Zero-dimensional black phosphorus quantum dot/one-dimensional tubular carbon nitride composite photocatalyst and preparation method thereof

A zero-dimensional black phosphorus and carbon nitride technology, used in physical/chemical process catalysts, chemical instruments and methods, special compound water treatment, etc., can solve the limitations of wide application of photocatalytic technology, insufficient photocatalytic activity, poor stability, etc. problem, to achieve the effect of strong separation and migration ability of photogenerated carriers, high use value and application prospects, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

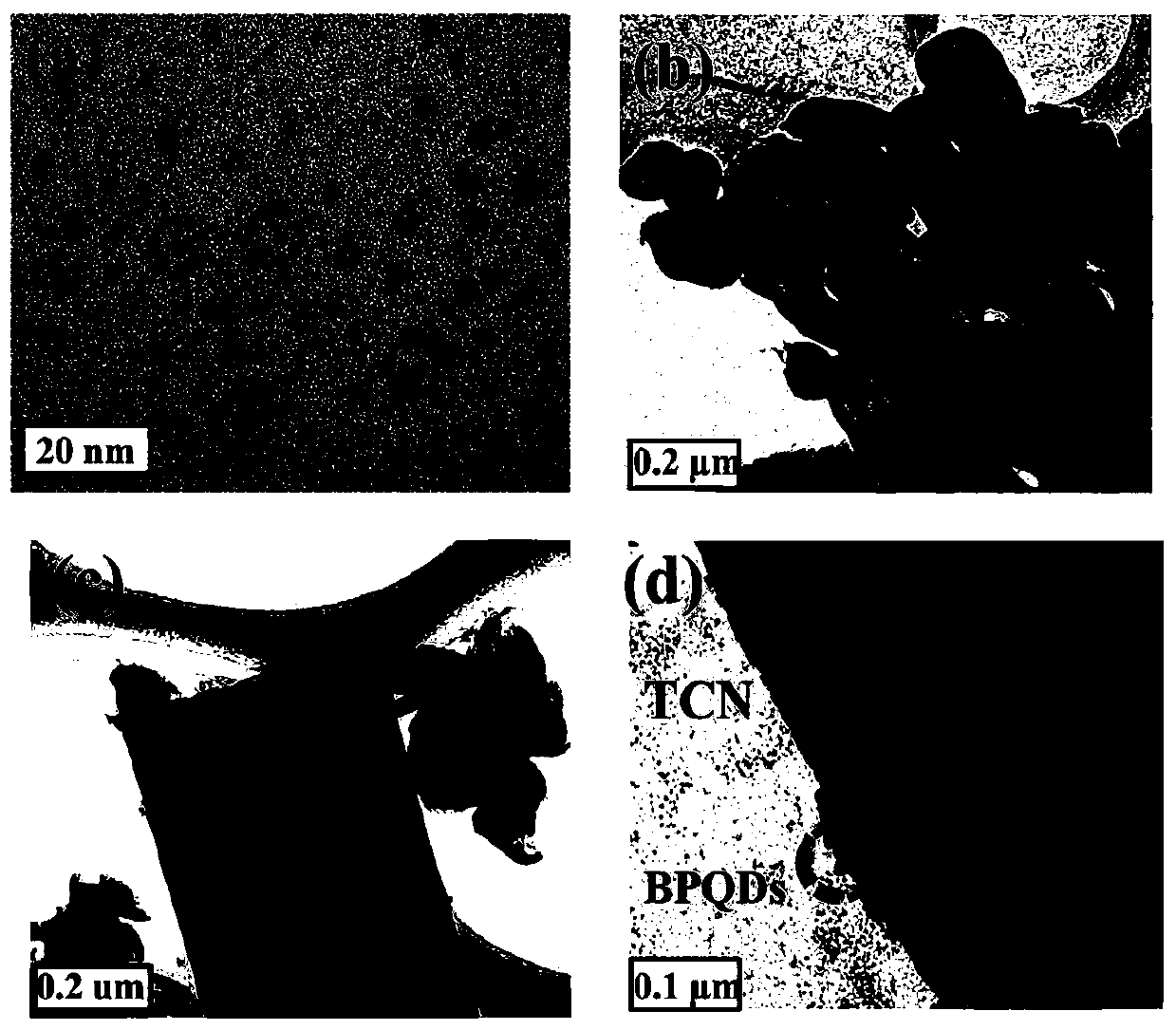

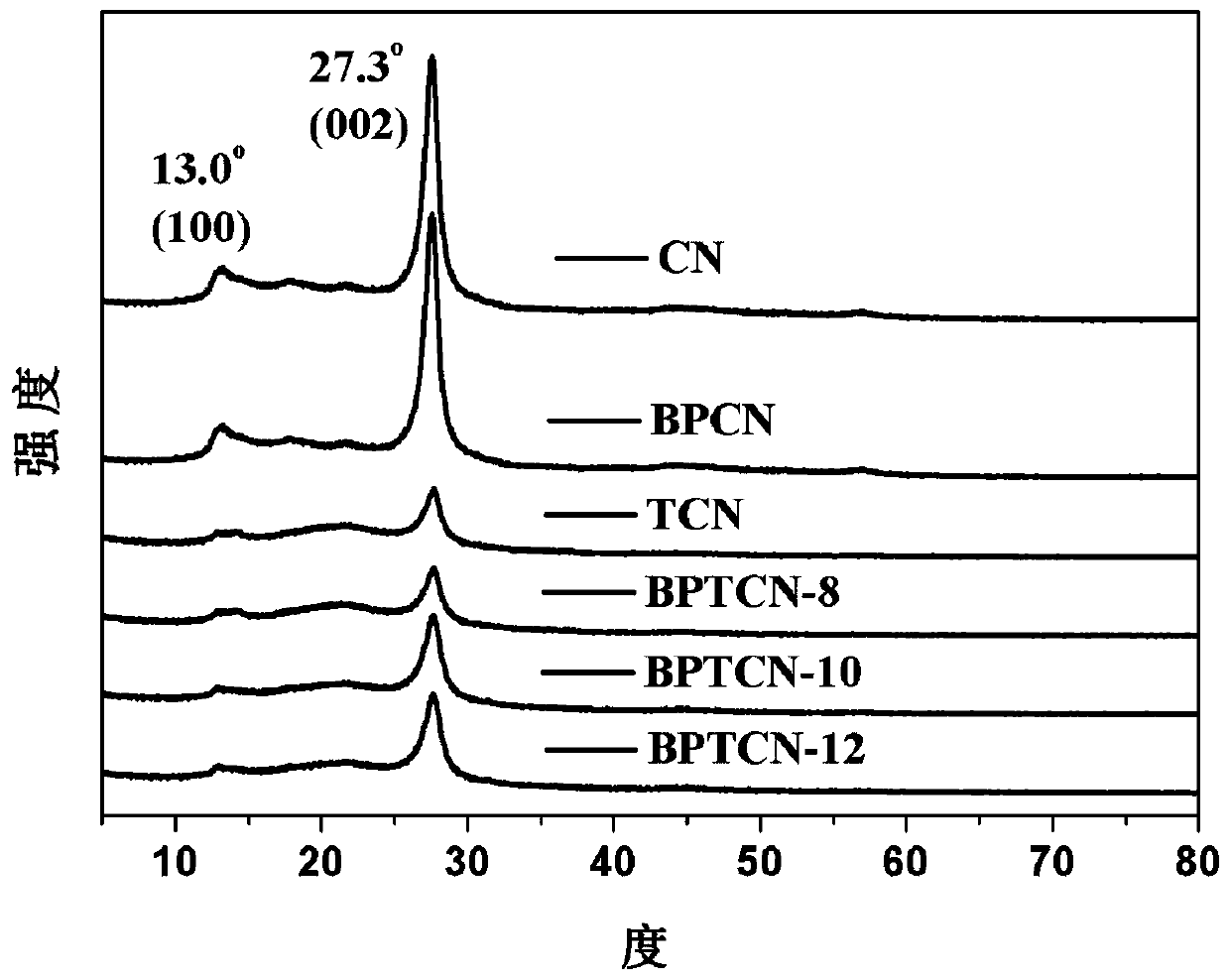

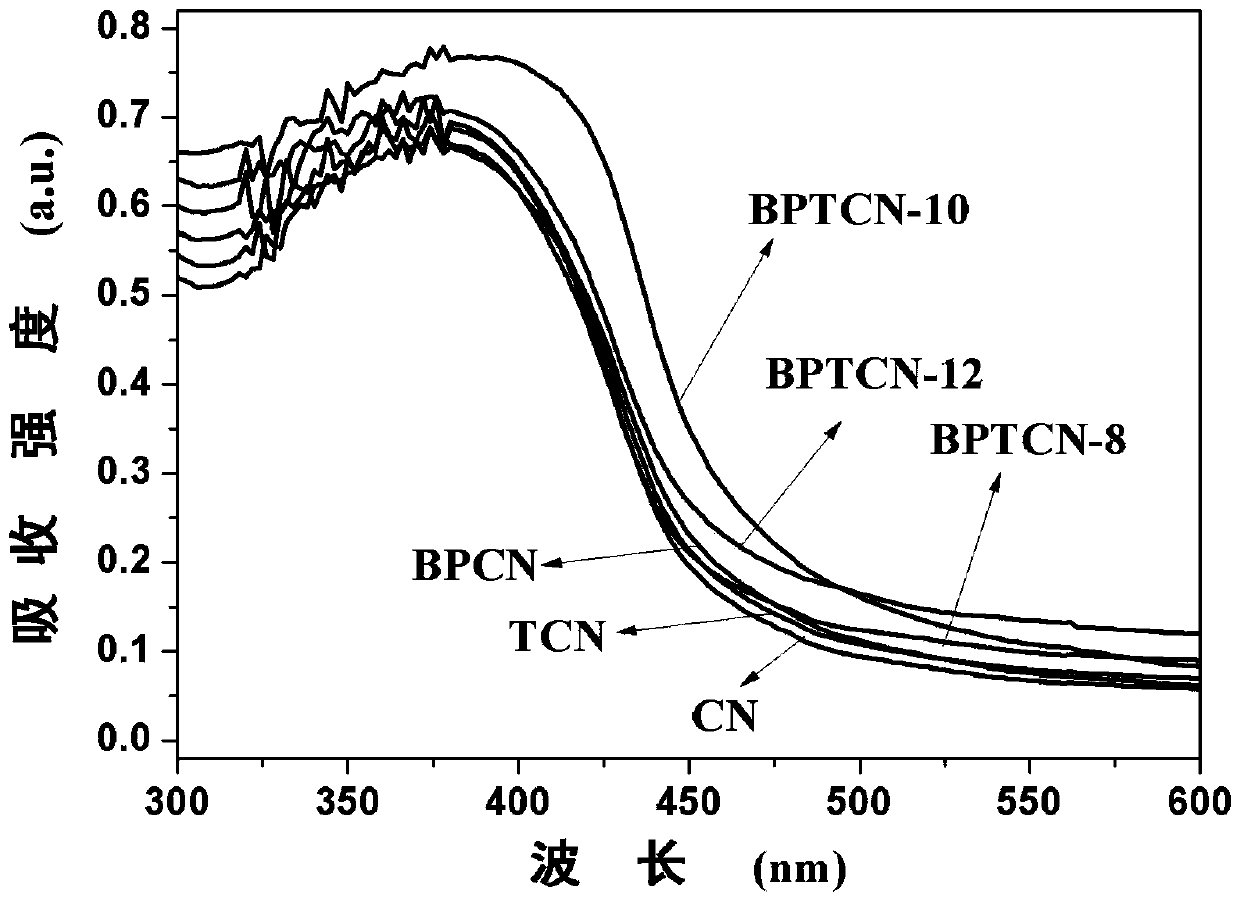

[0037] A zero-dimensional black phosphorous quantum dot / one-dimensional tubular carbon nitride composite photocatalyst includes one-dimensional tubular carbon nitride, and the one-dimensional tubular carbon nitride is modified with zero-dimensional black phosphorous quantum dots.

[0038] A method for preparing the zero-dimensional black phosphorous quantum dots / one-dimensional tubular carbon nitride composite photocatalyst (BPTCN-10) of the above-mentioned embodiment includes the following steps:

[0039] (1) Preparation of one-dimensional tubular carbon nitride:

[0040] (1.1) Take 3g of urea and 1g of melamine, grind, dissolve in 50mL of deionized water, sonicate for 2.5h, and stir at a constant speed of 300r / min for 10h to obtain a uniform mixed solution.

[0041] (1.2) Transfer the mixed solution obtained in step (1.1) to a 100 mL autoclave, keep it at 180°C for 20 hours, rinse with water and ethanol 3 times after natural cooling, filter, and dry at 60°C for 8 hours to obtain the ...

Embodiment 2

[0049] A preparation method of zero-dimensional black phosphorus quantum dots / one-dimensional tubular carbon nitride composite photocatalyst is basically the same as the preparation method in Example 1, except that the zero-dimensional black phosphorus quantum used in the preparation method of Example 2 The volume of the spot solution is 8 mL.

[0050] The zero-dimensional black phosphorous quantum dots / one-dimensional tubular carbon nitride composite photocatalyst prepared in Example 2 is denoted as BPTCN-8.

Embodiment 3

[0052] A preparation method of zero-dimensional black phosphorus quantum dots / one-dimensional tubular carbon nitride composite photocatalyst is basically the same as the preparation method in Example 1, except that: the zero-dimensional black phosphorus quantum used in the preparation method of Example 3 The volume of the spot solution is 12 mL.

[0053] The zero-dimensional black phosphorous quantum dots / one-dimensional tubular carbon nitride composite photocatalyst prepared in Example 3 is denoted as BPTCN-12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com