Tobacco processing method for cigar

A processing method and technology for cigars, applied in the treatment of tobacco, tobacco, application and other directions, can solve the problems of bitter smoke, strong concentration, dull aroma, etc., to improve sensory quality, reduce smoke concentration, and improve hydrolysis efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

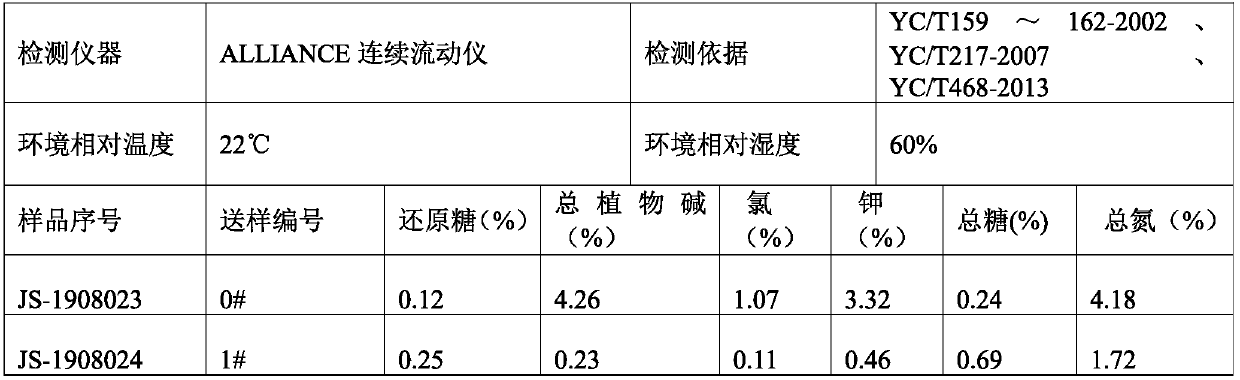

Embodiment 1

[0020] According to the method described in the present invention, at first adopt industrial washing machine to clean and dry the XZ-5 cigar mixed cigarette sheet that our factory product is using, specific requirement is, water level reaches 50% of design capacity, adopts 3 times of cleaning 3 Spin drying mode. The rotating speed of the dehydrating drum needs to exceed 900 rpm for the last spin. Under the solvent temperature of 50°C, add enzyme preparation during the third cleaning, the enzyme preparation formula is cellulase: pectinase: amylase: glucoamylase: catalase: laccase: flavor protease=5:2: 2:20:20:20:20, wherein water is used as diluent to dilute to 100 parts to prepare the enzyme preparation, and the mass ratio of tobacco leaves to enzyme preparation is 100:1. After washing for 1 minute, shake dry and dehydrate. After dehydration, place it in a room with 53°C and 78% relative humidity for 24 hours, and then use a roller feeder to apply sugar and loosen it. Wherei...

Embodiment 2

[0022] According to the method of the present invention, at first the industrial washing machine is used to clean, dry and dehydrate the XZ-5 cigar mixed tobacco sheets used by our factory products. Spin drying mode. The rotating speed of the drying and dehydrating drum needs to reach 900 rpm for the last time. Under the condition of the solvent temperature of 60°C, the enzyme preparation is added during the third cleaning, and the enzyme preparation formula is cellulase: pectinase: amylase: glucoamylase: catalase: laccase: flavor protease=10:5: 5:10:10:10:10, wherein water is used as diluent to dilute to 100 parts to prepare the enzyme preparation, and the mass ratio of tobacco leaves to enzyme preparation is 100:0.5. After washing for 1 minute, spin dry and dehydrate, and place it in a room with 53°C and 78% relative humidity for 12 hours after dehydration, and then use a roller feeder to apply sugar and loosen it. Wherein the added sugar formula is invert sugar: glucose: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com