Flame-retardant anticorrosive coating material for outdoor power equipment, and preparation method thereof

A technology for anti-corrosion coatings and electrical equipment, applied in anti-corrosion coatings, fire-retardant coatings, anti-fouling/underwater coatings, etc., which can solve the problems that anti-corrosion coatings do not have flame retardant properties, are difficult to meet the requirements of anti-corrosion durability, weather resistance, and lack anti-fouling. , to achieve good interface phenomenon, good application prospects, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

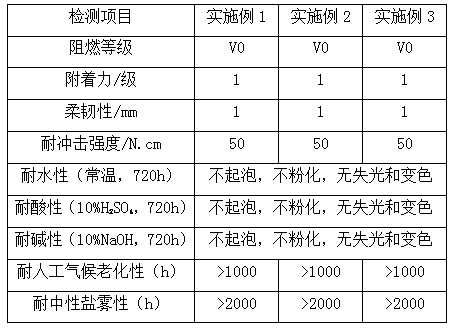

Embodiment 1

[0023] A flame-retardant anti-corrosion coating for outdoor power equipment, made of the following raw materials in parts by weight:

[0024] 20 parts of phosphorus-containing phenolic resin, 1 part of fluorosilicon polymer three-proof additive, 15 parts of epoxy resin, 8 parts of polyamide resin, 5 parts of polymethyl acrylate, 6 parts of nano-silica, 1 part of nano-titanium dioxide, nano 8 parts of zinc oxide, 2 parts of silane coupling agent, and 15 parts of solvent.

[0025] The phosphorus-containing phenolic resin is a highly flame-retardant phenolic resin formed by reacting diphenylphosphine and its derivatives with phenol-type phenolic resin or bisphenol A-type phenolic resin at 125°C as a flame retardant, containing The amount of phosphorus is 3-5%, and the flame retardant performance reaches V0 level.

[0026] The terminal group of the polyamide resin is a carboxyl group, and the molecular weight of the polyamide resin is 3000-6000 g / mol.

[0027] The solvent is a m...

Embodiment 2

[0033] A flame-retardant anti-corrosion coating for outdoor power equipment, made of the following raw materials in parts by weight:

[0034] 25 parts of phosphorus-containing phenolic resin, 3 parts of fluorosilicon polymer three-proof auxiliary agent, 20 parts of epoxy resin, 10 parts of polyamide resin, 7 parts of polymethyl acrylate, 8 parts of nano-silica, 3 parts of nano-titanium dioxide, nano Zinc oxide 10 parts, silane coupling agent 4 parts, solvent 20 parts.

[0035] The phosphorus-containing phenolic resin is a highly flame-retardant phenolic resin formed by reacting diphenylphosphine and its derivatives with phenol-type phenolic resin or bisphenol A-type phenolic resin at 125°C as a flame retardant, containing The amount of phosphorus is 3-5%, and the flame retardant performance reaches V0 level.

[0036] The terminal group of the polyamide resin is a carboxyl group, and the molecular weight of the polyamide resin is 3000-6000 g / mol.

[0037] The solvent is a mix...

Embodiment 3

[0043] A flame-retardant anti-corrosion coating for outdoor power equipment, made of the following raw materials in parts by weight:

[0044] 30 parts of phosphorus-containing phenolic resin, 5 parts of fluorosilicon polymer three-proof auxiliary agent, 25 parts of epoxy resin, 12 parts of polyamide resin, 8 parts of polymethyl acrylate, 9 parts of nano-silica, 4 parts of nano-titanium dioxide, nano Zinc oxide 12 parts, silane coupling agent 6 parts, solvent 25 parts.

[0045] The phosphorus-containing phenolic resin is a highly flame-retardant phenolic resin formed by reacting diphenylphosphine and its derivatives with phenol-type phenolic resin or bisphenol A-type phenolic resin at 125°C as a flame retardant, containing The amount of phosphorus is 3-5%, and the flame retardant performance reaches V0 level.

[0046] The terminal group of the polyamide resin is a carboxyl group, and the molecular weight of the polyamide resin is 3000-6000 g / mol.

[0047] The solvent is a mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com