Recovery method and recovery system for PTA refined mother liquor

A mother liquor recovery and mother liquor technology, applied in chemical instruments and methods, neutralized water/sewage treatment, separation/purification of carboxylic acid compounds, etc., can solve the problems of high investment, large amount of ion exchange resin, large amount of solid waste, etc. , to achieve the effect of reducing investment and operating costs, increasing ion concentration, and reducing total emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] The temperature of the refined mother liquor drops to 80°C after flash evaporation. At this time, the pH in the mother liquor is 3, the content of TA is 50ppm, the content of PT acid is 60ppm, the content of acetic acid is 2000ppm, the content of cobalt ion is 2ppm, the content of manganese ion is 3ppm, and the content of iron ion is 0.5ppm. The sodium ion content is 10ppm, add NaOH to adjust the pH to 3.3, pump it into the ultrafiltration system, and use a circulating pump to circulate it to filter and concentrate, and the concentrated liquid is discharged to the concentrated liquid tank with stirring for recycling.

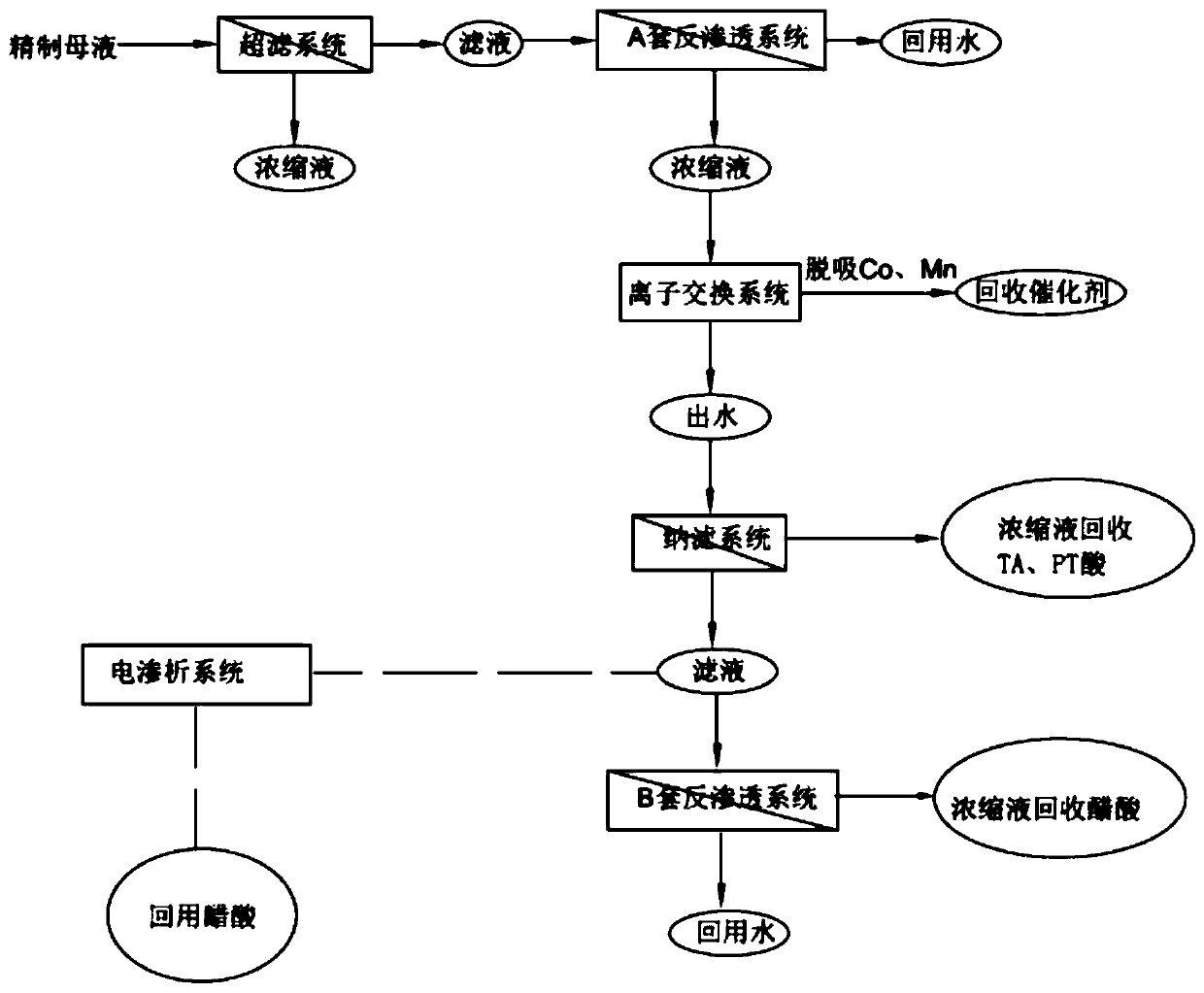

[0077] The filtrate of the ultrafiltration system enters the ultrafiltration filtrate tank, and then is pumped into the A set of reverse osmosis water recovery system. The ultrafiltration filtrate is intercepted and concentrated by a set of reverse osmosis (RO). The amount of filtrate passing through the reverse osmosis membrane is about 4 / 5 of the influen...

Embodiment 2

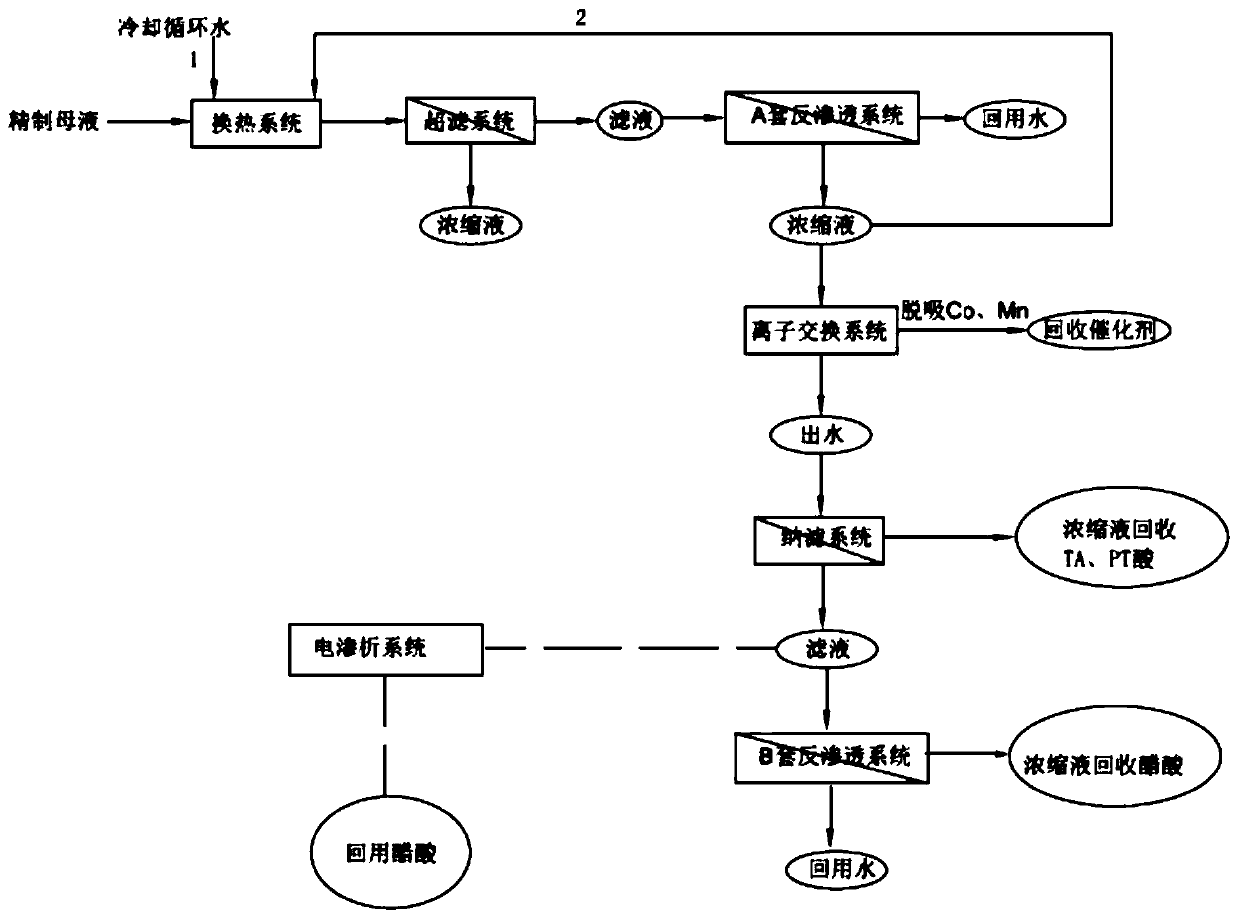

[0081] The temperature of the refined PTA mother liquor drops to 80°C after flash evaporation. At this time, the concentration of PT acid in the mother liquor is 50ppm, the content of TA is 20ppm, the content of acetic acid is 2500ppm, the content of cobalt ion is 4ppm, the content of manganese ion is 5ppm, the content of iron ion is less than 0.5ppm, and the content of nickel is less than 0.5ppm. The ion content is less than 0.1ppm, and the sodium ion content is 20ppm. Add NaOH to adjust the pH to 4.5, and after the heat exchange of the heat exchange system, the temperature is about 45°C. It is pumped into the ultrafiltration system, and it is circulated and concentrated by a circulating pump. The concentrate is discharged to the concentrate tank with agitation.

[0082] The filtrate of the ultrafiltration system enters the ultrafiltration filtrate tank, and then is pumped into the A set of reverse osmosis water recovery system. The ultrafiltration filtrate is intercepted and...

Embodiment 3

[0086] The content of cobalt ion in PTA refined mother liquor is 6ppm, the content of manganese ion is 5ppm, the content of iron ion is less than 0.5ppm, and the content of sodium ion is 50ppm. After exchanging heat between liquid and cold water, the temperature drops to about 45°C, and then it is pumped into the stainless steel membrane ultrafiltration system, and the circulation pump is used to circulate, filter and concentrate, and the concentrated liquid is discharged to the concentrated liquid tank with stirring for recycling.

[0087] The filtrate of the ultrafiltration system enters the ultrafiltration filtrate tank, and then is pumped into the A set of reverse osmosis water recovery system. The ultrafiltration filtrate is intercepted and concentrated by A set of reverse osmosis (RO), the amount of filtrate passing through the A set of reverse osmosis membrane is about 3 / 4 of the influent volume, the TA content in the filtrate is less than 5ppm, and the cobalt ion conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com