Ink-jet printing method, ink-jet printing device and display device

An inkjet printing device and inkjet printing technology, which are applied in the fields of electrical solid devices, semiconductor devices, semiconductor/solid device manufacturing, etc., can solve the problems of poor film formation, high cost, and inability to produce large-size OLED devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

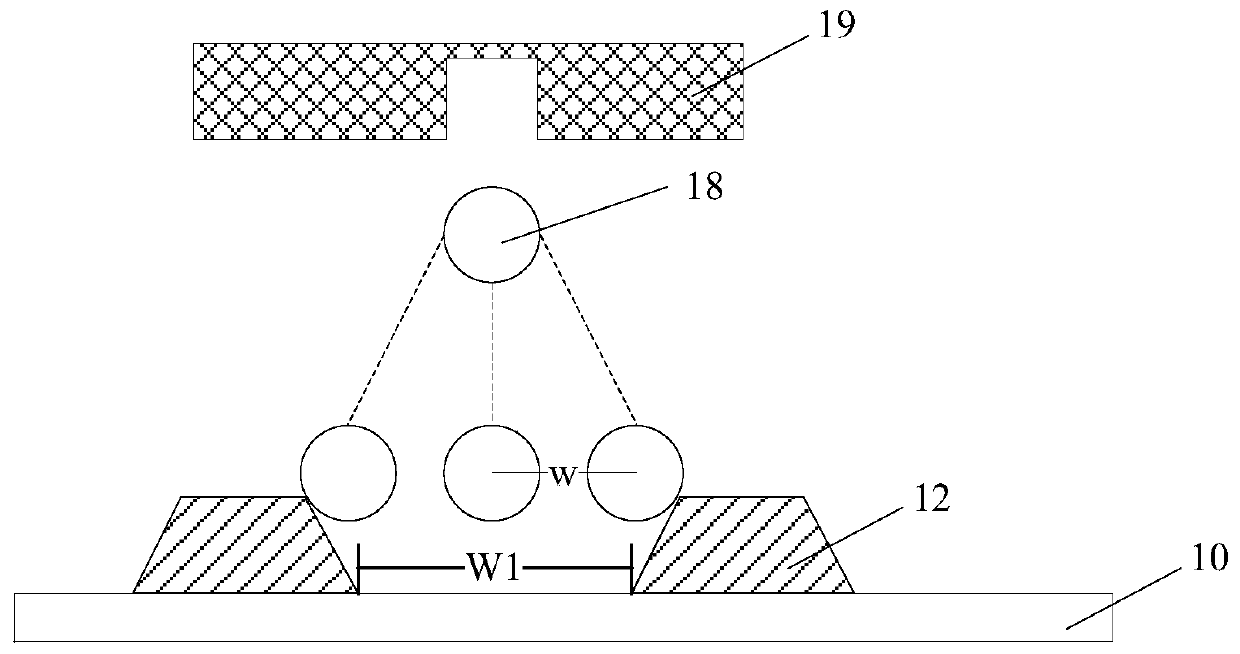

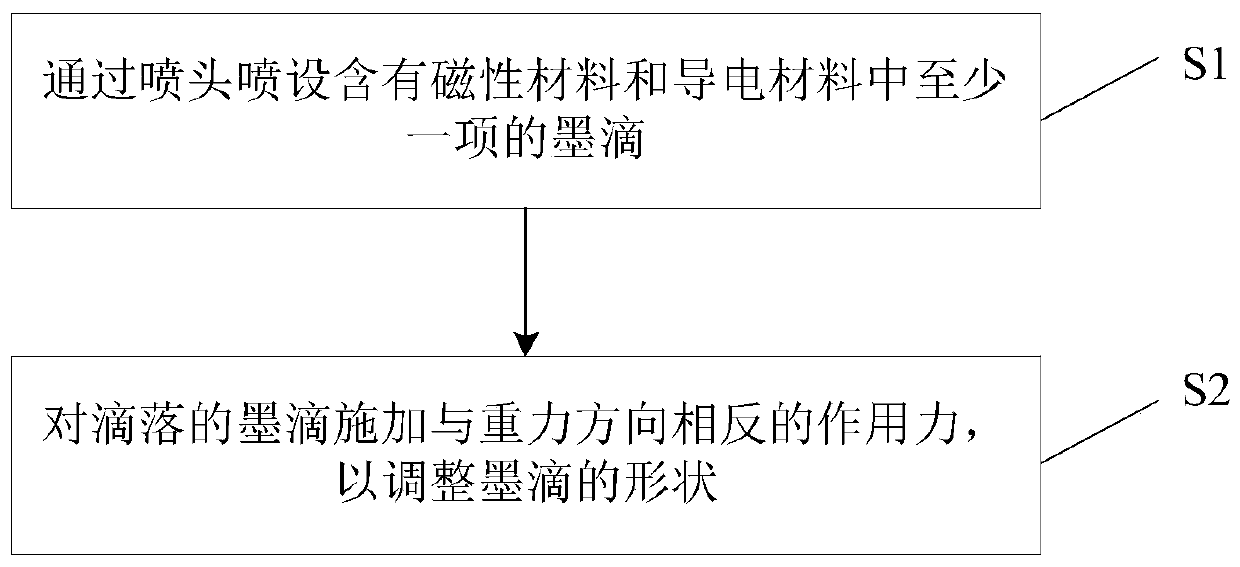

[0035] The inkjet printing method provided in this embodiment includes: spraying ink droplets containing magnetic materials through a nozzle; applying a magnetic force opposite to the direction of gravity to the dropped ink droplets to adjust the shape of the ink droplets.

[0036] In this embodiment, the magnetic material may include at least one of the following: magnetic nanoparticle material, magnetic ionic liquid material. For example, the magnetic material may be a magnetic nanoparticle material, or may be a magnetic ionic liquid material, or may be a combination of a magnetic nanoparticle material and a magnetic ionic liquid material.

[0037] In this embodiment, the particle size of the magnetic nanoparticle material is less than 30 nanometers (nm), and the magnetic nanoparticle material can have superparamagnetic properties, that is, the magnetic hysteresis property disappears, and there is no residual magnetism, so that it will not affect the inkjet printing solution....

no. 2 example

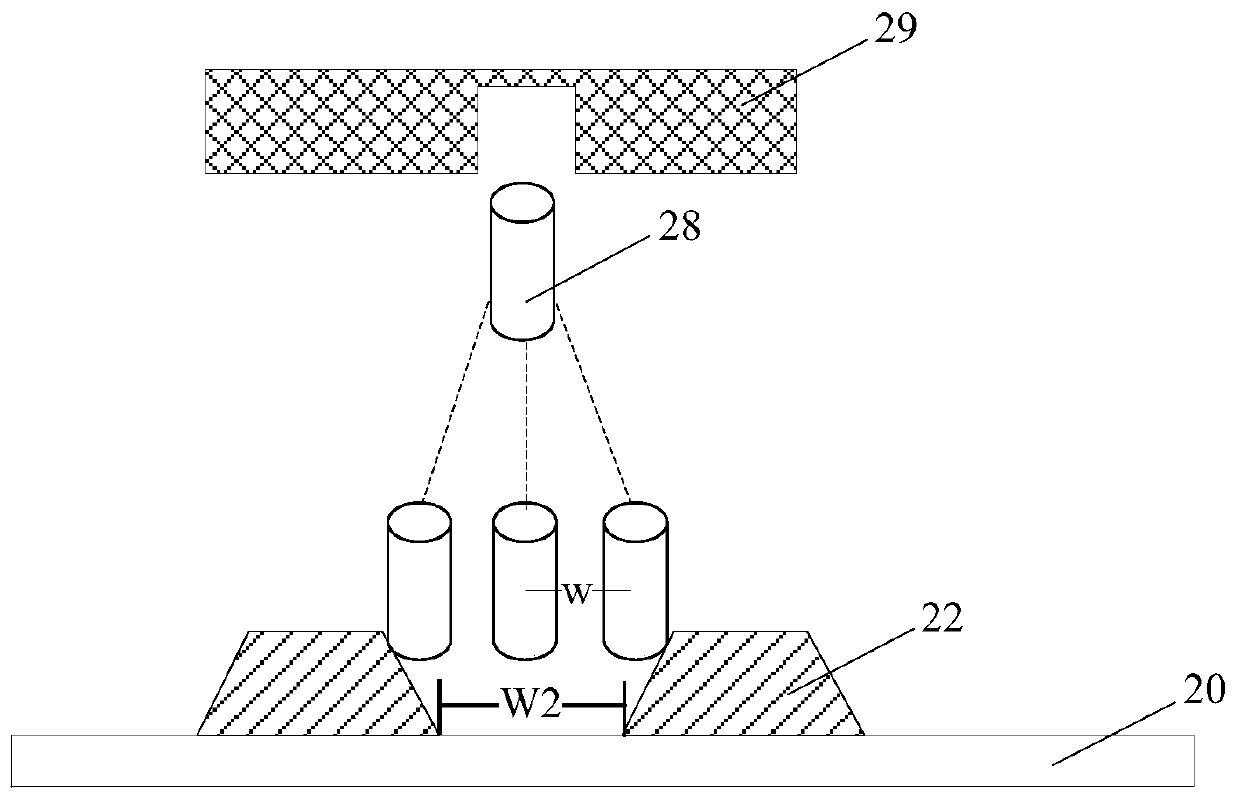

[0044] The inkjet printing method provided in this embodiment includes: spraying ink droplets containing conductive materials through a nozzle; and applying an electric field force opposite to the direction of gravity to the dropped ink droplets to adjust the shape of the ink droplets.

[0045] In an exemplary embodiment, the conductive material may include at least one of the following: colloidal particles adsorbing cations, and colloidal particles adsorbing anions. For example, colloidal particles such as metal hydroxides and metal oxides adsorb cations and are positively charged; colloidal particles such as non-metal oxides and non-metal sulfides adsorb anions and are negatively charged. However, the present application is not limited to this.

[0046] In an exemplary embodiment, the total amount of the conductive material in the ink droplet may be less than 5% of the total amount of the ink droplet, so as to avoid affecting the basic performance of the ink and the prepared...

no. 3 example

[0049] Based on the technical concept of the embodiment of the present application, the embodiment of the present application also provides a display device, including: an anode layer, an organic functional layer and a cathode layer stacked in sequence; wherein, the organic functional layer uses the Prepared by inkjet printing method. Wherein, the organic functional layer may include one or more of the following: a hole injection layer, a hole transport layer, a light emitting layer, an electron transport layer, and an electron injection layer.

[0050] The technical solution of this embodiment will be further described below through the manufacturing process of the display device of this embodiment. Among them, the "patterning process" mentioned in this embodiment includes deposition of film layer, coating of photoresist, mask exposure, development, etching, stripping of photoresist, etc., which is a mature preparation process in related technologies. Deposition can use know...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com