Construction method of prefabricated support structure for tunnels in alpine regions

A supporting structure and construction method technology, applied in the direction of tunnels, tunnel linings, shaft equipment, etc., can solve the problems of time consumption, many processes, and influence on the progress of construction, so as to reduce the number of processes, improve the working environment, and improve the construction efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

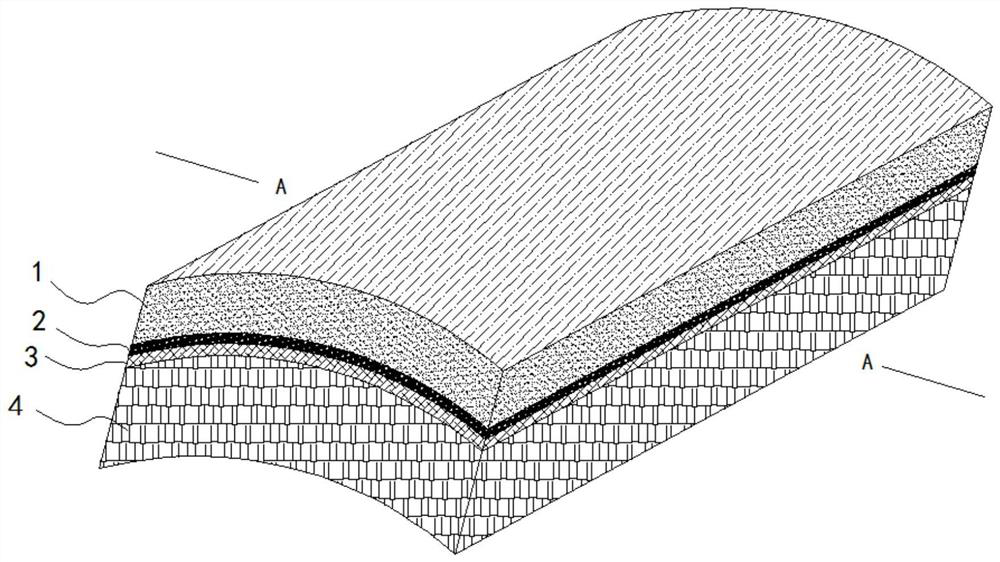

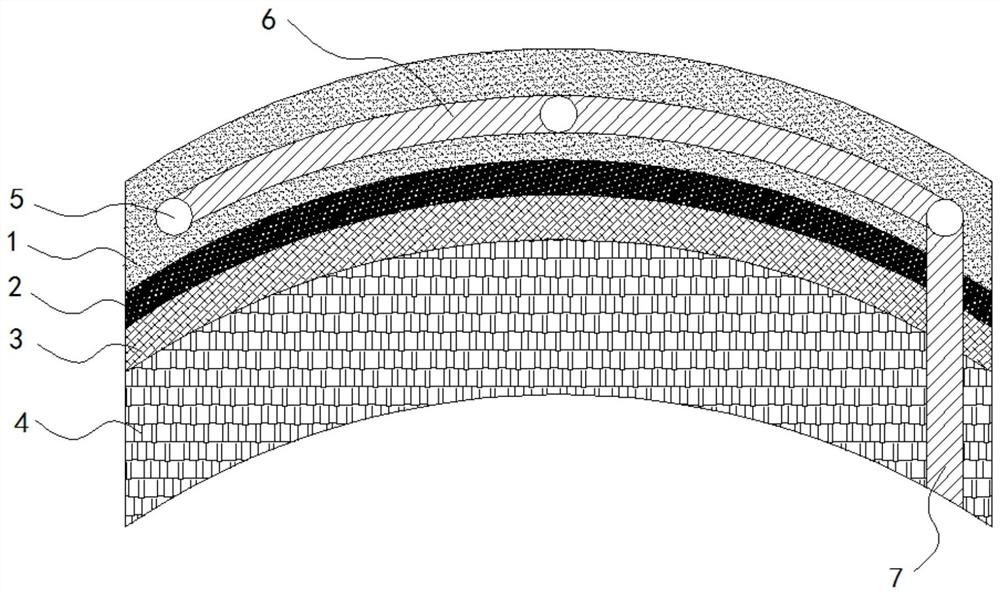

[0043] A construction method for a prefabricated support structure of a tunnel in an alpine region, comprising the following steps:

[0044] 1) Manufacture of permeable concrete components: After the permeable pipes are preset in the permeable concrete component molds, sand-free concrete is used to pour into block structures to obtain permeable concrete components. It protrudes from the front of the permeable concrete member; the mass ratio of sand-free concrete is: cement: crushed stone: water = 1:4.53:0.23, and it is processed in a factory-style block. use 10HPB300 steel bars are used as connecting bars with a spacing of 20cm×20cm.

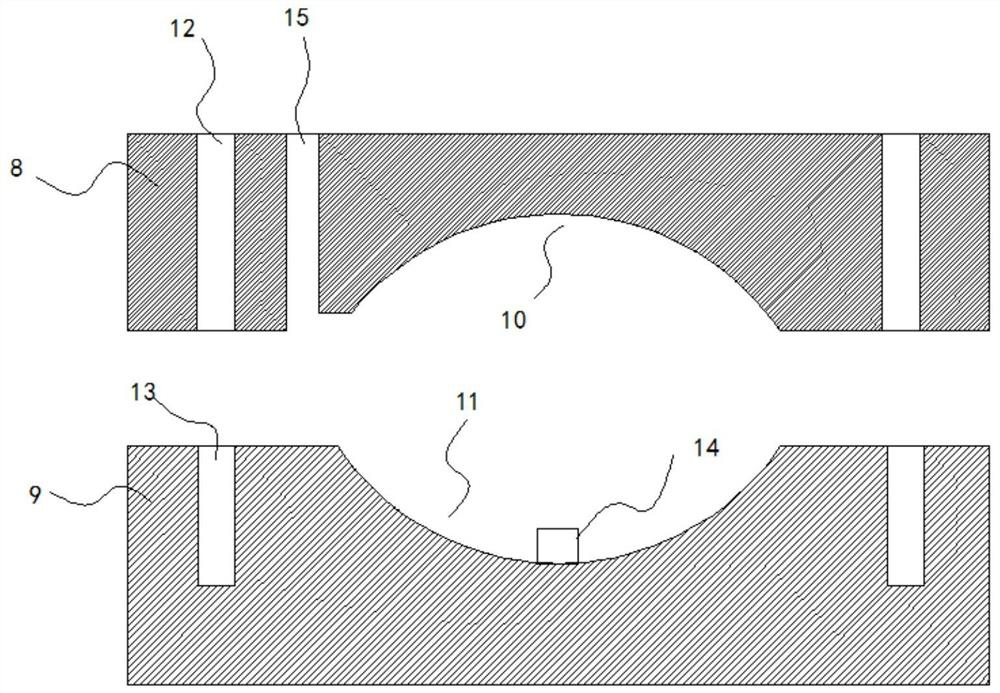

[0045] 2) The permeable concrete component and the supporting concrete layer are poured together to form a splicing block: using factory centralized processing, the permeable concrete component is put into the forming mold as the bottom layer, and then a layer of waterproof material is sequentially laid on the front of the permeable concrete c...

Embodiment 2

[0049] A construction method for a prefabricated support structure of a tunnel in an alpine region, comprising the following steps:

[0050] 1) Manufacture of permeable concrete components: After the permeable pipes are preset in the permeable concrete component molds, sand-free concrete is used to pour into block structures to obtain permeable concrete components. It protrudes from the front of the permeable concrete member; the mass ratio of sand-free concrete is: cement: crushed stone: water = 1:4.53:0.23, and it is processed in a factory-style block. use 10HPB300 steel bars are used as connecting bars with a spacing of 20cm×20cm.

[0051] 2) The permeable concrete component and the supporting concrete layer are poured together to form a splicing block: using factory centralized processing, the permeable concrete component is put into the forming mold as the bottom layer, and then a layer of waterproof material is sequentially laid on the front of the permeable concrete c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com