Gain medium multiplexed slice hybrid amplification laser and laser output method thereof

A technology of gain medium and output method, which is applied in the direction of lasers, laser components, and the structure/shape of active media, and can solve problems such as increasing system complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

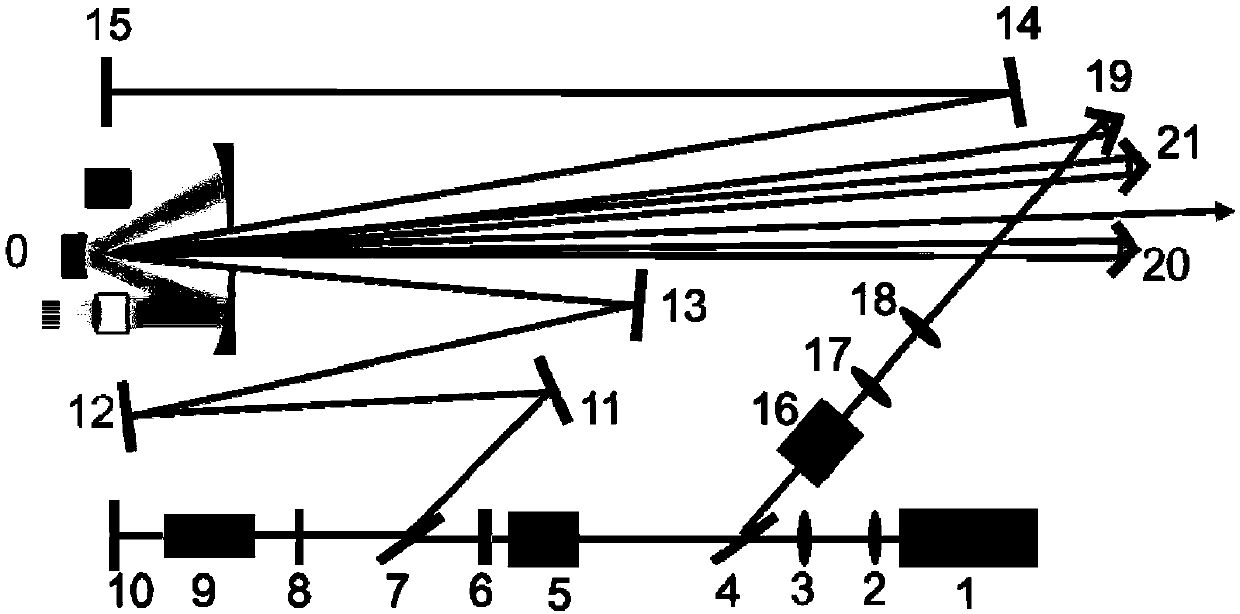

[0026] see figure 1 , a gain medium multiplexed lamella hybrid amplifying laser according to an embodiment of the present invention includes: a seed laser 1 for injecting the amplifier seed light; a first lens 2, a second lens 3, a first polarizer 4, a Faraday Optical rotator 5, half-wave plate 6, second polarizer 7, quarter-wave plate 8, electro-optic crystal 9, second end mirror 10, first folding mirror 11, second folding mirror 12, third folding mirror 13 , the fourth folding mirror 14, the first end mirror 15, 16-optical isolator 16, the third lens 17, the fourth lens 18, the fifth folding mirror 19, the sixth folding mirror 20, and the seventh folding mirror 21.

[0027] The laser beam sequentially passes through the first lens 2, the second lens 3, the first polarizer 4, the Faraday rotator 5, the half-wave plate 6, and the second polarizer 7 to enter the regenerative amplifier, and then passes through the first folding mirror 11 and the second folding mirror. The mirro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com