Fast-curing radar wave absorbing putty, preparation method and applications thereof

A wave-absorbing putty and rapid curing technology, which is applied in chemical instruments and methods, other chemical processes, filling slurries, etc., can solve problems such as hardening and brittleness, changing electromagnetic properties, and materials becoming soft and sticky. The effects of microwave absorption and mechanical properties, fast curing speed and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

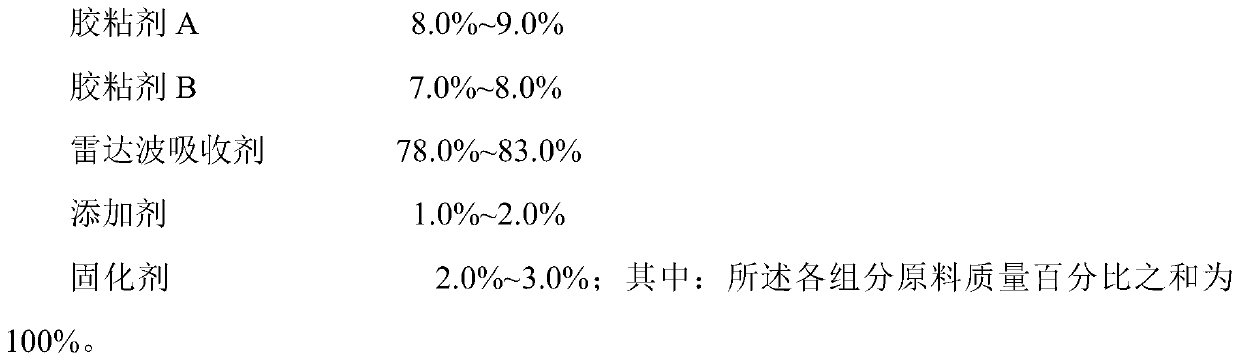

[0036] A kind of fast-curing radar wave-absorbing putty of the present embodiment, described fast-curing radar wave-absorbing putty, is made of 23g epoxy resin, 21g polyurethane modified epoxy resin, 3.5g anti-sag additive, 197g radar wave absorber and 8g curing agent composition;

[0037] Wherein: the anti-sag additive contains polyamide wax; the radar wave absorber contains carbonyl iron, ferrosilicate, and ferrosilicon chromium powder; the curing agent contains 3,5-dimethylthiotoluenediamine.

[0038] The above-mentioned fast-curing radar absorbing putty is prepared by the following method, and the steps are as follows:

[0039] (1) Add 23g of epoxy resin, 21g of polyurethane modified epoxy resin, and 3.5g of anti-sag additive into the beaker, and stir it with a high-speed mixer, and set the stirring speed at 800-1000rpm;

[0040] (2) After stirring for 60 minutes, set the speed to 500-600rpm, slowly add 197g of radar wave absorber and 8g of curing agent, after adding the ...

Embodiment 2

[0043] A kind of fast-curing radar wave-absorbing putty of the present embodiment, described fast-curing radar wave-absorbing putty, is made of 47g epoxy resin, 42g polyurethane modified epoxy resin, 7g anti-sag additive, 395g radar wave absorber and 16g Curing agent composition;

[0044] Among them: the anti-sag additive contains BYK-410 thixotropic anti-settling agent, the radar wave absorber contains carbonyl iron, iron silicon chromium powder; the curing agent contains 3,5-dimethylthiotoluenediamine and 3,5-Diethyltoluenediamine.

[0045] The above-mentioned fast-curing radar absorbing putty is prepared by the following method, and the steps are as follows:

[0046] (1) Add 47g of epoxy resin, 42g of polyurethane modified epoxy resin, and 7g of anti-sag additive into the beaker, and stir it with a high-speed mixer, and set the stirring speed at 800-1000rpm;

[0047] (2) After stirring for 60 minutes, set the speed to 500-600rpm, slowly add 395g of radar wave absorber and...

Embodiment 3

[0051] A kind of fast-curing radar wave-absorbing putty of the present embodiment, described fast-curing radar wave-absorbing putty, is made of 72g epoxy resin, 64g polyurethane modified epoxy resin, 14g anti-sag additive, 840g radar wave absorber and 24g Curing agent composition;

[0052] Wherein: the anti-sag additive contains polyamide wax; the radar wave absorber contains carbonyl iron and iron silicon chromium powder; the curing agent contains 3,5-diethyltoluene diamine.

[0053] The above-mentioned fast-curing radar absorbing putty is prepared by the following method, and the steps are as follows:

[0054] (1) Add 72g of epoxy resin, 64g of polyurethane modified epoxy resin, and 14g of anti-sag additive into the beaker, and stir it with a high-speed mixer, and set the stirring speed at 800-1000rpm;

[0055] (2) After stirring for 60 minutes, set the speed to 500-600rpm, slowly add 840g of radar wave absorber and 24g of curing agent, after adding the radar wave absorber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com