Method for preparing titanium-doped multistage porous silica/nano tungsten oxide composite electrochromic thin film

A nano-tungsten oxide and silicon dioxide technology, applied in the direction of silicon dioxide, silicon oxide, tungsten oxide/tungsten hydroxide, etc., can solve the problem of slow response speed of film discoloration, limited electrochromic film, unfavorable ion diffusion and electron interference Transmission and other issues, to achieve excellent electrochromic performance, simplify the process, improve the effect of electrochemical and optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

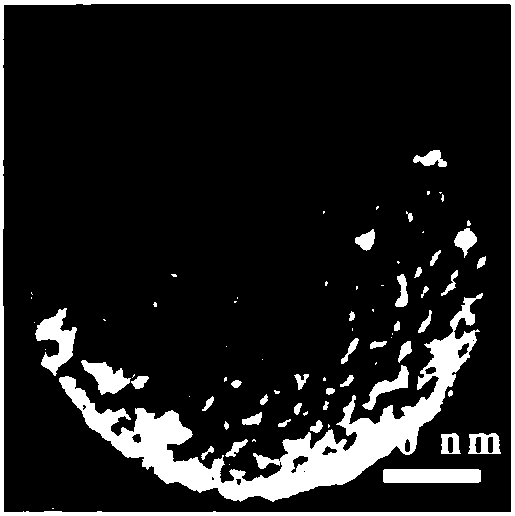

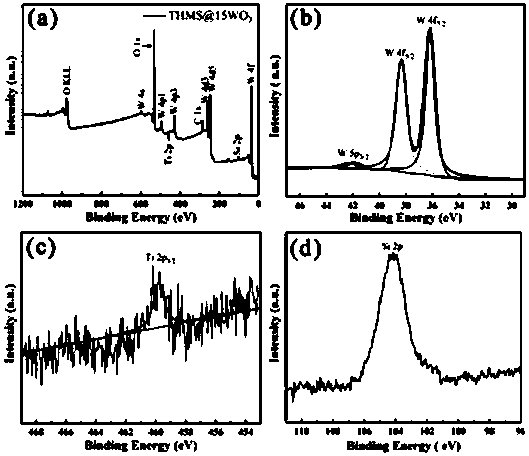

Image

Examples

Embodiment 1

[0043] This embodiment provides a method for preparing a titanium-doped hierarchical porous silica / nano-tungsten oxide composite electrochromic film, which specifically includes the following steps:

[0044] S1. Preparation of composite mesogen template: Dissolve 0.54g cetylpyridinium chloride monohydrate and 4g polyacrylic acid in 25mL molecular water to form a transparent mixed solution, add 4g ammonia water to the mixed solution to obtain composite mesogen template;

[0045]S2. Preparation of titanium-doped hierarchical porous silica microspheres: sequentially mix 2.08g tetraethyl orthosilicate and 1.67mL peroxotitanic acid solution (the preparation method of peroxotitanic acid is as follows: add 0.01mol (1.60 g) sulfuric acid oxygen Dissolve titanium in 25mL molecular water, add 0.04mmol hydrogen peroxide at 2°C, and continue to stir for 2 hours to obtain a peroxotitanic acid solution) Add the complex mesogenic template to form an emulsion, and transfer the emulsion into a...

Embodiment 2

[0050] This embodiment provides a method for preparing a titanium-doped hierarchical porous silica / nano-tungsten oxide composite electrochromic film, which specifically includes the following steps:

[0051] S1. Preparation of composite mesogen template: Dissolve 0.54g cetylpyridinium chloride monohydrate and 4g polyacrylic acid in 25mL molecular water to form a transparent mixed solution, add 4g ammonia water to the mixed solution to obtain composite mesogen template;

[0052] S2. Preparation of titanium-doped hierarchical porous silica microspheres: sequentially mix 2.08 g of tetraethyl orthosilicate and 1.67 mL of peroxotitanic acid solution (the preparation method of peroxotitanic acid is as follows: add 0.01 mol (1.60 g) of sulfuric acid oxygen Dissolve titanium in 25mL molecular water, add 0.04mmol hydrogen peroxide at 2°C, and continue to stir for 2 hours to obtain a peroxotitanic acid solution) Add the complex mesogenic template to form an emulsion, and transfer the em...

Embodiment 3

[0057] This example provides a method for preparing a titanium-doped hierarchical porous silica / nano-tungsten oxide composite electrochromic film. The specific operation steps refer to Example 1, and the differences from Example 1 are as follows:

[0058] S4. Preparation of electrochemical deposition solution: dissolve 0.99g tungsten chloride in 100mL molecular water and stir for 2h, then add 2.8mL hydrogen peroxide and 1.2mL nitric acid in turn, with an interval of 30min, and then stir for 30min to form a peroxytungstic acid solution. Add 0.20 g of titanium-doped hierarchical porous silica microspheres to the solution to obtain an electrochemical deposition solution;

[0059] S5. Constant potential deposition: use the FTO conductive glass cleaned in step S3 as the working electrode, Ag / AgCl as the reference electrode, and the platinum sheet as the counter electrode, and use a three-electrode system to deposit at a constant potential of -0.8V for 5 minutes. After completion, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com