Special pH measurement device for electric generator inner cooling water system and working method thereof

A technology of cold water system and measuring device, which is applied in the direction of material resistance, etc., can solve problems such as interference, and achieve the effect of ensuring the operation cycle, ensuring the accuracy, and ensuring the accuracy of the measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

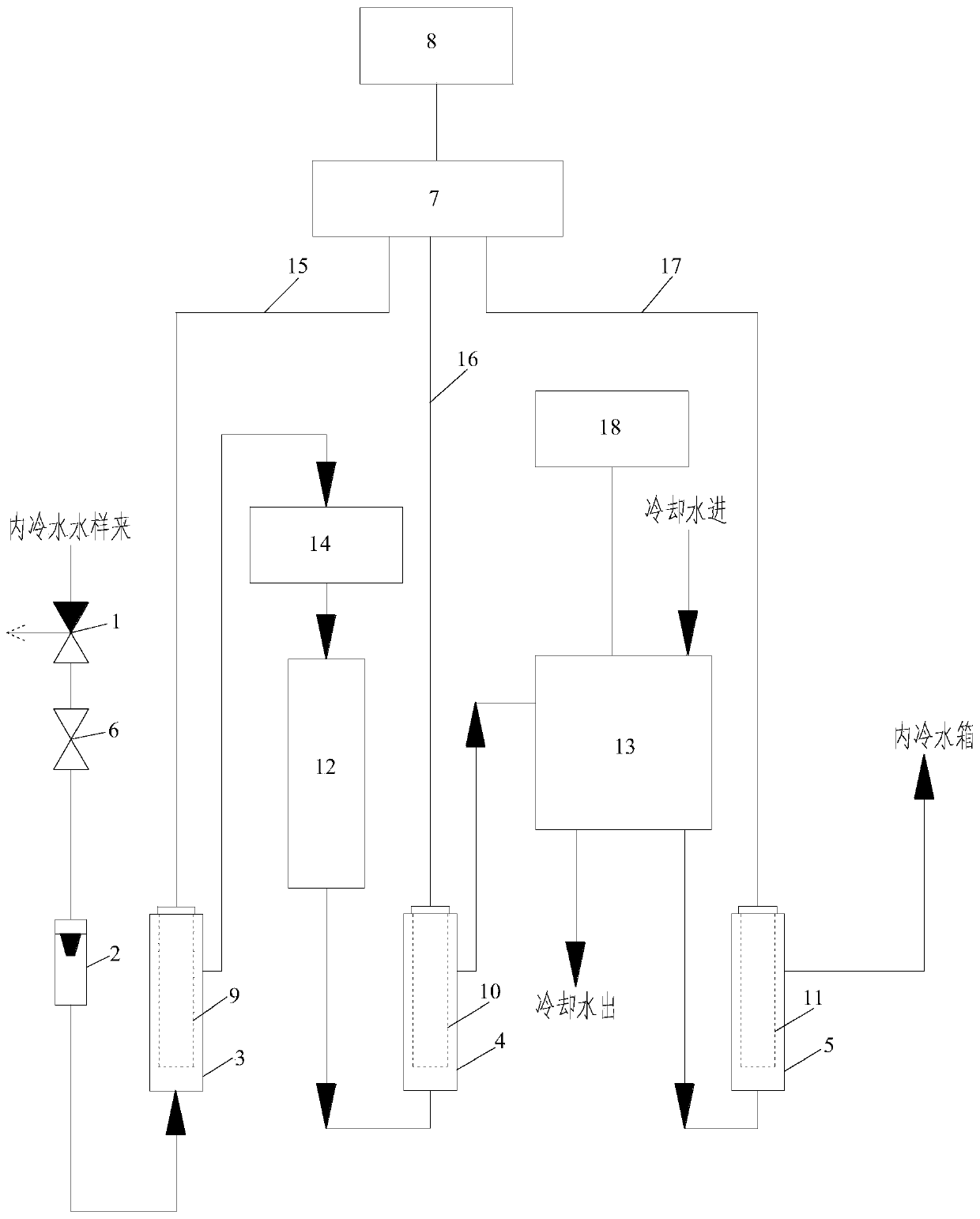

[0026] see figure 2 , the special pH measurement device for the internal cooling water system of the generator in this embodiment includes a flow meter 2, a conductivity flow cell 3, a hydrogen conductivity flow cell 4, a degassed hydrogen conductivity flow cell 5, a flow regulating valve 6, a multi-channel Conductivity meter 7, PLC control panel 8, color-changing cation exchange column 12, carbon dioxide remover 13 and electric regenerative cation exchanger 14, flow regulating valve 6 and flow meter 2 are installed in the water outlet pipe drawn from the inner cooling water cooler of the generator On the sampling pipeline, and flow regulating valve 6 and flow meter 2, conductivity flow cell 3, electric regeneration cation exchanger 14, color-changing cation exchange column 12, hydrogen conductivity flow cell 4, carbon dioxide remover 13 and degassed hydrogen The conductivity flow cell 5 is connected sequentially according to the water flow direction, and the degassed hydroge...

Embodiment 2

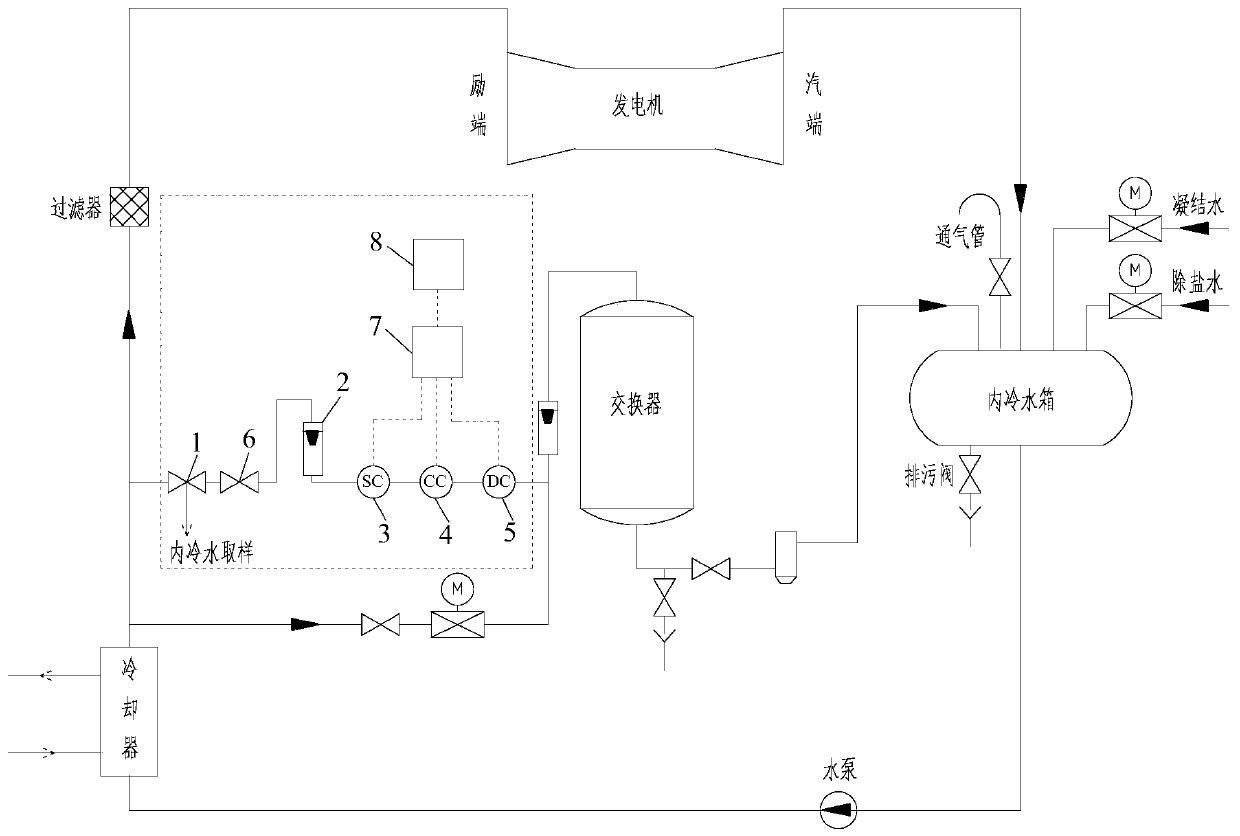

[0034] see figure 1, The special pH measuring device for the inner cooling water system of the generator is installed at the outlet of the cooler of the inner cooling water system of the generator to ensure that the temperature of the water sample will not be too high. The pH measuring device is connected in series with the internal cooling water sampling pipeline through the three-way valve 1, and the measured water samples are returned to the inlet of the exchanger or directly to the internal cooling water tank. When sampling, the flow rate of the water sample in the measurement pipeline will decrease for a short time, and the impact on the measurement can be ignored.

[0035] see figure 2 , the special pH measurement device for the inner cooling water system of the generator consists of a three-way valve 1, a flow meter 2, a conductivity flow cell 3, a hydrogen conductivity flow cell 4, a degassed hydrogen conductivity flow cell 5, a flow regulating valve 6, and a multi-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com