Exhaust air catalytic oxidation device utilizing supercritical CO2 solar heat collecting and storing for heating

A technology of solar heat collection and catalytic oxidation, applied in solar collectors, solar heating systems, solar collector controllers, etc., can solve the problem of low electric power in the power generation system, increased use of external electric energy, secondary waste of gas energy, etc. problems, to achieve the effect of compact equipment structure, high utilization rate, and reduction of nitrogen oxides generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

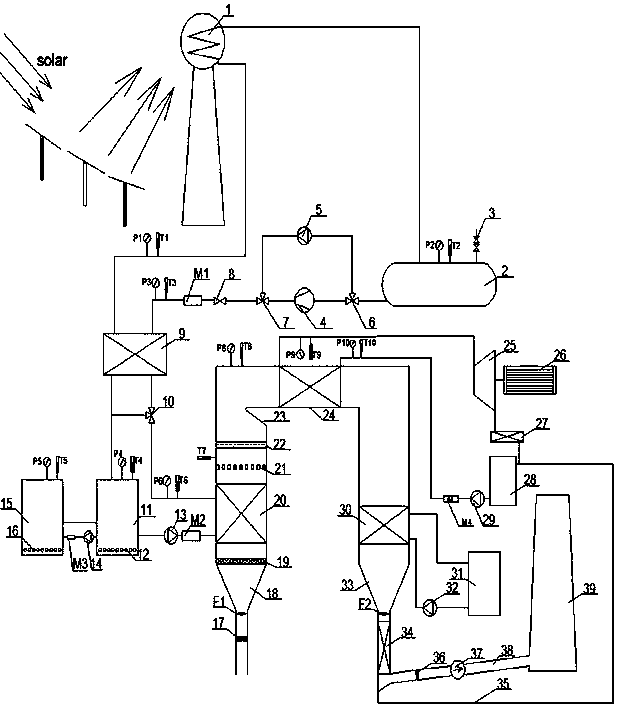

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

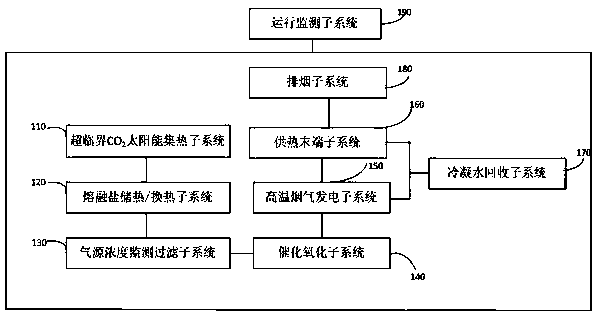

[0030] Such as figure 1 As shown, the present invention provides a method using supercritical CO 2 The exhaust air catalytic oxidation device heated by solar heat collection and thermal storage, including supercritical CO 2 Solar heat collection subsystem 110, molten salt heat storage / heat exchange subsystem 120, air source concentration monitoring and filtration subsystem 130, catalytic oxidation subsystem 140, high temperature flue gas power generation subsystem 150, heat supply terminal subsystem 160, condensed water Recovery subsystem 170 , smoke exhaust subsystem 180 and operation monitoring subsystem 190 .

[0031] Among them, supercritical CO 2 The solar collector subsystem 110 uses supercritical CO 2 Tower-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com