A kind of fir bark wood-based panel adhesive

A technology for adhesives and wood-based panels, which is applied in the direction of adhesives, adhesive types, and wooden veneer joints, etc., and can solve the problem of affecting the mechanical properties of the adhesive layer, large molecular weight, insufficient crosslinking of aldehydes or crosslinking agents, etc. problem, to achieve the effect of low cost, good bonding performance, and high moisture content of the veneer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

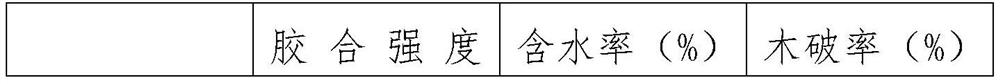

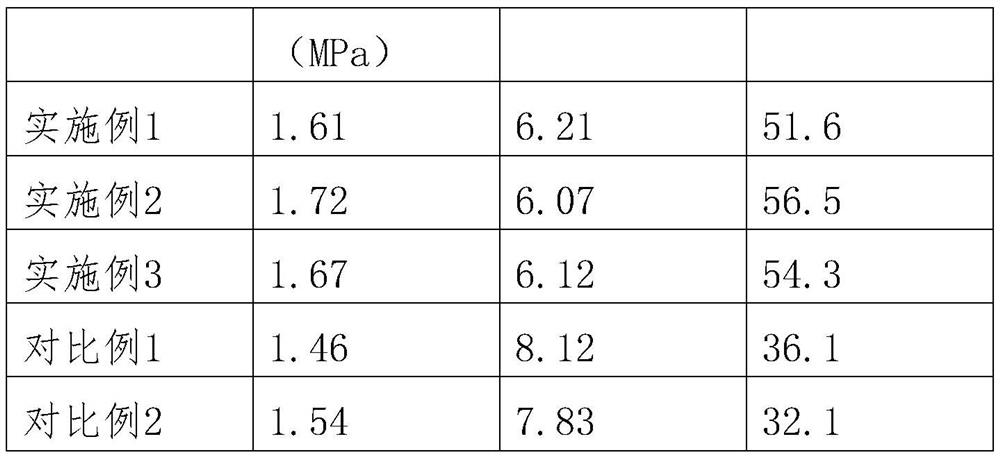

Examples

Embodiment 1

[0020] Components: 80g fir bark powder, 40g urea-formaldehyde resin, 80g phenol, 3g urea, 1g mica powder, 1g gypsum powder, 0.5g nano silicon oxide, 0.1g polymethylhydrogen siloxane.

[0021] The particle size of the Chinese fir bark powder is 60 mesh, and the particle size of gypsum powder and mica powder is 150 mesh.

[0022] The preparation method of Chinese fir bark wood-based panel adhesive comprises the following processes:

[0023] (1) After mixing the Chinese fir bark powder and 6% sodium hydroxide solution at a mass ratio of 1:5, stir and heat to 80°C, and keep warm for 1.5h;

[0024] (2) After the material in step (1) is cooled to 60°C, add phenol and keep it warm for 25 minutes; then continue cooling to 50°C, add urea, and keep it warm for 6 minutes, then add mica powder, gypsum powder, nano silicon oxide, and oxane Surfactants were mixed and stirred for 3 minutes to obtain bark glue;

[0025] (3) Mix the bark glue with the urea-formaldehyde resin at room temperat...

Embodiment 2

[0029] Components: 85g fir bark powder, 50g urea-formaldehyde resin, 82g phenol, 4g urea, 1.2g mica powder, 1.8g gypsum powder, 0.55g nano silicon oxide, 0.15g polymethylhydrogen siloxane.

[0030] The particle size of the Chinese fir bark powder is 70 mesh, and the particle size of gypsum powder and mica powder is 150 mesh.

[0031] The preparation method of Chinese fir bark wood-based panel adhesive comprises the following processes:

[0032] (1) After mixing Chinese fir bark powder and 6% sodium hydroxide solution at a mass ratio of 1:6, stir and heat to 95°C, and keep warm for 1.2h;

[0033] (2) After the material in step (1) is cooled to 65°C, add phenol, and keep it warm for 22 minutes; then continue to cool to 45°C, add urea, and keep it warm for 8 minutes, then add mica powder, gypsum powder, nano silicon oxide, oxane Surfactants were mixed and stirred for 4 minutes to obtain bark glue;

[0034] (3) Mix the bark glue with the urea-formaldehyde resin at room temperatu...

Embodiment 3

[0038] Components: 100g fir bark powder, 60g urea-formaldehyde resin, 85g phenol, 5g urea, 2g mica powder, 2g gypsum powder, 0.6g nano silicon oxide, 0.2g polymethylhydrogen siloxane.

[0039] The particle size of the Chinese fir bark powder is 70 mesh, and the particle size of gypsum powder and mica powder is 160 mesh.

[0040] The preparation method of Chinese fir bark wood-based panel adhesive comprises the following processes:

[0041] (1) After mixing the Chinese fir bark powder and 8% sodium hydroxide solution in a mass ratio of 1:6, stir and heat to 100° C., and keep warm for 1 hour;

[0042] (2) After the material in step (1) is cooled to 70°C, add phenol, and keep it warm for 20 minutes; then continue to cool to 40°C, add urea, and keep it warm for 10 minutes, then add mica powder, gypsum powder, nano silicon oxide, oxane Surfactants were mixed and stirred for 5 minutes to obtain bark glue;

[0043] (3) Mix bark glue with urea-formaldehyde resin and stir evenly at r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com