Lithium ion battery electrolytic solution treatment method

A lithium-ion battery and treatment method technology, which is applied in the field of lithium-ion battery electrolyte cleaning treatment, can solve the problems of reducing fluorine content and high fluorine content, and achieve the effects of reducing fluorine content, increasing hydrolysis efficiency, and improving hydrolysis completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

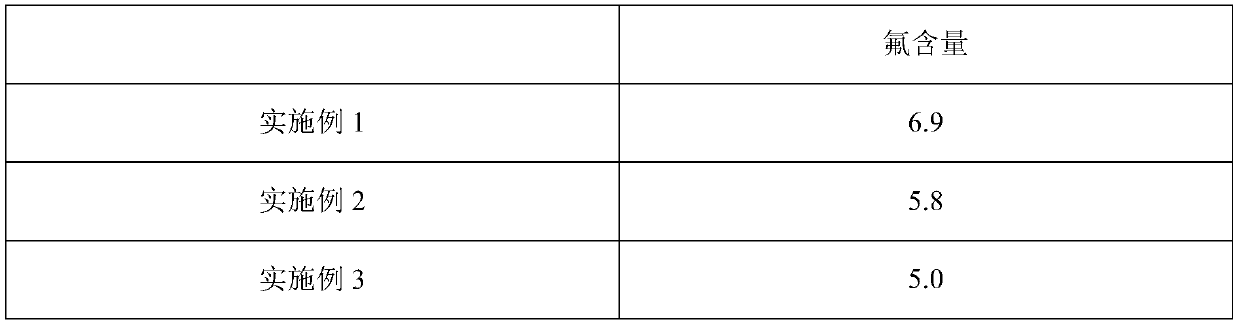

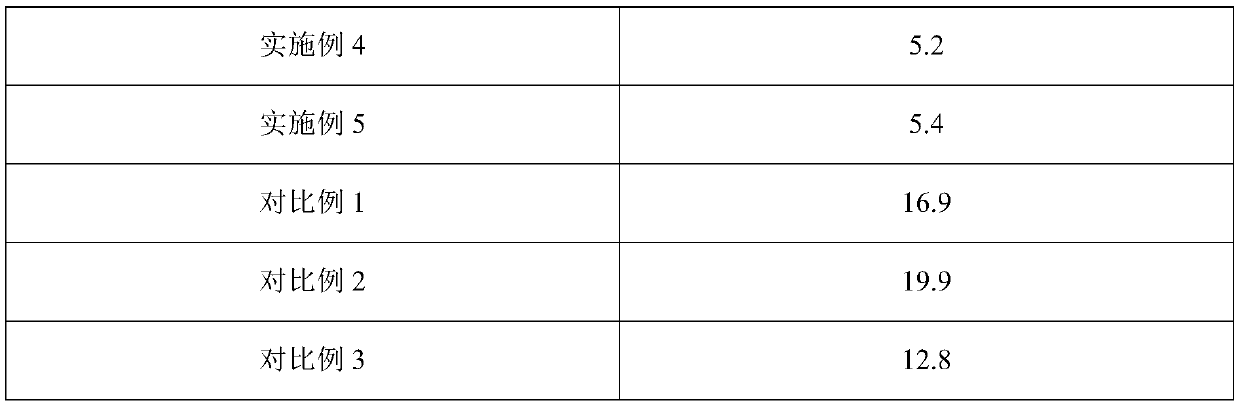

Examples

Embodiment 1

[0029] A lithium-ion battery electrolyte treatment method, comprising the steps of:

[0030] (1) prepare calcium hydroxide solution;

[0031] (2) adding the acid solution to the lithium-ion battery electrolyte for hydrolysis treatment to obtain a hydrolyzate;

[0032] (3) adding calcium hydroxide solution dropwise to the hydrolyzate and stirring to generate waste gas and solid-liquid mixture;

[0033] (4) Absorb and separate the waste gas, and flocculate and separate the solid-liquid mixture.

Embodiment 2

[0035] A lithium-ion battery electrolyte treatment method, comprising the steps of:

[0036] (1) prepare calcium hydroxide solution, wherein, by mass, calcium hydroxide: water=1:10;

[0037] (2) Add 1mol / L hydrochloric acid to lithium ion battery electrolyte and carry out hydrolysis treatment to obtain hydrolyzate, wherein, hydrochloric acid: lithium ion battery electrolyte=0.05:1;

[0038] (3) At 25°C, add calcium hydroxide solution dropwise to the hydrolyzed solution and stir to generate waste gas and solid-liquid mixture, wherein, lithium hexafluorophosphate: calcium hydroxide = 1:1.5;

[0039] (4) Carry out absorption treatment, sedimentation treatment and separation treatment on exhaust gas, carry out flocculation precipitation treatment and separation treatment on solid-liquid mixture, choose calcium hydroxide solution for absorption treatment, water in calcium hydroxide solution: calcium hydroxide=10:1 , Alum is selected as the flocculant.

Embodiment 3

[0041] A lithium-ion battery electrolyte treatment method, comprising the steps of:

[0042] (1) prepare calcium hydroxide solution, wherein, by mass, calcium hydroxide: water=1:20;

[0043] (2) Add 1mol / L hydrochloric acid to lithium ion battery electrolyte and carry out hydrolysis treatment to obtain hydrolyzate, wherein, hydrochloric acid: lithium ion battery electrolyte=0.1:1;

[0044] (3) At 30°C, add calcium hydroxide solution dropwise to the hydrolyzed solution and stir to generate waste gas and solid-liquid mixture, wherein, lithium hexafluorophosphate: calcium hydroxide = 1:2;

[0045] (4) Carry out absorption treatment, sedimentation treatment and separation treatment on exhaust gas, carry out flocculation precipitation treatment and separation treatment on solid-liquid mixture, choose calcium hydroxide solution for absorption treatment, water in calcium hydroxide solution: calcium hydroxide=14:1 , The flocculant is ferric chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com