An auxiliary heat preservation device for microwave sintering

A heat preservation device and microwave sintering technology, applied in the field of microwave sintering, can solve the problems of affecting the sintering process, high replacement cost, crucible collapse, etc., and achieve the effects of good wave absorption performance, easy replacement and convenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

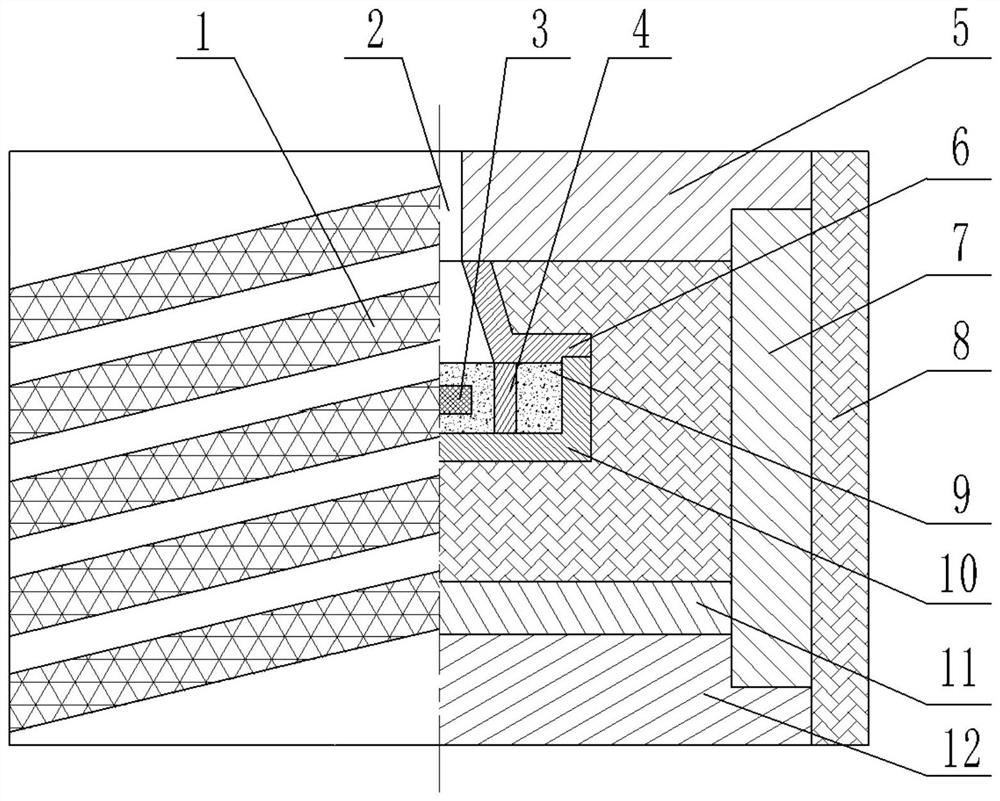

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

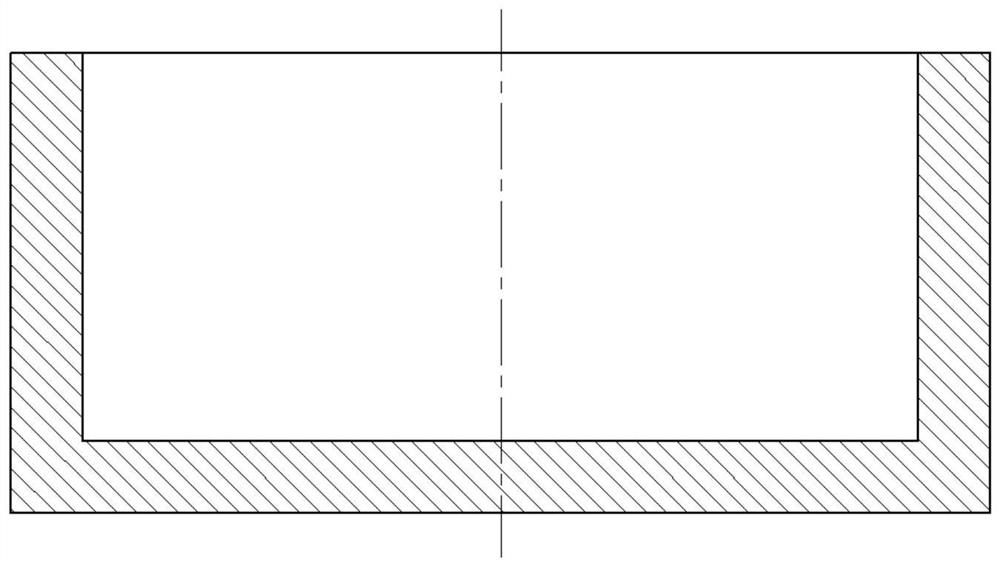

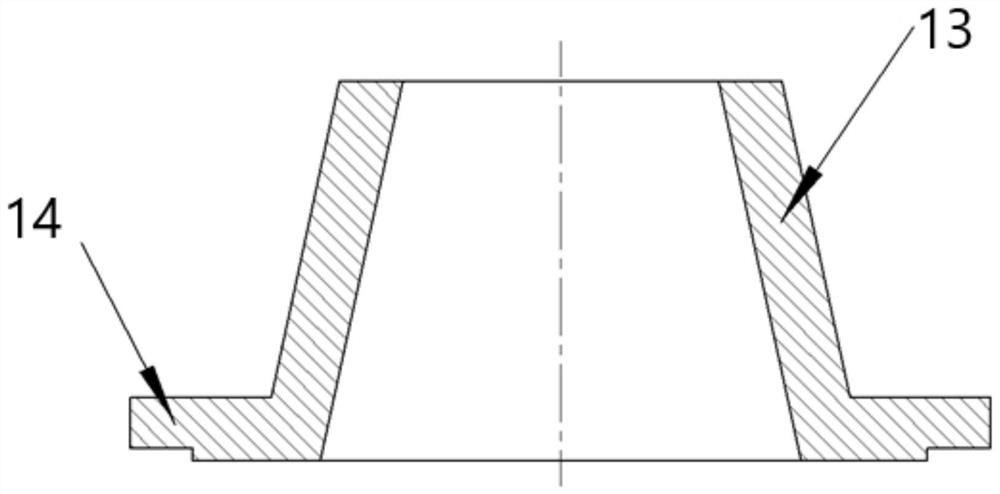

[0030] Such as Figure 1-3 As shown, an auxiliary heat preservation device for microwave sintering, including glass fiber high temperature belt 1, temperature measuring hole 2, sintered sample 3, boron nitride ring 4, mullite fiber box upper cover plate 5, boron nitride Crucible cover 6, mullite fiber box body 7, polycrystalline mullite high temperature fiber cotton layer 8, silicon carbide powder 9, boron nitride crucible, mullite fiber board 11, mullite fiber box lower cover plate 12.

[0031] In the device, the upper cover plate 5 of the mullite fiber box, the lower cover plate 12 of the mullite fiber box and the box body 7 of the mullite fiber box form a closed box body, and a circle of polycrystalline mullite high temperature is wrapped on the side of the box body. Fiber cotton layer 8 is wrapped with one deck glass fiber high-temperature belt 1 on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| processing temperature | aaaaa | aaaaa |

| processing temperature | aaaaa | aaaaa |

| processing temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com