Fully-automatic screen printer for sheets

A screen printing machine, fully automatic technology, used in screen printing machines, screen printing, printing machines and other directions, can solve the problems of limited adjustable range of suction cups, waste of resources, position deviation, etc., and achieve easy manual maintenance. Convenience, ensure the lifting accuracy, and avoid the effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing of description:

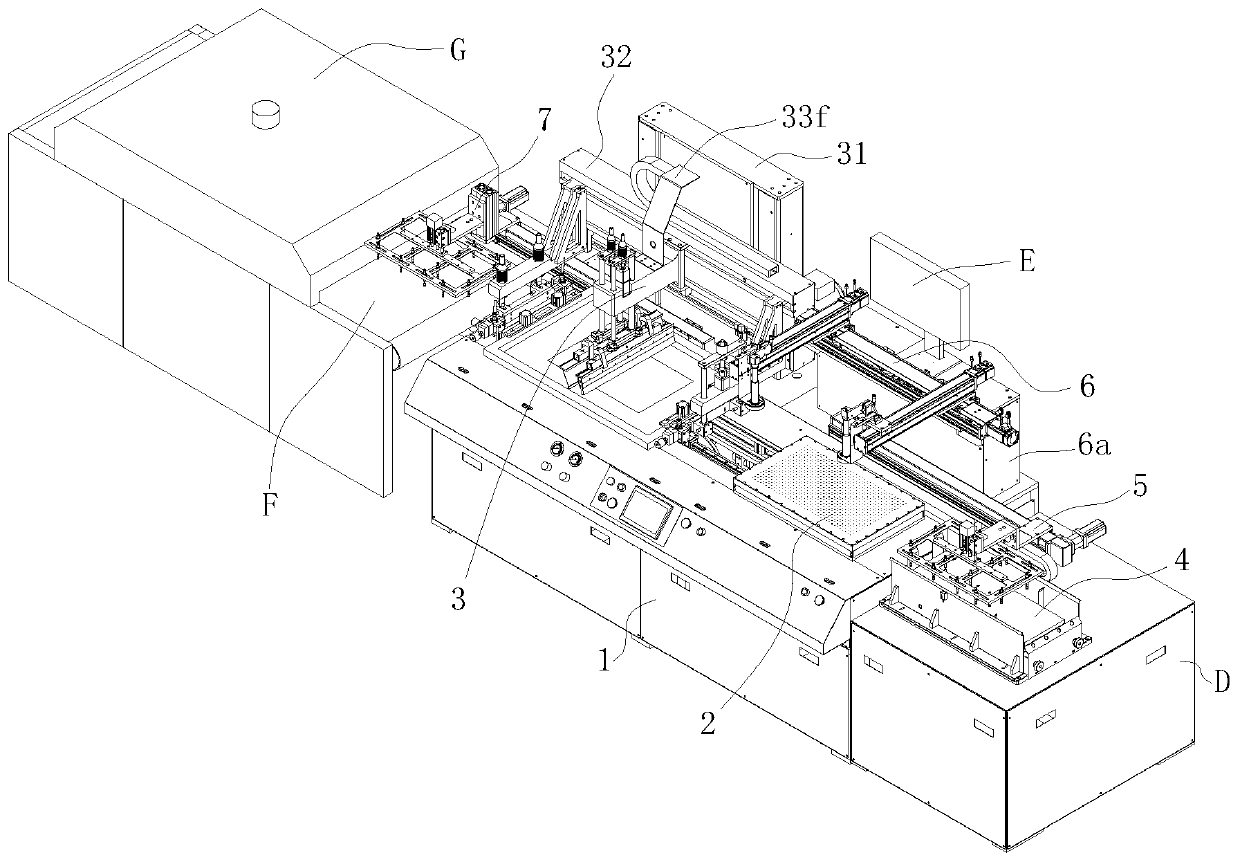

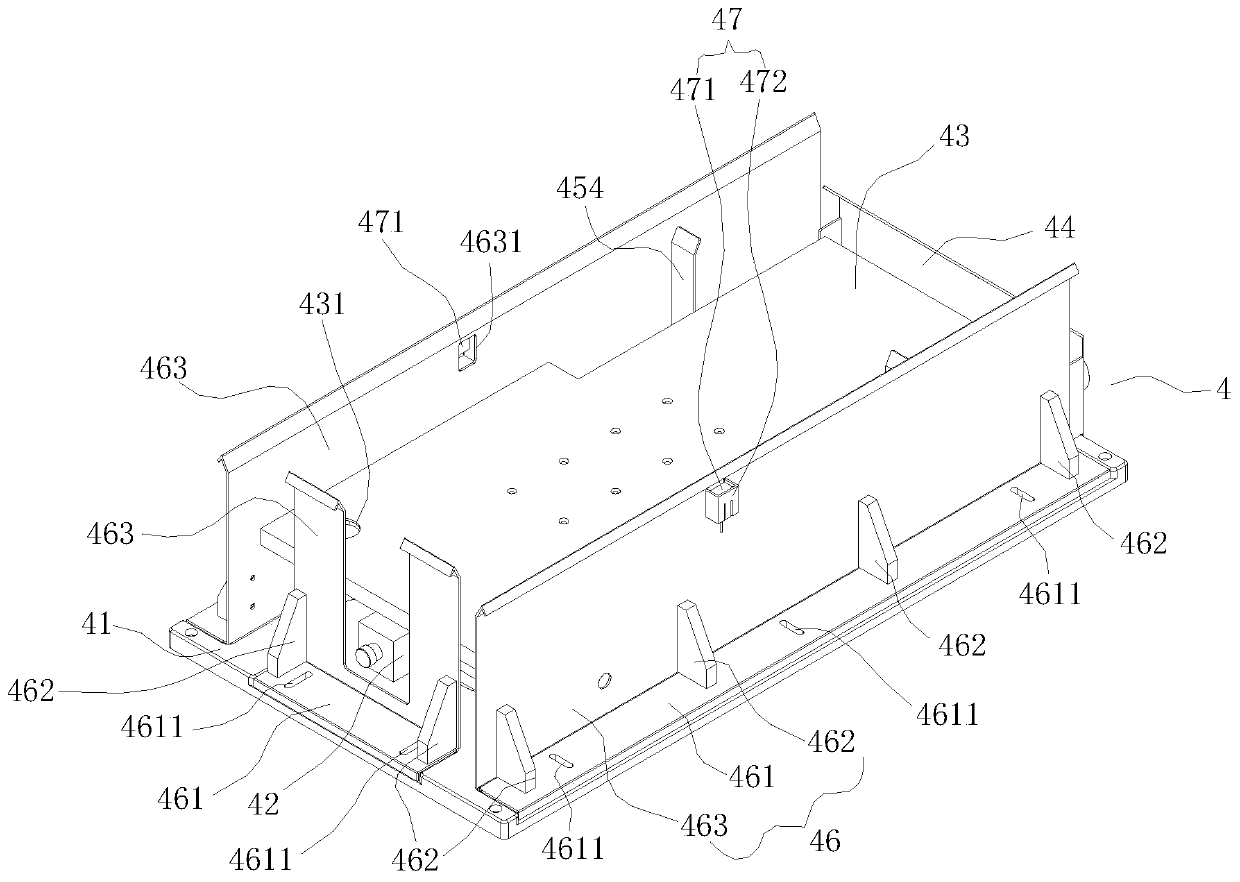

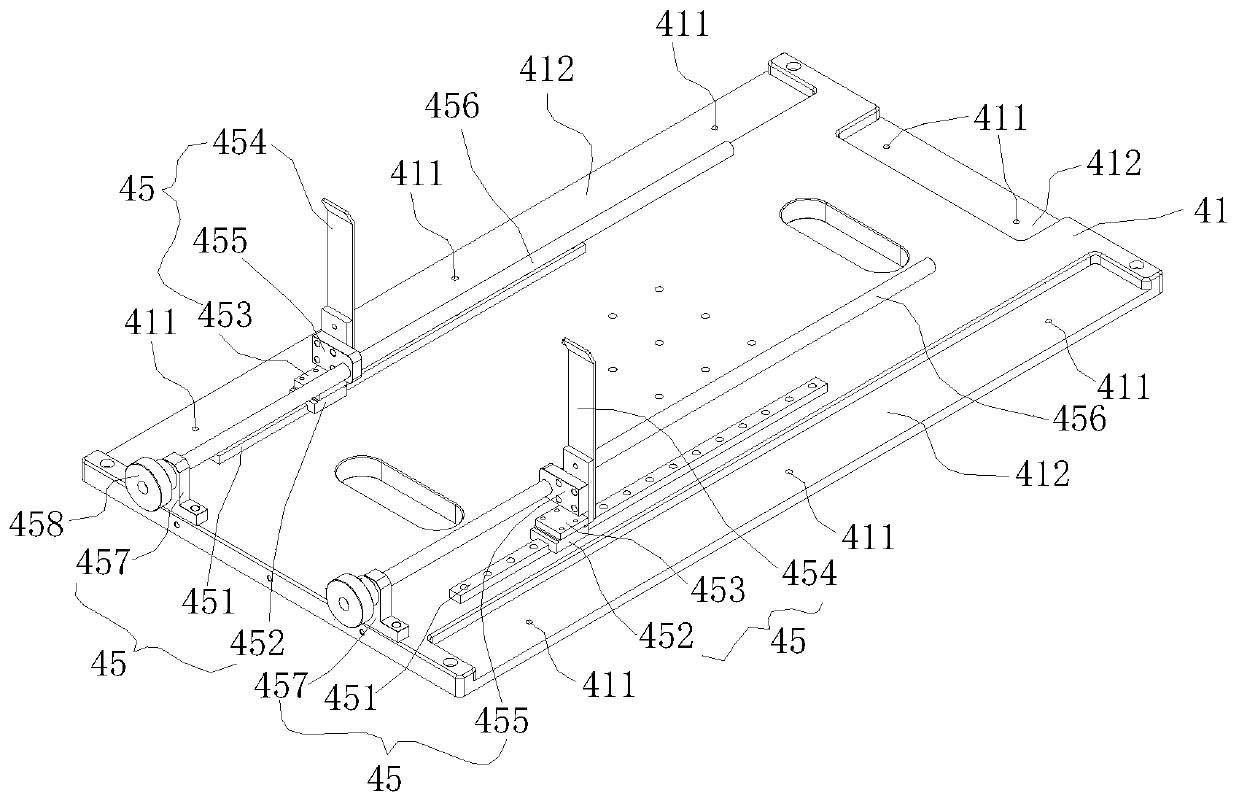

[0045] Such as Figure 1-16 As shown, the present invention relates to a fully automatic sheet material screen printing machine, which includes a conveying unit 2 arranged inside the frame 1, and the conveying unit 2 is used to convey the material to be processed and correct the position of the material to be printed. A printing unit 3 is provided above one end of the frame 1, and the printing unit 3 is used to print the materials to be processed that are conveyed to the preset station by the conveying unit 2. The other end of the frame 1 is provided with a discharge lifting unit 4. The discharge lifting unit 4 is used to supply the materials to be processed and to feed back the material shortage information in time. The end connected to the frame 1 and the discharge lifting unit 4 is provided with a retrieving mechanism 5. The retrieving mechanism 5 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com