A method and structure for welding bushings on flat tubes

A bushing and flat tube technology, which is applied in the field of welding bushings on flat tubes, can solve problems such as uncontrollable position, asymmetrical solder joints, and inability to penetrate electrodes, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0024] The specific implementation is as follows:

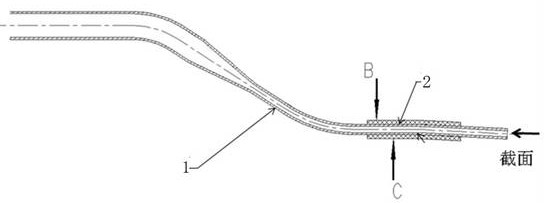

[0025] 1. Shaping: The material of the flat tube 1 is 1Cr18Ni9Ti, which is austenitic stainless steel and has good plasticity and toughness. Cold straightening is used to straighten the bent flat tube so that the skid 3 can be smoothly inserted into the cavity later;

[0026] 2. Plug the skid: Insert the skid 3 into the cavity to ensure that the skid 3 is closely attached to the inner wall of the flat tube 1, to ensure that the skid 3 can bear the pressure of the electrode 4, and to ensure that the flat tube 1 will not be deformed during the welding process.

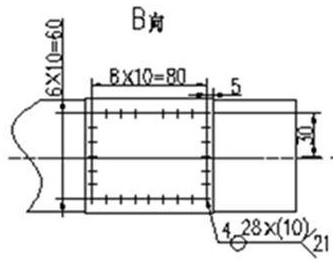

[0027] 3. Welding side A: Attach the middle section of the U-shaped steel wire bushing 2 to the outer wall of the flat tube 1 according to the size requirements. Figure 5 As shown, the steel wire bushing 2 and the A side of the flat tube 1 are welded;

[0028] 4. Add copper sheet 5 and copper wire 6: add copper sheet 5 between the electrode 4 on the A surface and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com