Preparation method of organic-inorganic hybrid halide micro-nano tubes

A technology of micro-nanotubes and halides, which is applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of zero-dimensional organic-inorganic hybrid halide controllable morphology micro-nanotubes that have not been reported, and achieve the goal of overcoming the morphology Uncontrollable size, very high confinement effect, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 (C 5 h 7 N 2 ) 2 ZnBr 4 Preparation of micro-nanotubes

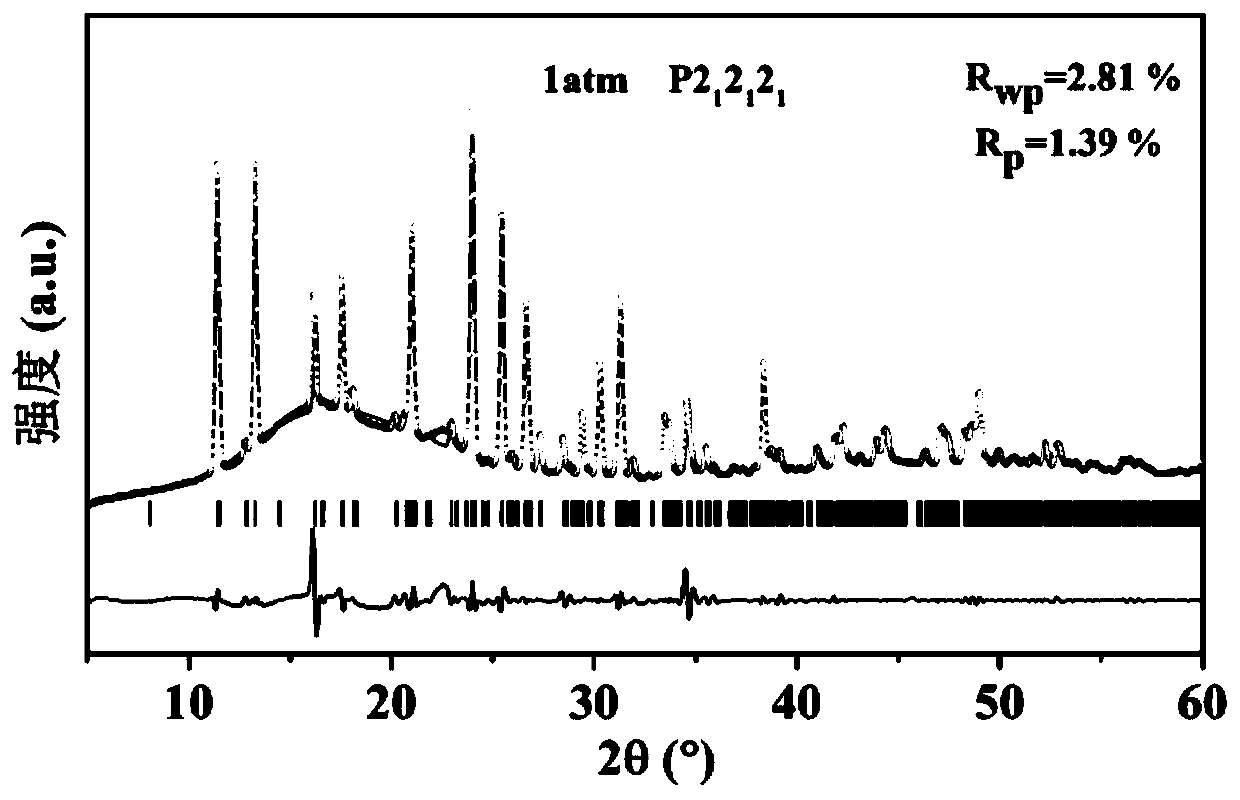

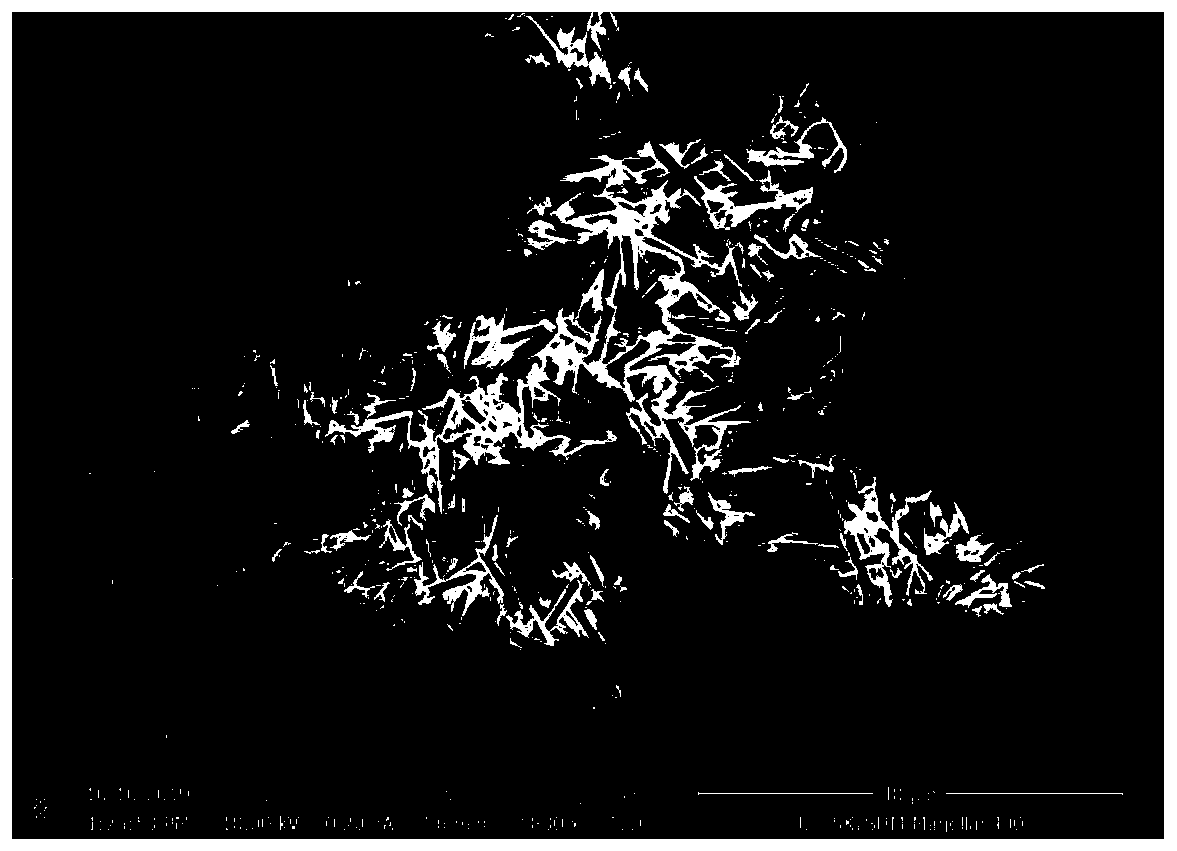

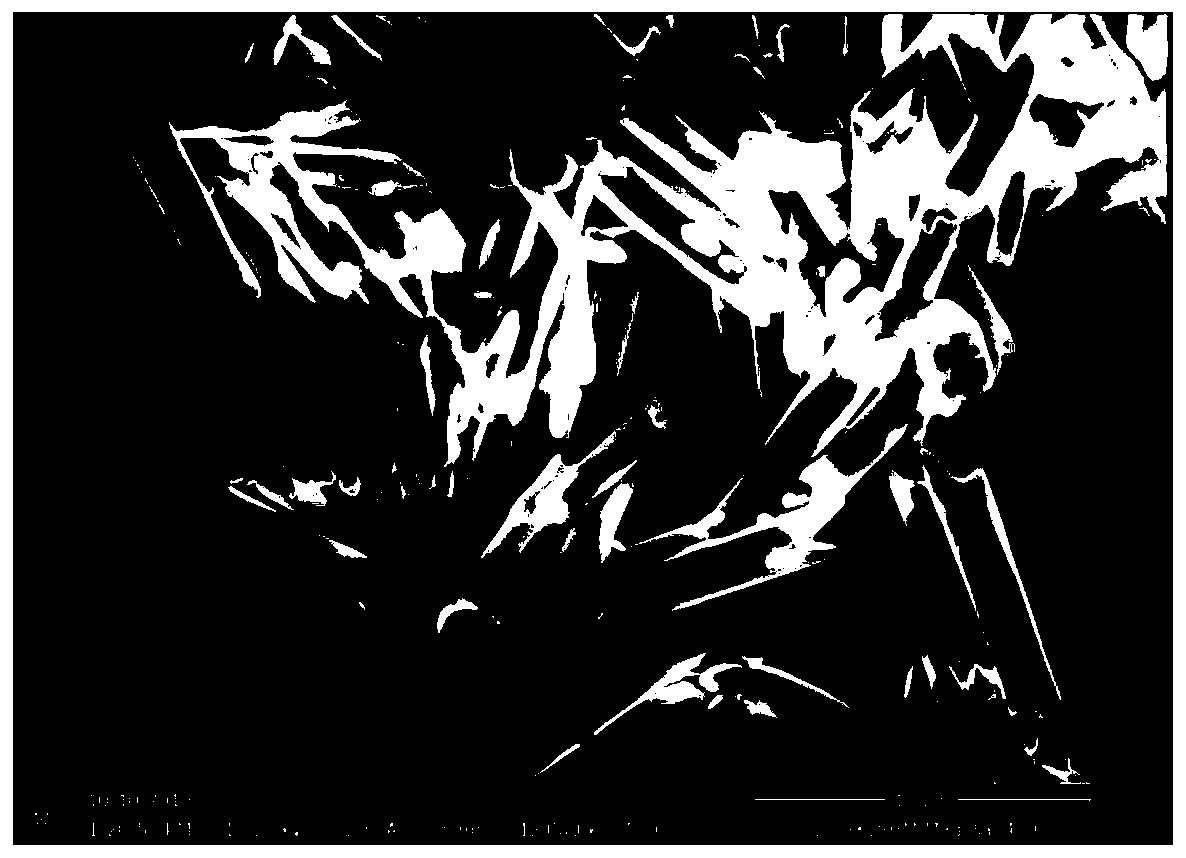

[0040] Put 0.1mmol of anhydrous zinc acetate, 0.2mmol of 4-aminopyridine, 10ml of octadecene, 2.0mL of oleic acid and 0.2mL of oleylamine into a three-necked bottle and accompanied by strong magnetic stirring, under the protection of nitrogen The temperature was gradually raised to 110°C and kept for 1 hour. The solution was a light yellow clear solution. Then the temperature was naturally lowered to 80°C and kept for 30 minutes. Added 0.1 mL of bromotrimethylsilane with a concentration of 98%, the solution quickly turned into a white suspension. show (C 5 h 7 N 2 ) 2 ZnBr 4 micronanotube formation. Take it out after 8 minutes and wash the sample twice with toluene. Such as figure 1 As shown, (C 5 h 7 N 2 ) 2 ZnBr 4 The X-ray diffraction pattern (XRD) of the micro-nanotubes fits very well with the theoretically calculated XRD. figure 2 Scanning electron micrographs with a scale bar ...

Embodiment 2

[0041] Embodiment 2 reduces temperature and is 60 ℃ (C 5 h 7 N 2 ) 2 ZnBr 4 Preparation of micro-nanotubes

[0042] Put 0.1mmol of anhydrous zinc acetate, 0.2mmol of 4-aminopyridine, 10ml of octadecene, 2.0mL of oleic acid and 0.2mL of oleylamine into a three-necked bottle and accompanied by strong magnetic stirring, under the protection of nitrogen The temperature was gradually raised to 110°C and kept for 1 hour. The solution was a light yellow clear solution. Then the temperature was naturally lowered to 60°C and kept for 30 minutes. Added 0.1 mL of bromotrimethylsilane with a concentration of 98%, the solution gradually turned into a white suspension. show (C 5 h 7 N 2 ) 2 ZnBr 4 micronanotube formation. Take it out after 8 minutes and wash the sample twice with toluene. Figure 5 The scanning electron micrographs with a scale bar of 50 μm are more uniform in size compared with those at 80°C. Figure 6~7 Scanning electron micrographs with scale bars of 10 μm an...

Embodiment 3

[0043] Embodiment 3 increases the amount of oleylamine to be 0.5mL (C 5 h 7 N 2 ) 2 ZnBr 4 Preparation of micro-nanotubes

[0044] Put 0.1mmol of anhydrous zinc acetate, 0.2mmol of 4-aminopyridine, 10ml of octadecene, 2mL of oleic acid and 0.5mL of oleylamine into a three-necked flask accompanied by strong magnetic stirring, and bring the temperature under the protection of nitrogen. Gradually rise to 110°C and keep it for 1h, the solution is a light yellow clear solution, then naturally cool down to 80°C, keep it for 30min, add 0.1mL trimethylbromosilane with a concentration of 98%, the solution quickly turns into a white suspension, showing (C 5 h 7 N 2 ) 2 ZnBr 4 micronanotube formation. Take it out after 8 minutes and wash the sample twice with toluene. Such as Figure 8-9 As shown, the product changes from micro-nanotubes to ellipsoidal nanotubes with an increase in the amount of oleylamine, and the average diameter of the ellipsoidal tubes is 500 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com