A method for preparing bi-2212 precursor powder by suspension sintering

A bi-2212, sintered powder technology, applied in chemical instruments and methods, bismuth compounds, inorganic chemistry, etc., can solve problems affecting powder quality, powder macro segregation, furnace temperature reduction, etc., to improve uniformity and quality, reduce Equipment cost, effect of preventing powder segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

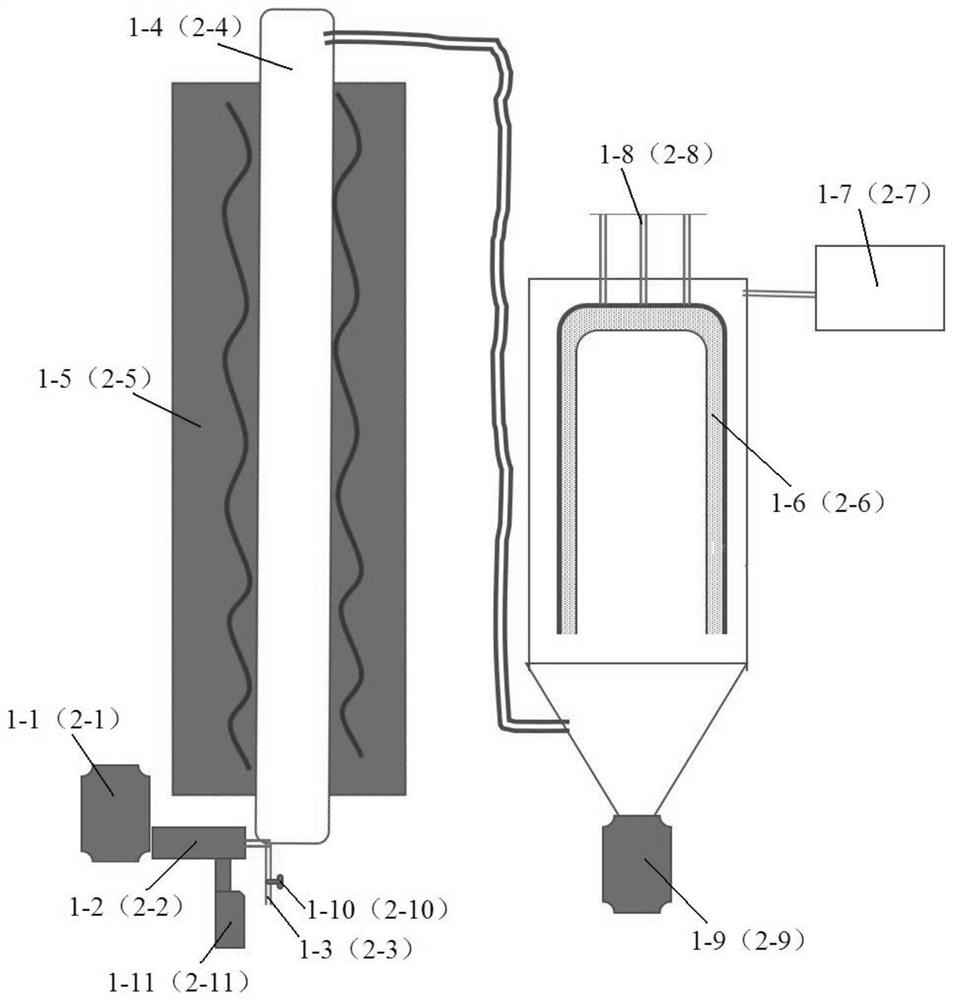

Method used

Image

Examples

Embodiment 1

[0036] This embodiment includes the following steps:

[0037] Step 1. Put Bi 2 o 3 , Ca(OH) 2 , SrCO 3 Mix with CuO according to the mass ratio of Bi:Sr:Ca:Cu=1.95:1.95:0.9:1.95, then prepare a nitrate mixed solution, and then adopt the oxalate co-precipitation method to prepare an oxalate mixed powder;

[0038] Step 2: Put the oxalate mixed powder obtained in step 1 into a box furnace for heating and heat preservation, take it out after cooling with the furnace for grinding, then put it into a continuous rotating automatic sintering furnace for preliminary sintering, and grind it after taking it out to obtain Primary sintered powder; the specific process of heating and heat preservation is as follows: firstly, the temperature is raised to 200°C at a rate of 40°C / h and held for 2h, and then the temperature is raised to 450°C at a rate of 40°C / h and held for 2h; the preliminary sintered The heating rate is 40°C / h, the sintering temperature is 450°C, and the holding time is ...

Embodiment 2

[0043] This embodiment includes the following steps:

[0044] Step 1. Put Bi 2 o 3 , Ca(OH) 2 , SrCO 3 Mix with CuO according to the mass ratio of Bi:Sr:Ca:Cu=2.2:2.2:1:2.2, then be formulated with nitrate mixed solution, and then adopt oxalate co-precipitation method to prepare oxalate mixed powder;

[0045] Step 2: Put the oxalate mixed powder obtained in step 1 into a box furnace for heating and heat preservation, take it out after cooling with the furnace for grinding, then put it into a continuous rotating automatic sintering furnace for preliminary sintering, and grind it after taking it out to obtain Primary sintered powder; the specific process of heating and heat preservation is as follows: firstly, the temperature is raised to 250°C at a rate of 80°C / h and held for 5h, and then the temperature is raised to 500°C at a rate of 80°C / h and held for 5h; the preliminary sintered The heating rate is 80°C / h, the sintering temperature is 500°C, and the holding time is 5h;...

Embodiment 3

[0050] This embodiment includes the following steps:

[0051] Step 1. Put Bi 2 o 3 , Ca(OH) 2 , SrCO 3 Mix with CuO according to the mass ratio of Bi:Sr:Ca:Cu=2:2:0.95:2, then prepare a nitrate mixed solution, and then adopt the oxalate coprecipitation method to prepare an oxalate mixed powder;

[0052] Step 2: Put the oxalate mixed powder obtained in step 1 into a box furnace for heating and heat preservation, take it out after cooling with the furnace for grinding, then put it into a continuous rotating automatic sintering furnace for preliminary sintering, and grind it after taking it out to obtain Primary sintered powder; the specific process of heating and heat preservation is as follows: firstly, the temperature is raised to 230°C at a rate of 60°C / h and held for 3 hours, and then the temperature is raised to 470°C at a rate of 60°C / h and held for 3 hours; the preliminary sintered The heating rate is 60°C / h, the sintering temperature is 470°C, and the holding time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com