Nitrogen-doped porous carbon-coated hydrogen storage alloy powder and preparation method thereof

A nitrogen-doped porous carbon and hydrogen storage alloy technology, which is applied in the field of hydrogen storage alloys, can solve the problem that dynamic performance and cycle stability cannot be optimized at the same time, and achieve good kinetic performance and good cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16 and comparative example 1~9

[0062] Carry out experimental detection to embodiment 1~16 and comparative example 1~9:

[0063] 1. SEM and XRD detection:

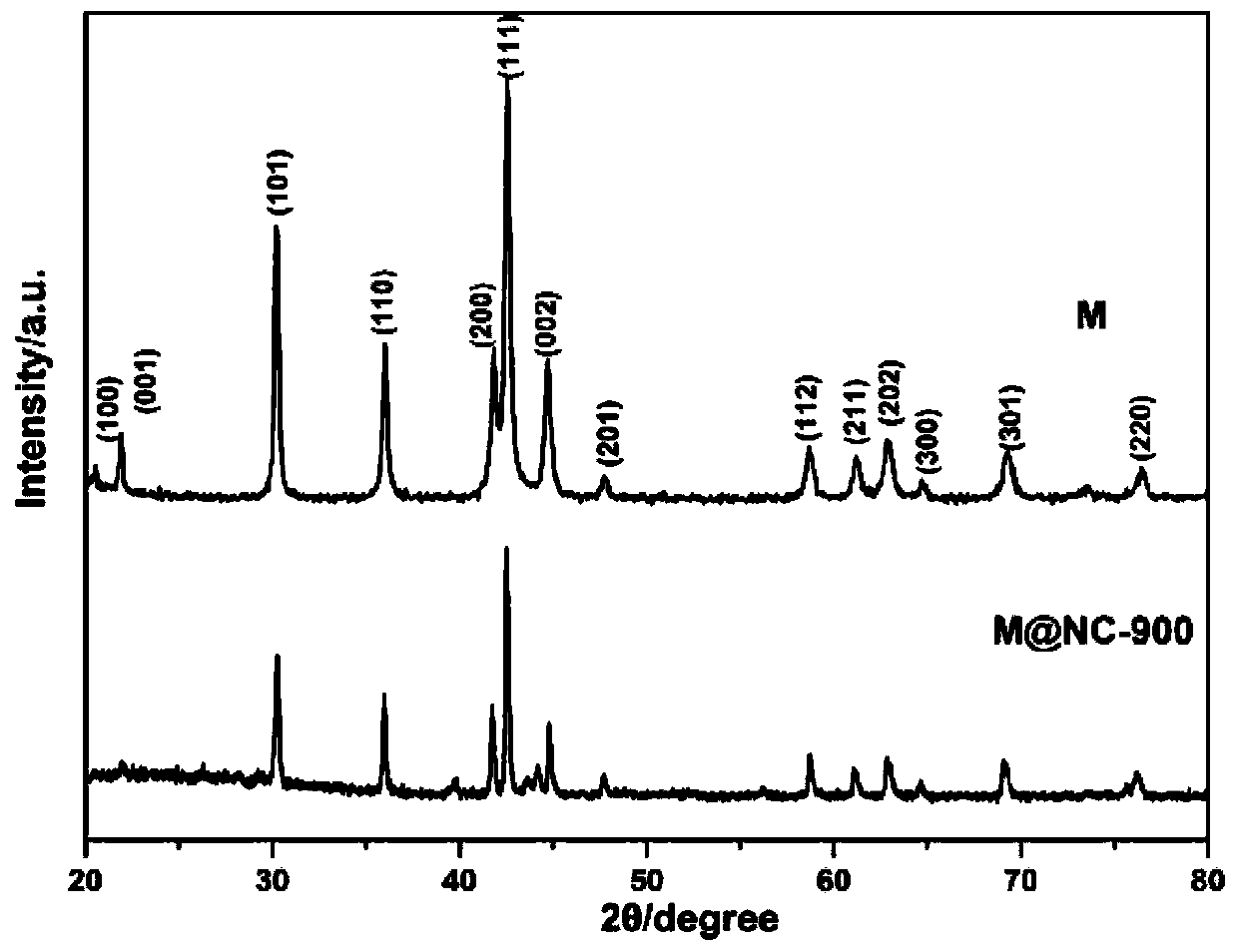

[0064] Adopt scanning electron microscope and X-ray diffractometer to detect embodiment 1~16 and comparative example 1~9, take embodiment 1 and comparative example 1 as example, detection result is as follows Figure 1~4 shown.

[0065] in figure 1 The X-ray diffraction patterns of the second powder (M@NC-900) obtained in Example 1 and Comparative Example 1 (M); from the XRD analysis results, it can be seen that the crystal structure of the hydrogen storage alloy has not changed, and the CaCu 5 crystal structure, and the strongest peak of the hydrogen storage alloy becomes sharper, indicating that the crystallinity becomes better.

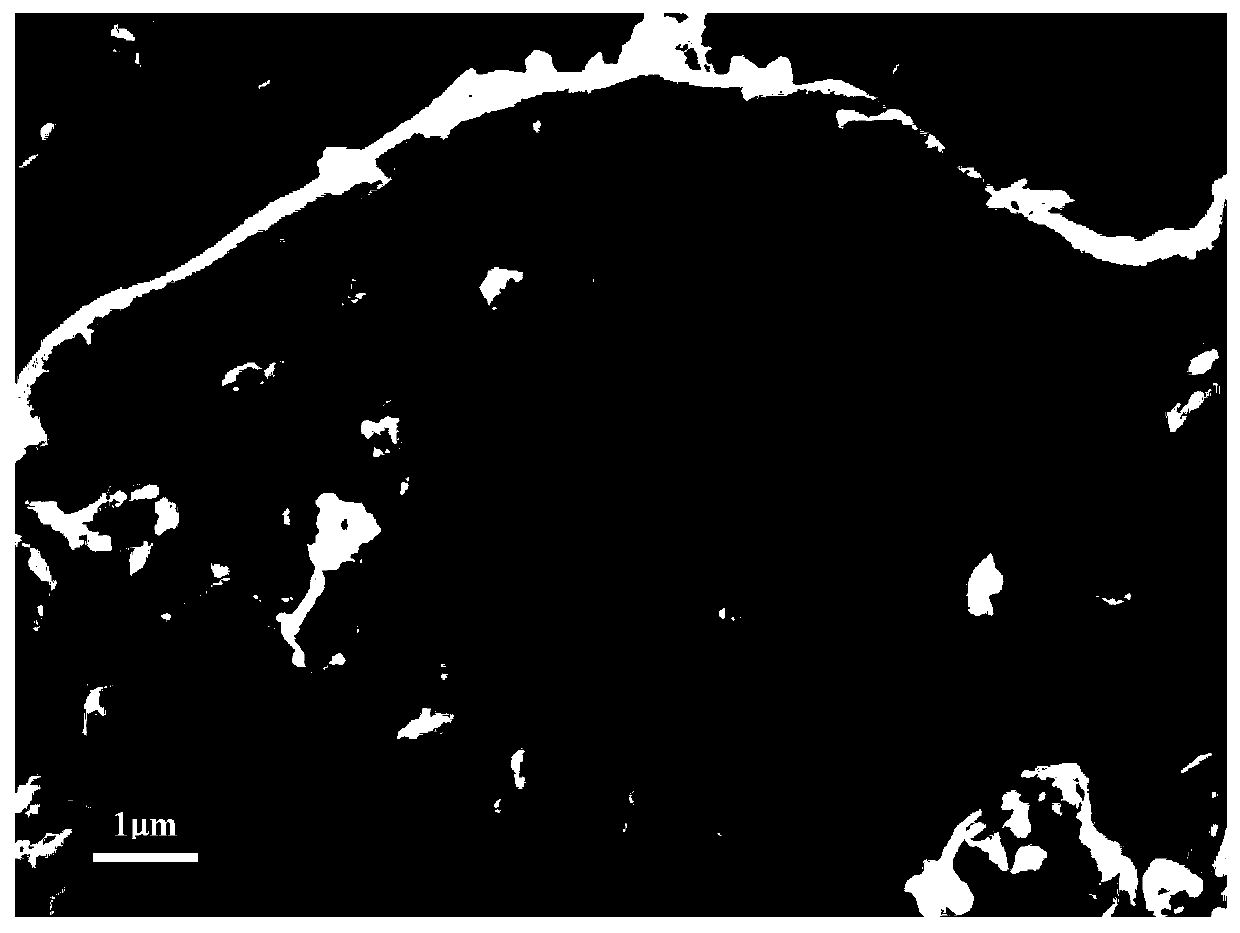

[0066] figure 2 It is the SEM topography figure of comparative example 1 (M), and the magnification is 10000 times, image 3 It is the SEM topography figure of the first powder (M@Zif-8) in Example 1, the magnification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com