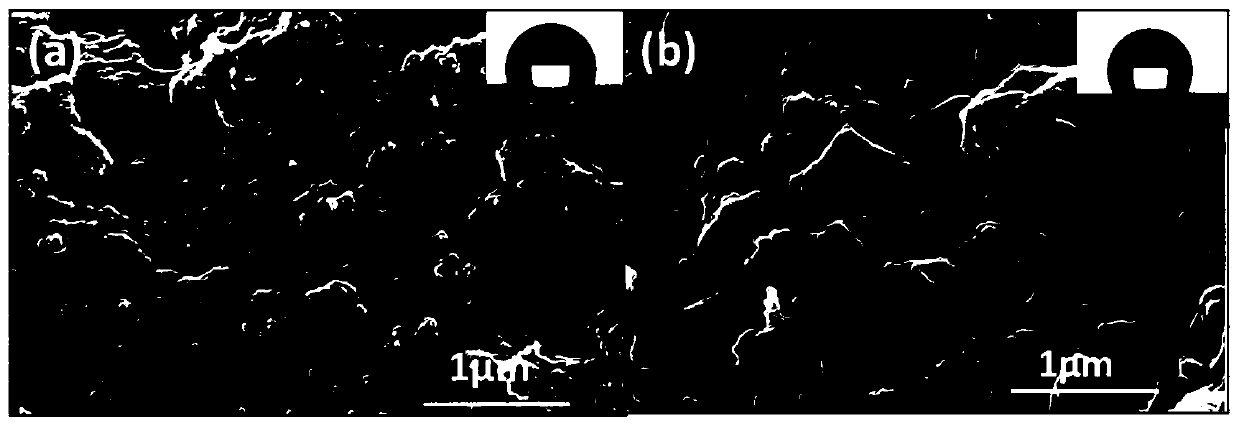

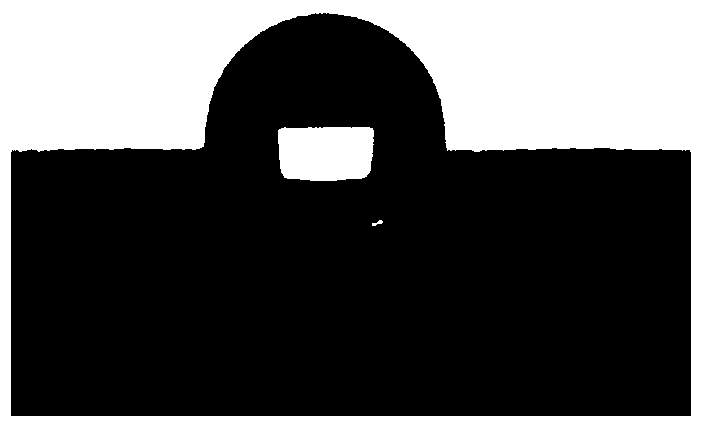

[0039] Example 1: Superhydrophobic coating coated glass surface

[0040](1) Glass surface pretreatment: soak the glass plate in 2.5M NaOH solution for 24 hours, take it out and sonicate it in distilled water for 10 minutes. Then the glass plate was soaked in 0.1M HCl solution for 15 minutes, and after taking it out, it was ultrasonicated in distilled water and methanol for 10 minutes respectively. Finally, it was washed several times with distilled water and dried in an oven for later use.

[0041] (2) Preparation of fluorinated mercaptan prepolymer: Add 4.89 g of pentaerythritol tetramercapto propionate, 10.56 g of 2-(perfluorooctyl) ethyl methacrylate, and 0.1 g of 184 initiator in the reactor , Acetone 15g. React for 40 minutes under ultraviolet light and normal temperature conditions. The free radical addition thiol click reaction initiated by the photoinitiator has the characteristics of high-efficiency reaction. The infrared test shows that the infrared peaks of the e...

Embodiment 2

[0046] Embodiment 2: superhydrophobic coating coats PET fiber cloth

[0047] (1) Preparation of fluorinated mercaptan prepolymer: 3.98 g of trimethylolpropane trimercaptopropyl ester, 5.18 g of 2-(perfluorooctyl) ethyl methacrylate, and 184 Agent 0.08g, acetone 7.33g. React for 40 minutes under ultraviolet light and normal temperature conditions.

[0048] (2) Preparation of fluorinated polyurethane coating: Add 0.28 g of 4,4'-dicyclohexylmethane diisocyanate successively in a new reactor, dehydrated polytetrahydrofuran diol (M n =1000) 0.5g, dehydrated acetone 0.39g, 1 drop of dibutyltin dilaurate. The reaction was carried out at 60°C for 2 hours. Then, 0.195 g of the fluorinated thiol prepolymer prepared in (1) was added to the reactor, and acetone was added until a well-dispersed suspension was obtained, and the reaction was continued at 60° C. for 2 h. Finally, 0.037 g of chain extender neopentyl glycol was added, and the reaction was continued for 2 hours.

[0049] (3...

Embodiment 3

[0052] Embodiment 3: superhydrophobic coating coats PC surface (without chain extender)

[0053] (1) Preparation of fluorinated mercaptan prepolymer: add hexa(3-mercaptopropionic acid) dipentaerythritol ester 7.83g, 2-(perfluorooctyl) ethyl methacrylate 20.72g successively in the reactor, 0.157g of 184 initiator, 57.1g of acetone. React for 40 minutes under ultraviolet light and normal temperature conditions.

[0054] (2) Preparation of fluorinated polyurethane coating: add isophorone diisocyanate 0.22g successively in new reactor, dehydrated polyoxypropylene glycol (M n =1000) 0.75g, dehydrated acetone 0.97g, 1 drop of triethylamine. The reaction was carried out at 80°C for 2 hours. Then, 0.97 g of the fluorinated mercaptan prepolymer prepared in (1) was added to the reactor, and acetone was added until a well-dispersed suspension was obtained, and the reaction was continued at 80° C. for 2 h.

[0055] (3) Preparation of super-hydrophobic coating: Add 0.394 g of hydrophil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com