Dried persimmon and cold-chain treatment method thereof

A processing method and technology for dried persimmons, which are applied in the cold chain processing of dried persimmons and the field of dried persimmons, can solve the problems of loss of deliciousness, rough taste, and difficulty in eating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Processing of dried persimmons: select fresh persimmons that are 7 minutes mature and free from diseases and insect pests, no rot, and no scars, wash them, peel them, put them in a dried persimmon sieve, and dry them in the sun at 32°C for 7 days. Carry out manual kneading for 3 times, then carry out sulfur fumigation with a sulfur dosage of 50g / m3 for 10 minutes, and carry out 2 times of sterilization;

[0027] 2) Quick-freezing: Place the processed persimmons in an environment of -35°C and a wind speed of 3m / s for quick-freezing, so that the dried persimmons pass through the ice crystal formation zone of -1~-5°C within 20 minutes;

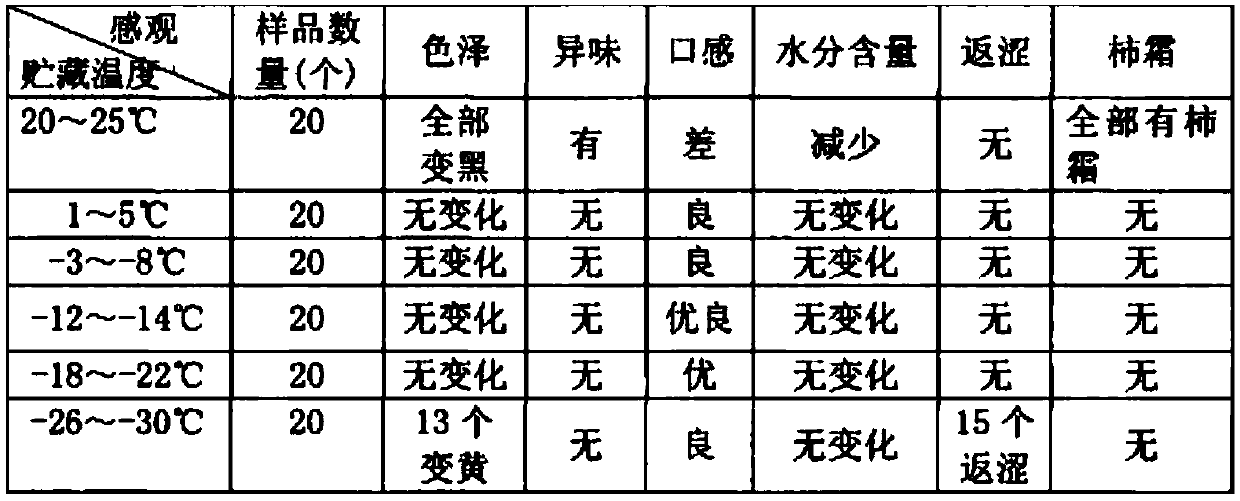

[0028] 3) Storage: Transfer the quick-frozen persimmons to a cold storage at -12°C for storage;

[0029] 4) Transportation: Use a refrigerated and insulated vehicle that can maintain -18°C to transport the dried persimmons, and the loading and unloading time of the dried persimmons should be controlled within 1 hour;

[0030] 5) Sales:...

Embodiment 2

[0032] 1) Processing of persimmons: select 8-point mature fresh persimmons without pests, rot, and scars, wash them and put them into astringent tanks, and fill them with carbon dioxide gas to make the carbon dioxide gas content in the tanks reach 95%. , seal the deastringent tank and remove the astringency for 25 hours; take out the deastringent persimmons, wash them, peel them, and bake them in an environment of 58°C for 12 hours. Bake in the environment for 10 hours, and repeat this 3 times; then use 50g / m3 sulfur fumigation for 5 minutes to sterilize, and the number of times of sterilization is 2 times; pack the sterilized persimmons into packaging bags made of antifreeze composite plastic. 500g / bag;

[0033] 2) Quick-freezing: Place the processed persimmons in an environment of -30°C and a wind speed of 5m / s for quick-freezing, so that the dried persimmons pass through the ice crystal formation zone of -1~-5°C within 30 minutes;

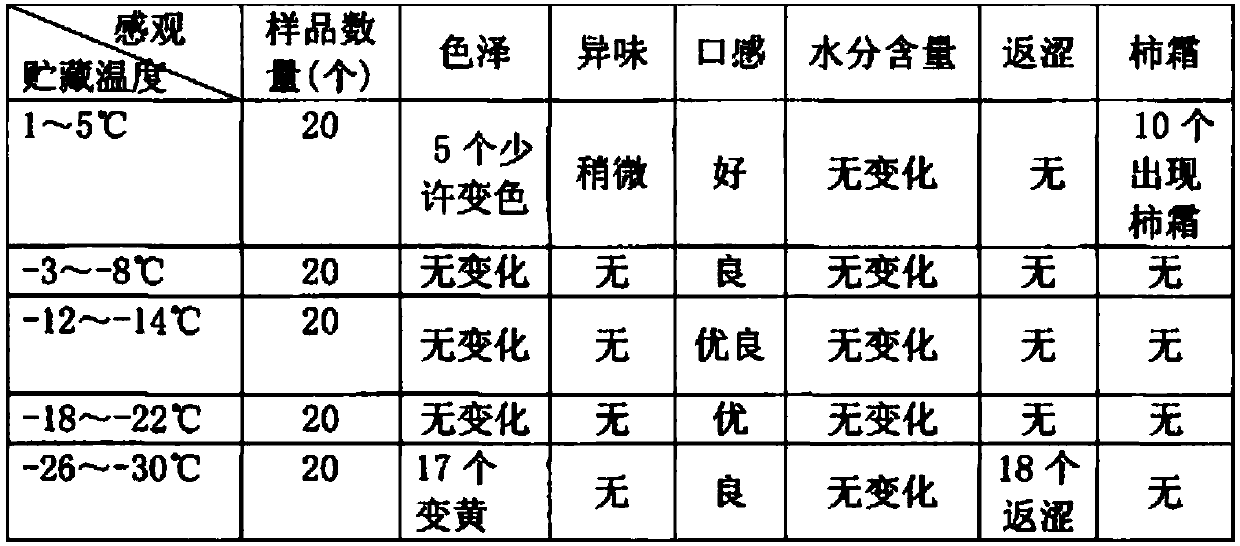

[0034] 3) Storage: transfer the quick-froz...

Embodiment 3

[0038] 1) Persimmon processing: select 80% mature fresh persimmons without pests, rot, and scars, wash them, put them in a solution of 10:1 water and quicklime, soak them for 3 days, take out the persimmons with water Wash and peel the persimmons and place them in a dried persimmon sieve for 25 days in the air at 10°C. During the drying period, knead the persimmons manually once every two days, and then fumigate the persimmons with sulfur at 50g / m3 for 10 minutes. ;

[0039] 2) Quick-freezing: Place the processed persimmons in an environment of -32°C and a wind speed of 4m / s for quick-freezing, so that the dried persimmons pass through the ice crystal formation zone of -1~-5°C within 10 minutes;

[0040] 3) Storage: Transfer the quick-frozen persimmons to a cold storage at -18°C for storage;

[0041] 4) Transportation: Use a refrigerated and insulated vehicle that can maintain -18°C to transport the dried persimmons, and the loading and unloading time of the dried persimmons ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com