Electrostatic dust removal device

An electrostatic precipitator and dust-collecting board technology, which is applied in the field of electrostatic precipitator, can solve the problems of affecting the electrostatic field of the discharge electrode and the dust-collecting board, affecting the adsorption effect of the dust-collecting board, and reducing the dust-removing ability of the electrostatic precipitator equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

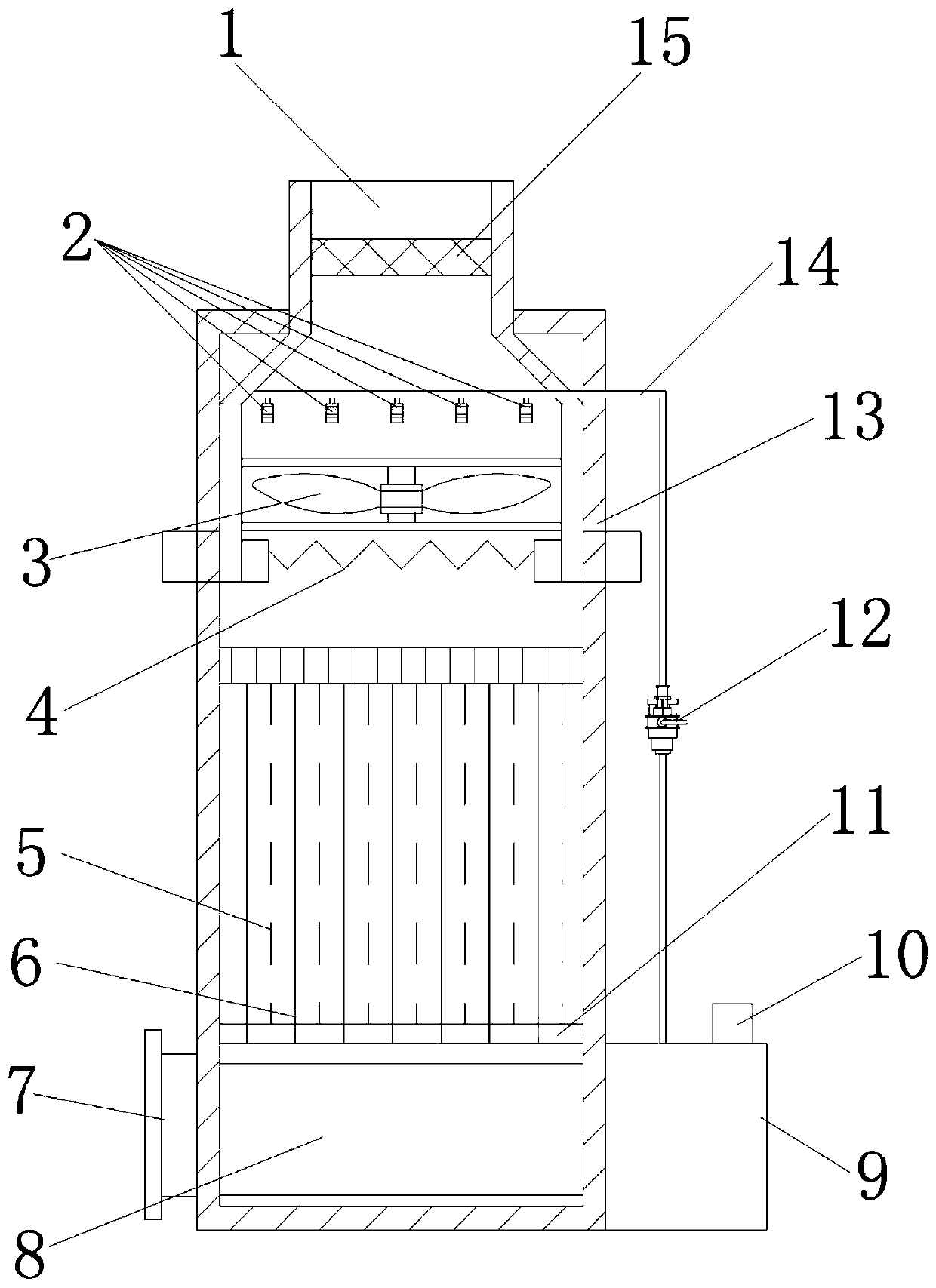

[0028] refer to figure 1 , an electrostatic precipitator provided by the present invention, comprising: an outer box body 13, an air inlet pipe 1 and an air outlet pipe 7, the outer box body 13 is in a barrel-shaped structure, and one end of the air inlet pipe 1 is installed on the top of the outer box body 13 and extends To the inside of the outer box body 13, an activated carbon filter screen 15 is provided in the air intake pipe 1 to initially filter the gas in the air intake pipe 1, and the end of the air intake pipe 1 pierced to the inside of the outer box body 13 is provided with a funnel-shaped mouth. The diameter of the opening is the same as the inner diameter of the outer box 13, so that the filtered gas enters the outer box 13; the upper part of the inner wall of the outer box 13 is provided with a fan 3, and the bottom of the fan 3 is provided with a heating wire 4, and the two ends of the heating wire 4 are connected To the two ends of the output line of the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com