Preparation method of multi-edge graphene and prepared aluminum ion battery

An aluminum ion battery and graphene technology, applied in graphene, battery electrodes, secondary batteries, etc., can solve the problems of high production cost and high energy consumption, and achieve the effect that is conducive to mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

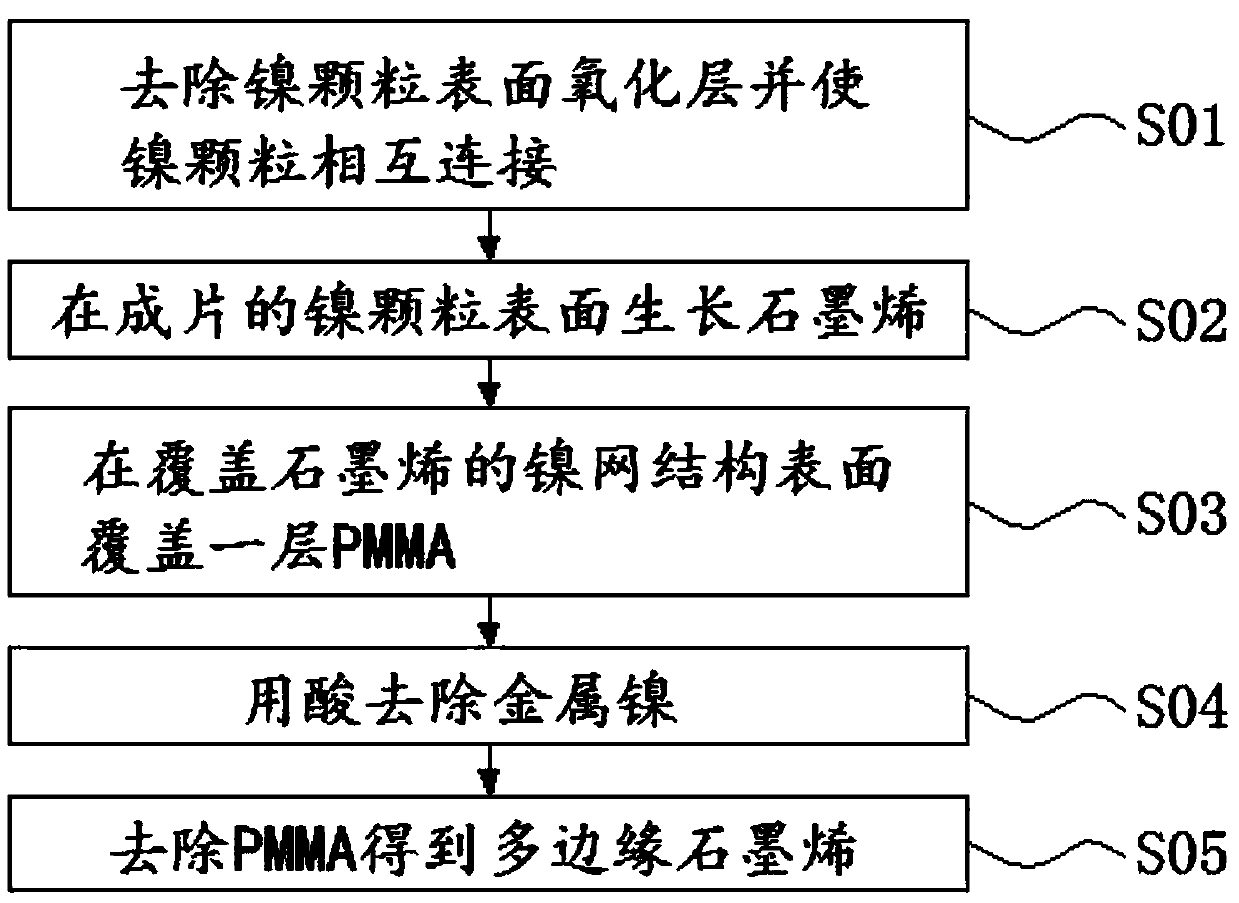

[0034] refer to figure 1 , figure 2 , a preparation method of multi-edge graphene, the preparation method steps are as follows:

[0035] S01, remove the oxide layer on the surface of the nickel particles and connect the nickel particles to each other, use the nickel particles as a three-dimensional template and catalyst, clean the commercially available nickel particles, put them into a quartz boat and put them into a horizontal tube furnace, and then Heating to 400-650°C under vacuum, then continuously feeding argon and hydrogen, annealing at a constant temperature for 10-20min, removing the oxide layer on the surface of the nickel particles and making the nickel particles connected to each other continuously, the size of the nickel particles is 200nm- 4000nm, in view of production cost and energy consumption considerations, the further preferred nickel particle size is 1-3um, the argon flow rate of the tube furnace is 600-800sccm, and the hydrogen flow rate is 70-100sccm; ...

Embodiment 1

[0042] A preparation method of multi-edge graphene, the preparation method steps are as follows:

[0043] S01, remove the oxide layer on the surface of the nickel particles and connect the nickel particles to each other: use 2um nickel particles as a three-dimensional template and catalyst, put the nickel particles into a quartz boat and put it into a horizontal tube furnace, and then heat it under vacuum to 600°C, then continuously feed 700sccm argon and 80sccm hydrogen, anneal at constant temperature for 15 minutes, remove the oxide layer on the surface of nickel particles and make the nickel particles connect to each other continuously;

[0044] S02. Grow graphene on the surface of nickel particles in sheets to form a nickel mesh structure covering graphene: 30sccm methane gas is passed into the reaction tube furnace, and the gas is continuously fed for 5min; Rapid cooling to room temperature at a rate of 200°C min-1 in an atmosphere of air and 80 sccm hydrogen;

[0045] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com