A Highly Efficient Plasma Gas-Liquid Discharge System

A plasma and gas technology, applied in the direction of plasma, electrical components, etc., can solve the problem of no plasma energy utilization, etc., to achieve the effect of easy disassembly and maintenance, enhanced processing efficiency, and good support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

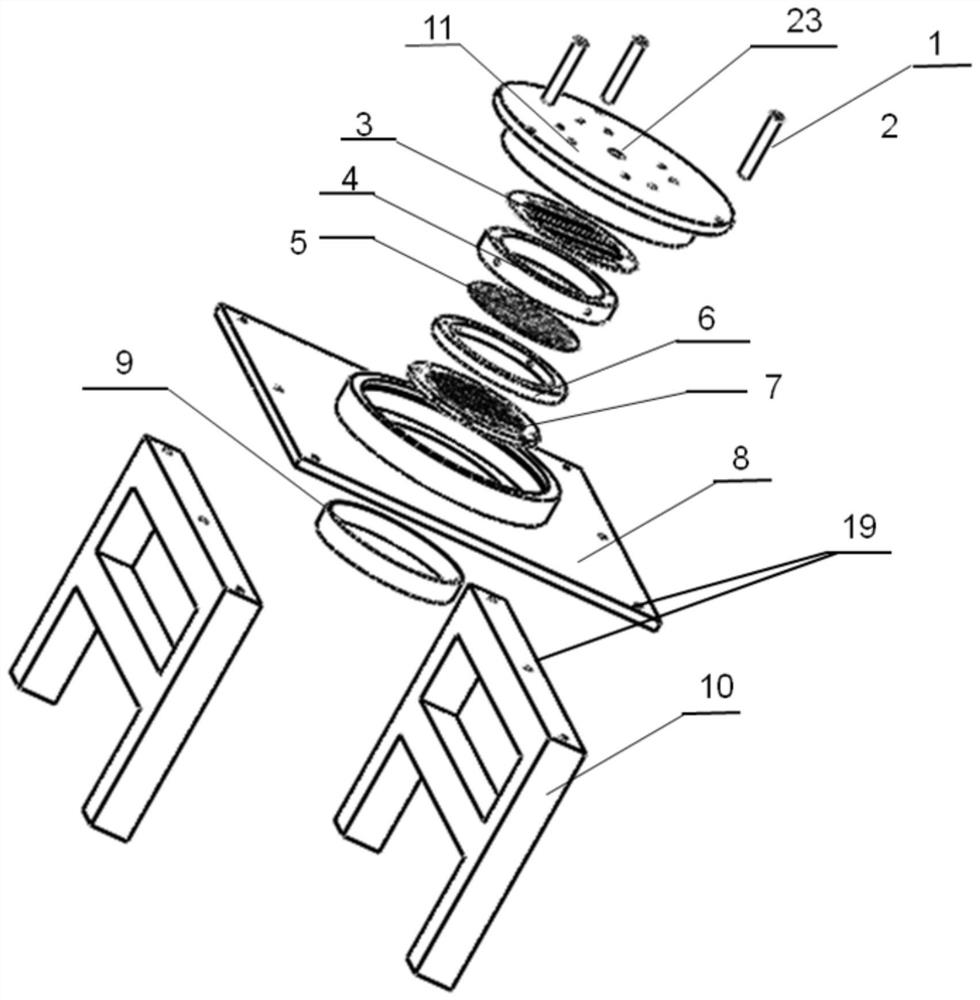

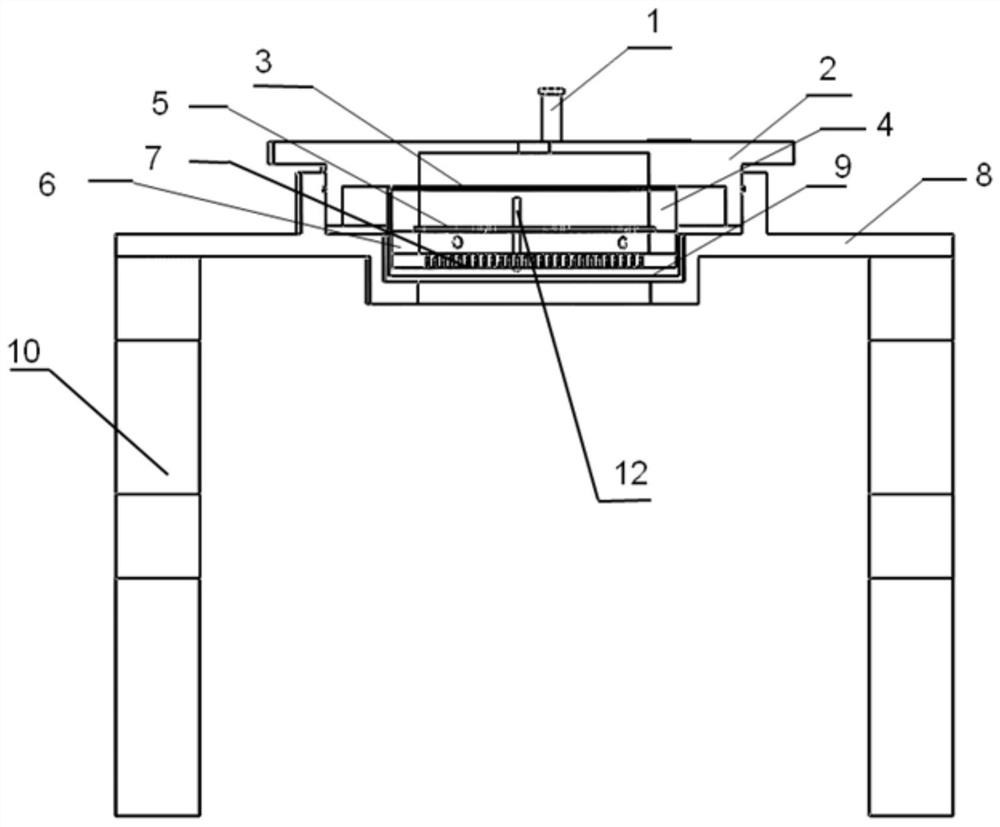

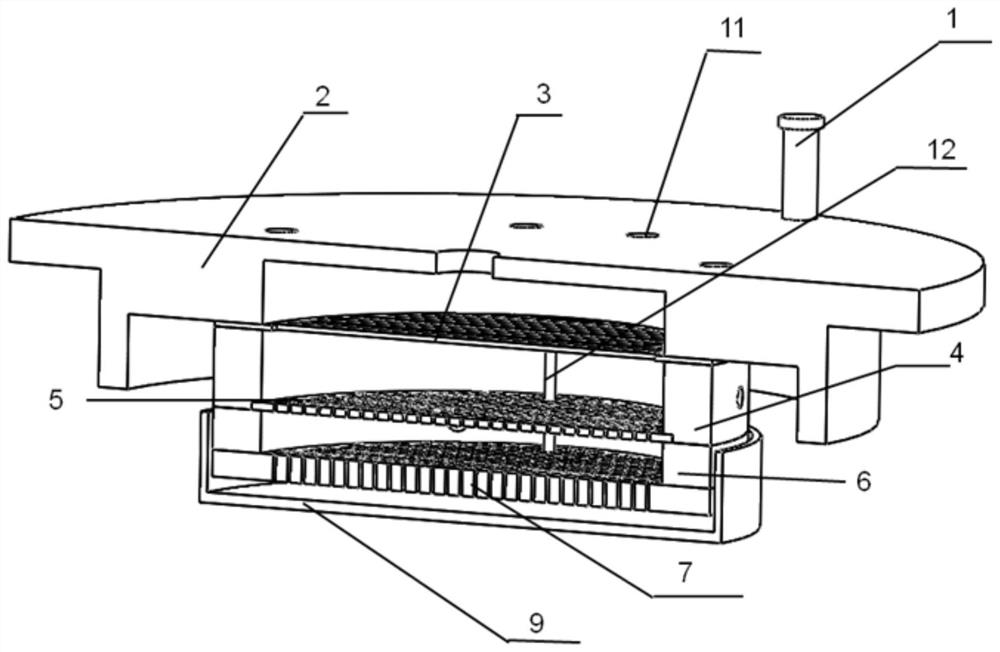

[0075] Such as Figure 1 to Figure 15 As shown, a high-efficiency plasma gas-liquid discharge system includes: a fixed plate I2 arranged sequentially from top to bottom, a dielectric plate I3 with long strip-shaped through holes (this embodiment is referred to as the dielectric plate I3), and a flat dielectric plate Plate II5 (abbreviated as medium plate II5 in this embodiment), flat medium plate III7 (abbreviated as medium plate III7 in this embodiment), medium dish 9, fixed plate II8, fixed plate I2 connected with medium plate I3, The gasket I4, the dielectric plate II5, the gasket II6, and the dielectric plate III7 are connected in sequence, and the dielectric plate II5 is located between the gasket I4 and the gasket II6. The center of the fixed plate II8 is provided with a medium plate 9, and the medium plate 9 is located between the medium plate III7 and the fixed plate II8; the fixed plate I2 is connected with the medium plate I1, the washer I4, the medium plate II5, Ga...

Embodiment 2

[0078] Such as Figure 1 to Figure 18As shown, a high-efficiency plasma gas-liquid discharge system includes: a fixed plate I2 arranged in sequence from top to bottom, a dielectric plate I13 with a circular through hole (this embodiment is referred to as the dielectric plate I13), and a dielectric plate I13 with an integrated structure. Plate II14 (abbreviated as medium plate II14 in this embodiment), medium plate III15 with boss structure (abbreviated as medium plate III15 in this embodiment), medium plate 9, fixed plate II8, and medium plate II14 with integrated structure is a gasket Ⅰ4, gasket Ⅱ6 and flat dielectric plate II constitute an integrated structure, and the flat dielectric plate Ⅱ and dielectric plate Ⅱ5 are located between gasket Ⅰ4 and gasket Ⅱ6. The fixed plate I2 is sequentially connected with the medium plate I3, the washer I4, the medium plate II5, the washer II6 and the medium plate III7 through the set screw 11. The center of the fixed plate II8 is provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com