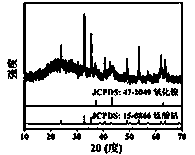

Cobalt titanate@nickel oxide core-shell photocatalytic material as well as preparation method and application thereof

A photocatalytic material, cobalt titanate technology, applied in the field of photocatalysis, can solve problems such as no related reports, and achieve good cycle stability, high-efficiency degradation, and large photoresponse range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of cobalt titanate@nickel oxide (CoTiO 3 @NiO) The preparation method of hierarchical core-shell photocatalytic material, comprises steps as follows:

[0043] (1) Preparation of spinnable precursor sol: Dissolve 0.747 g of cobalt acetate in 8 mL of methanol at room temperature and stir until dissolved; then add 1.02 g of tetra-n-butyl titanate to the above solution, and then add 4 mL of acetic acid was stirred at room temperature for 2 h to obtain a clear solution A; 0.75 g of polyvinylpyrrolidone (PVP) was dissolved in the above solution A and stirred at room temperature for 6 h to obtain the desired spinnable precursor sol.

[0044] (2) Preparation of cobalt titanate submicron ribbons

[0045]Transfer the spinnable precursor sol obtained in step (1) to a 20 mL plastic syringe connected to a stainless steel needle; the stainless steel needle with an inner diameter of 1 mm is connected to a 20 kV power supply; at 25 °C, the air relative humidity is 25% Under co...

Embodiment 2

[0050] A kind of cobalt titanate@nickel oxide (CoTiO 3 @NiO) The preparation method of hierarchical core-shell photocatalytic material, comprises steps as follows:

[0051] (1) Preparation of spinnable precursor sol: Dissolve 0.747 g of cobalt acetate in 8 mL of methanol at room temperature and stir until dissolved; then add 1.02 g of tetra-n-butyl titanate to the above solution, and then add 4 mL of acetic acid was stirred at room temperature for 2 h to obtain a clear solution A; 0.75 g of polyvinylpyrrolidone (PVP) was dissolved in the above solution A and stirred at room temperature for 6 h to obtain the desired spinnable precursor sol.

[0052] (2) Preparation of cobalt titanate submicron ribbons

[0053] Transfer the spinnable precursor sol obtained in step (1) to a 20 mL plastic syringe connected to a stainless steel needle; the stainless steel needle with an inner diameter of 1 mm is connected to a 20 kV power supply; at 25 °C, the air relative humidity is 25% Under c...

Embodiment 3

[0058] A kind of cobalt titanate@nickel oxide (CoTiO 3 @NiO) The preparation method of hierarchical core-shell photocatalytic material, comprises steps as follows:

[0059] (1) Preparation of spinnable precursor sol: Dissolve 0.747 g of cobalt acetate in 8 mL of methanol at room temperature and stir until dissolved; then add 1.02 g of tetra-n-butyl titanate to the above solution, and then add 4 mL of acetic acid was stirred at room temperature for 2 h to obtain a clear solution A; 0.75 g of polyvinylpyrrolidone (PVP) was dissolved in the above solution A and stirred at room temperature for 6 h to obtain the desired spinnable precursor sol.

[0060] (2) Preparation of cobalt titanate submicron ribbons

[0061] Transfer the spinnable precursor sol obtained in step (1) to a 20 mL plastic syringe connected to a stainless steel needle; the stainless steel needle with an inner diameter of 1 mm is connected to a 20 kV power supply; at 25 °C, the air relative humidity is 25% Under c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com