Infrared glass and its preparation method

A technology of infrared glass and photoresist layer, which is applied in the direction of instruments, optics, optical filters, etc., can solve the problems of affecting the process, large warpage of infrared glass sheets, high cost of magnetron sputtering coating, etc., to achieve improved thickness consistency , Improve process flexibility, reduce the effect of a coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. The advantages and features of the present invention will become more apparent from the following description. It should be noted that the accompanying drawings are in a very simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of explaining the embodiments of the present invention.

[0038] An embodiment of the present invention provides an infrared glass, comprising:

[0039] a substrate having opposing first and second surfaces;

[0040] A filter photoresist layer is formed on the first surface,

[0041] A coating layer is formed on the second surface.

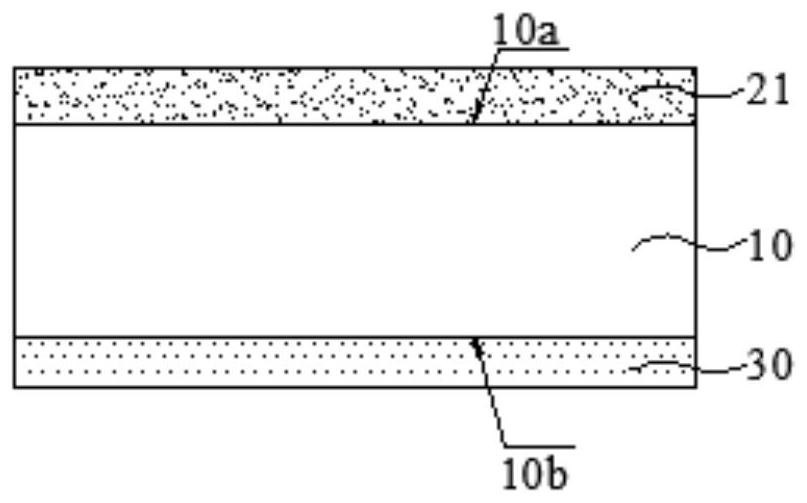

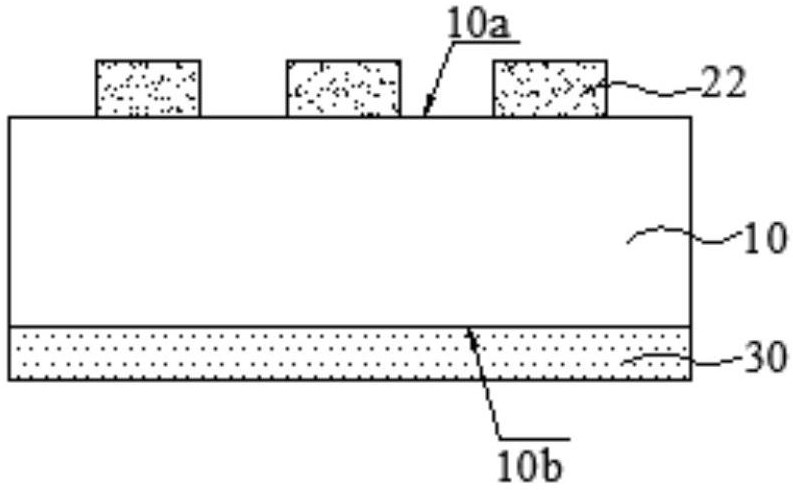

[0042] Specifically, as figure 1 and figure 2 As shown, the substrate 10 has opposing first and second surfaces 10a and 10b. The substrate may be a glass substrate or an optical-grade light-transmitting substrate. The substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com